- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KAYO

-

Voltage:

-

Customer local voltage

-

Power:

-

12KW

-

Dimension(L*W*H):

-

5000*950*1600mm

-

Weight (KG):

-

420

-

Spraying method:

-

Three color vertical spraying

-

power supply:

-

220V/380V50HZ or customization

-

antistop:

-

Polystyrene deposition equipment

-

After-sales Service Provided:

-

1year

-

Usage:

-

Automatic Powder Coating System

-

Advantage:

-

High Production Efficiency

-

Used for:

-

Powder Coat Curing

-

Production line type:

-

Automatic Spraying Production Line

-

Operation:

-

Operate Easily

-

Technology:

-

Ion Coating+sputtering Coating

Quick Details

-

Machine Type:

-

Powder coating plant pretreatment equipment, Painting Equipment, Coating Equipment

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KAYO

-

Voltage:

-

Customer local voltage

-

Power:

-

12KW

-

Dimension(L*W*H):

-

5000*950*1600mm

-

Weight (KG):

-

420

-

Spraying method:

-

Three color vertical spraying

-

power supply:

-

220V/380V50HZ or customization

-

antistop:

-

Polystyrene deposition equipment

-

After-sales Service Provided:

-

1year

-

Usage:

-

Automatic Powder Coating System

-

Advantage:

-

High Production Efficiency

-

Used for:

-

Powder Coat Curing

-

Production line type:

-

Automatic Spraying Production Line

-

Operation:

-

Operate Easily

-

Technology:

-

Ion Coating+sputtering Coating

Product Description

Specification

|

equipment introduction

|

|

|

|

|

||||

|

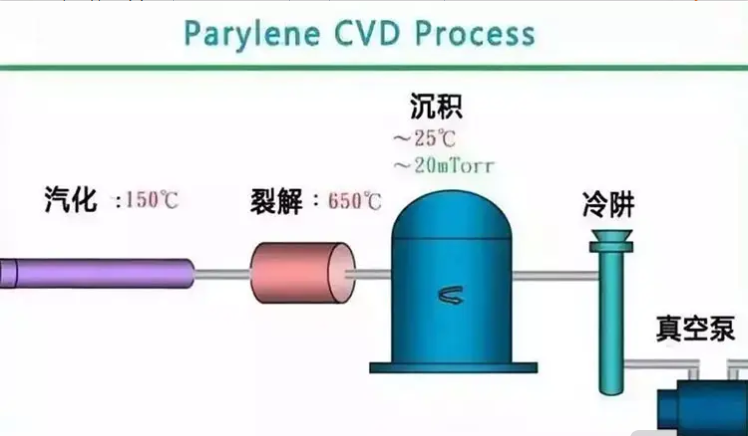

Poly (p-xylene) coating is the coating of a layer of poly (p-xylene) film on the surface of the workpiece by true air phase

deposition (CVD), which is used for waterproof, anti-corrosion and insulation. |

|

|

|

|

||||

|

|

|

|

|

|

||||

operating principle

The entire coating process is divided into three steps: vaporization, cracking and monomer deposition 1. In a vacuum environment, the solid tetrachloro-p-xylene ring dimer is sublimed into a gas at about 150℃ in the evaporation furnace 2. The sublimed dimer gas enters the cracking chamber. At temperatures of about 680 ° C, the molecular bonds of the dimer break, producing an active polyp-xylene monomer.3 At room temperature (25℃), the free polyp-xylene monomer was deposited and polymerized on the surface of the solid substrate to form a conformal film without pinholes.

Solve the following problem

1. With the continuous development of the information industry, magnetic components are becoming more and more miniaturized, and traditional protection methods such as electroplating or epoxy electroplating can no longer achieve reliable protection.

2 .Solve the problem that the uneven type and sharp parts of the liquid coating method can not be coated.

3. Enhance the pressure resistance of the product

|

Summarize

|

|

|

|

item

|

Parylene Coating Machine JY-1000

|

|

|

Product Name

|

Parylene Vacuum Coater

|

|

|

JY-1000Product Model

|

Henan

|

|

|

Brand Name

|

kayo

|

|

|

Working Environment Power Supply

|

380V five-wire, high power 12KW

|

|

|

Ambient Temperature

|

0-40℃

|

|

|

Ambient Humidity

|

<90%

|

|

|

Size

|

Appearance size 5000*950*1500mm, covers an area of about 5 square meters, the installation should be left around the operating

space

|

|

|

Heating Part Sublimation Raw Material Bin

|

Φ125*400mm Capacity: 1000g

|

|

|

Heating Temperature High

|

200℃

|

|

|

Temperature Stability

|

<2℃

|

|

|

Cracking Heating Temperature

|

<1200℃

|

|

|

Insulation Heating Temperature

|

<300℃

|

|

|

Main Body Chamber Size

|

Φ800 x L1000

|

|

|

Vacuum Pumping Speed

|

30L/s, 3.7Kw x 4P x 380V according to specific requirements

|

|

|

Cold trap

|

up to -90℃

|

|

company introduction

Anyang Jiayou Amorphous Technology Co., Ltd. is a high-tech enterprise integrating research and development, sales, production and

service. Paililin vacuum coating machine is one of the products developed and manufactured by the company. The company has good

cooperation with many universities, research institutes and industry experts at home and abroad, relying on its strong technology

research and development team, the company continues to improve the manufacturing capacity of Prelin equipment, refined coating

technology, to provide our customers with better quality Prelin coating processing technology and equipment sales.

service. Paililin vacuum coating machine is one of the products developed and manufactured by the company. The company has good

cooperation with many universities, research institutes and industry experts at home and abroad, relying on its strong technology

research and development team, the company continues to improve the manufacturing capacity of Prelin equipment, refined coating

technology, to provide our customers with better quality Prelin coating processing technology and equipment sales.

FAQ

1. who are we?

We are based in Henan, China, start from 2011,sell to South Asia(15.00%). There are total about null people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Nanocrystalline common-mode inductor core,Core for DC resistant current transformers,Current transformer core,Cobalt-based amorphous alloy strip,Iron-based amorphous filter inductor core

4. why should you buy from us not from other suppliers?

"To provide reliable quality, competitive products in price, and common development with customers" is our enterprise vision.AnYang Kayo is one of the leaders in the amorphous industry in northern China. In the past ten years, Kayo has been working hard ,

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C;

Language Spoken:English

We are based in Henan, China, start from 2011,sell to South Asia(15.00%). There are total about null people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Nanocrystalline common-mode inductor core,Core for DC resistant current transformers,Current transformer core,Cobalt-based amorphous alloy strip,Iron-based amorphous filter inductor core

4. why should you buy from us not from other suppliers?

"To provide reliable quality, competitive products in price, and common development with customers" is our enterprise vision.AnYang Kayo is one of the leaders in the amorphous industry in northern China. In the past ten years, Kayo has been working hard ,

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C;

Language Spoken:English

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches