- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.5KW

-

Dimension(L*W*H):

-

730x390x900mm

-

Weight:

-

100 KG

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Condition:

-

New

-

Name:

-

dough mixer

-

Capacity(KG):

-

flour:8kg, 12kg, 20kg, 25kg, 40kg,50kg

-

Material of bowl:

-

stainless steel

-

Speed:

-

two speed

-

Bowl capacity:

-

21 L, 30 L, 40 L, 50 L, to 260L

-

Usage:

-

bread,toast,hamburger,baguettes,moon cake,crisp bread

-

Power Source:

-

electric

Quick Details

-

Brand Name:

-

Daina

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

220V

-

Power:

-

1.5KW

-

Dimension(L*W*H):

-

730x390x900mm

-

Weight:

-

100 KG

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Condition:

-

New

-

Name:

-

dough mixer

-

Capacity(KG):

-

flour:8kg, 12kg, 20kg, 25kg, 40kg,50kg

-

Material of bowl:

-

stainless steel

-

Speed:

-

two speed

-

Bowl capacity:

-

21 L, 30 L, 40 L, 50 L, to 260L

-

Usage:

-

bread,toast,hamburger,baguettes,moon cake,crisp bread

-

Power Source:

-

electric

bread mixing machine dough mixing machine industrial price dough mixer/kitchen mixer dough kneading machine

Spiral mixer Features

1. High & low speed

2. Automatic timer

3. Equipped with bowl safety transparent guard

4. Ideal for all kind of dough

5.

Easy to operate and clean

6.

Requires practically no maintenance

7. Motor overload protection

8. Independent motors for bowl and spiral

9. Stainless steel 304 arm, bowl and dividing plate

10. Ideal mixing process for programmable time sequence, manual intervention possible at any time

11. High torque, dual stage belt drive,Front and rear levelers Automatic over-current protection

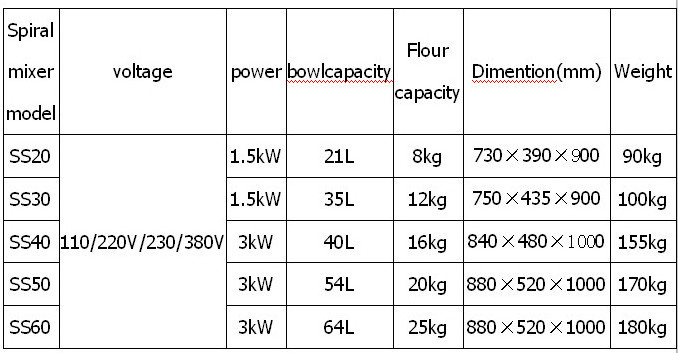

Spiral mixer Specification

Pictures for bread mixing machine dough mixing machine industrial price dough mixer/kitchen mixer dough kneading machine

Wooden Case Packing accord with export standard. After inspection by the quality control department, passing inspection, the machine comprehensive clean-up, and then start packing. First desiccant is placed in the machine And then around the machine with 6 cm thick foam board, winding stretch film for reinforcement, and then add the bubble film. Machine packed in wooden case, and then the metal strip reinforcement. Product packed in containers, depending on the product to be reinforced.

1.Our engineer can serve you a fully installed and operational line, but you should pay it.

2. There is the basic instruction of the mechanical failure and the method how to solve it in the usage instruction clearly.

I will provide you lots of spare parts free

3.( This is only

for the electric oven )

We make guarantee to free service

within a year after selling. It is our responsibility to solve the problem when the machines

have problem by itself, not by the artificialness. We try our best to solve it by phone, if failed, and then our technical e

ngineer can come to your country, but you should pay for their travelling expenses, and we pay for their salary.