- Product Details

- {{item.text}}

Quick Details

-

Power:

-

4kw

-

Weight (KG):

-

2000

-

Product name:

-

Decoiler

-

Usage:

-

Metal Sheet Strip Coil

-

Material:

-

Galvanized Steel

-

Keyword:

-

Automatic Straightener Coil Feeder

-

Machine Type:

-

Hydraulic decoiler

-

Production Capacity::

-

15m/min

-

Coil inner diameter:::

-

450mm-650mm

-

Maximum width of coiling::

-

1250mm

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wadley

-

Voltage:

-

380v

-

Power:

-

4kw

-

Weight (KG):

-

2000

-

Product name:

-

Decoiler

-

Usage:

-

Metal Sheet Strip Coil

-

Material:

-

Galvanized Steel

-

Keyword:

-

Automatic Straightener Coil Feeder

-

Machine Type:

-

Hydraulic decoiler

-

Production Capacity::

-

15m/min

-

Coil inner diameter:::

-

450mm-650mm

-

Maximum width of coiling::

-

1250mm

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

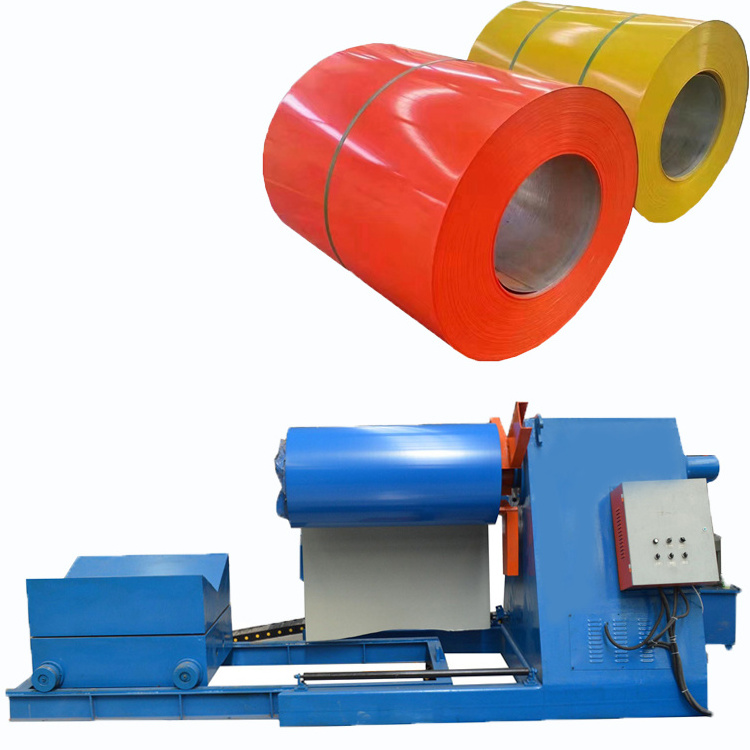

Full-automatic Steel Coil Hydraulic Decoiler Metal Sheet Automatic Coil Uncoiler Machine 5 ton for sale

This auto uncoiler is used to support the coil for roll forming machine

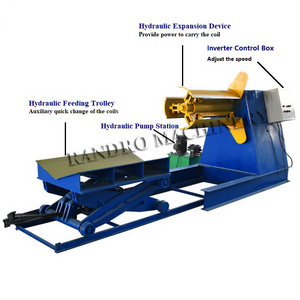

1. Automatic uncoiler is an auxiliary equipment for roll forming machine. it is composed of feed main machine, hydraulic station and control system. When it works together with roll forming machine and auto stacker, they make up a completely steel panel production line.

2. The working process is loading coil→expanding to fix the coil→uncoiling→feeding the sheet into roll forming machine. There is a sensor, to keep uncoiler goes at the same speed as roll forming machine.

3.The advantage for automatic uncoiler is, highly automatic, high producing efficiency, and low labor cost.

Product characteristics

(1) Automatic Operation

Decoiler rotation is automatically loop arm controlled. The loop arm controls variable speed operation, providing smooth stops and starts. Variable speed reduces decoiler.

(2) Safety

The decoiler rotary drive system and mandrel expansion power is fully guarded. The pendant control allows disabling automatic rotation during coil loading.

(3) Electrical Requirements

Three phase electrical supply is required. Equipment can operate from 220-575 volts in 50 or 60 hz.

(4) Construction

Construction includes steel plate and heavy structural sections. Plate seams are seal welded. Structural bracing is included where required. Mandrel expansion & contraction is by a link system including bronze bearings.

(5) Decoiler Finish

After fabrication completion, the decoiler framework is machine cleaned and powder coated prior to electro-mechanical assembly.

(6) Coil Car Option

A coil car with weight capacity matched to the specified decoiler can be included. The coil car includes a 'v' shaped surface to center coils during movement. The coil car includes sufficient vertical travel to touch the mandrel lower surface when fully extended. The powered coil car moves along steel tracks mounted within the decoiler base. Hydraulic check valve prevents vertical coil drop in the event of hydraulic pressure loss.

(7) Installation

The decoiler and coil car can be installed by placing on a typical industrial concrete foundation and drilling holes for concrete expansion bolts.