- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

3600 KG

-

Marketing Type:

-

New Product

-

Feed size(mm):

-

100-200

-

Discharge size(mm):

-

≤3

-

Production capacity:

-

20-180t/h

-

Motor power:

-

55kw+75kw

-

After Warranty Service:

-

1 year

-

Product name:

-

Two-stage crusher

-

Advantage:

-

High Efficiency Low Energy

-

Dimensions:

-

customizable

-

Application:

-

stone crushing

Quick Details

-

Capacity(t/h):

-

20-180t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RD

-

Weight:

-

3600 KG

-

Marketing Type:

-

New Product

-

Feed size(mm):

-

100-200

-

Discharge size(mm):

-

≤3

-

Production capacity:

-

20-180t/h

-

Motor power:

-

55kw+75kw

-

After Warranty Service:

-

1 year

-

Product name:

-

Two-stage crusher

-

Advantage:

-

High Efficiency Low Energy

-

Dimensions:

-

customizable

-

Application:

-

stone crushing

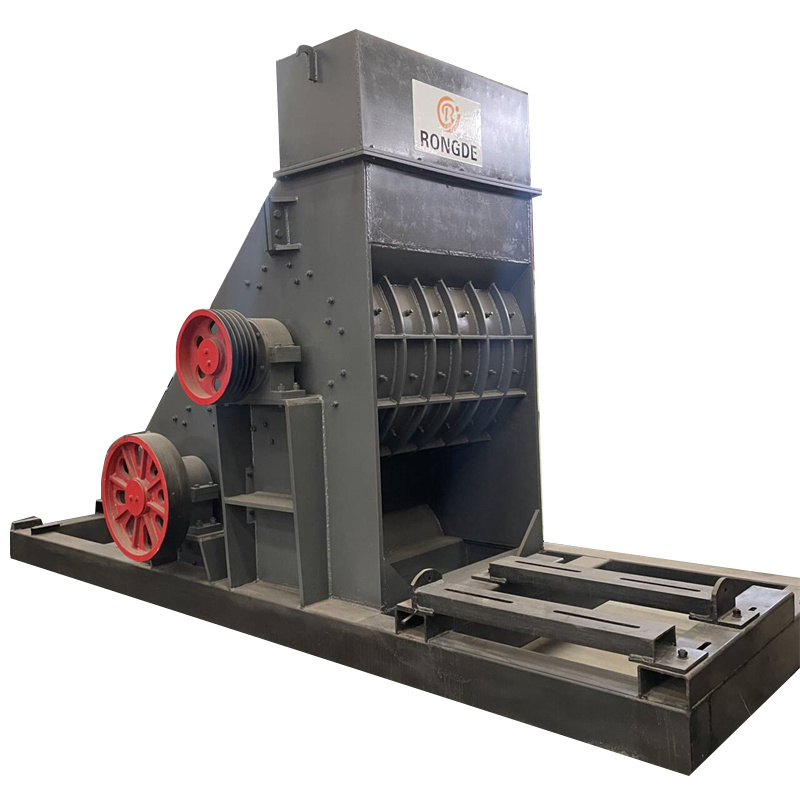

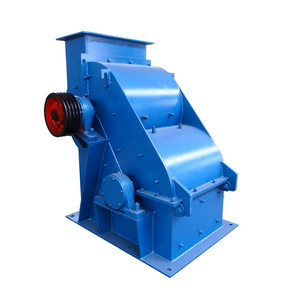

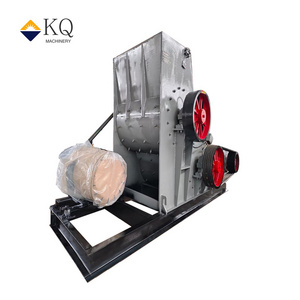

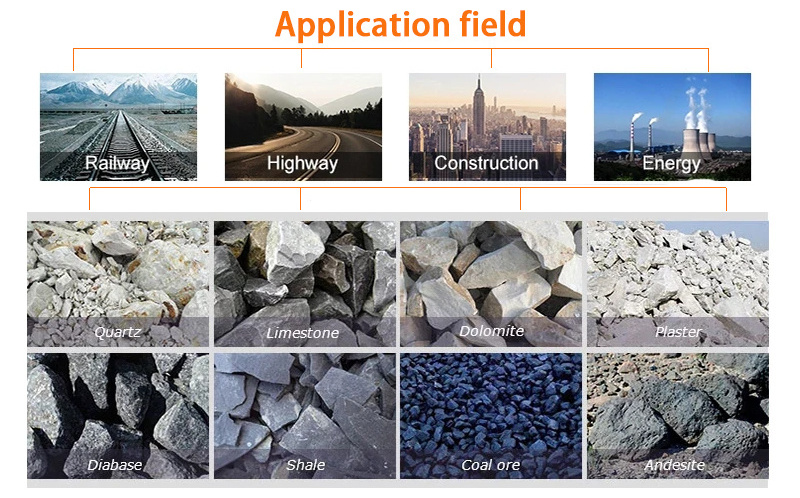

Products Description

Two-stage Crusher is mainly composed of silos, conveying devices, high-speed hammers, motors, brackets and other parts. Two-stage Crusher has a wide range of applications. It is mainly applied to the crushing of coal gangue, carbon mud, coal slime, coal, and clean coal. Two-stage Crusher has no screen, no residual residue, 100% yield. There is no limit on material humidity and feed particle size. Slime regardless of the shape can be directly into the machine crushing.

Can be broken on pebbles, coal gangue, shale, cinder, limestone, ore, slag, steel slag, construction waste and other different raw materials . And the discharge particle size is 2-3mm.

Details Images

1. Two-stage crusher is suitable for the fine crushing of crisp materials with no blockage, low powder dust pollution and low noise.

2. Two-stage crusher shortens the time that the materials stay in the crushing chamber, thus extending the service life of the easy-wearing parts.

3. The installation is very convenient, thus greatly improving the flexibility of the equipment.

2. Two-stage crusher shortens the time that the materials stay in the crushing chamber, thus extending the service life of the easy-wearing parts.

3. The installation is very convenient, thus greatly improving the flexibility of the equipment.

Our Advantages

Two-stage crusher design, no screen, no water content requirements, will not appear paste blocking screen. Two-stage crusher design has no grate bottom, no strict requirements on material moisture content, there is no paste blocking sieve plate problem, there is no fine powder can not be discharged in time, repeated crushing problem, so high crushing efficiency, there is no invalid hammer wear phenomenon. Only need one person can easily open and close, not only light and fast and safe and reliable, easy maintenance.

Product Paramenters

|

specification

|

feed size(mm)

|

discharge size(mm)

|

production capacity(t/h)

|

motor power

|

dimensions(mm)

|

|

ZPC600*600

|

≤100

|

≤3

|

20-30

|

22kw*2

|

2300*6500*1680

|

|

ZPC800*600

|

≤120

|

≤3

|

35-55

|

45kw+55kw

|

2500*870*1700

|

|

ZPC1000*800

|

≤160

|

≤3

|

60-90

|

55kw+75kw

|

3500*8702*1800

|

|

ZPC1200*1000

|

≤200

|

≤3

|

80-120

|

90kw+110kw

|

3800*1800*2400

|

|

ZPC1400*1200

|

≤200

|

≤3

|

100-140

|

132kw+160kw

|

4400*2300*2600

|

|

ZPC1600*1400

|

≤200

|

≤3

|

120-180

|

160kw+200kw

|

4400*2300*2600

|

Hot Searches