- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RO-CHAIN

-

Voltage:

-

220/380V 50HZ

-

Power:

-

4KW

-

Dimension(L*W*H):

-

2200*990*1700mm

-

Weight:

-

1300 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Paper Cup Making Machine Automatic

-

Finished Products:

-

Colorful Paper Cup

-

After-sales Service Provided:

-

Video Technical Support Online Support

-

Advantage:

-

Easy Control

-

Speed:

-

70-90pcs/min

-

Raw material:

-

PE Coated Paper

-

Color:

-

Customized Color

-

Paper Cup Size:

-

2 ~16 OZ (50ml~330ml Mould Exchangeable)

-

Feature:

-

Easy Opreation

-

Total Power:

-

4kw

Quick Details

-

Production Capacity:

-

70-80 pcs/min

-

Processing Type:

-

forming machine

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

RO-CHAIN

-

Voltage:

-

220/380V 50HZ

-

Power:

-

4KW

-

Dimension(L*W*H):

-

2200*990*1700mm

-

Weight:

-

1300 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Paper Cup Making Machine Automatic

-

Finished Products:

-

Colorful Paper Cup

-

After-sales Service Provided:

-

Video Technical Support Online Support

-

Advantage:

-

Easy Control

-

Speed:

-

70-90pcs/min

-

Raw material:

-

PE Coated Paper

-

Color:

-

Customized Color

-

Paper Cup Size:

-

2 ~16 OZ (50ml~330ml Mould Exchangeable)

-

Feature:

-

Easy Opreation

-

Total Power:

-

4kw

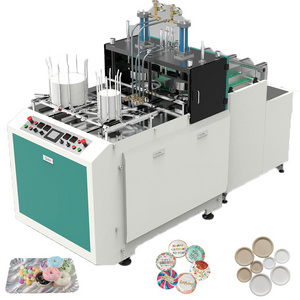

L X P -70-N

Automatical Open Cam Direct Bottom&Single Plate Paper Cup Machine

E c o n om ic / H igh speed / H igh efficiency

DESCRIPTION

LXP-70 -N Paper cup making machine is open cam and single plate.Machine with automatic oil lubrication system ,combine gear system with cam system ,machine size is small , speed is fast , operate is easy ,used for producing advertising cups , drinking cups , coffee cups , tea cups etc.

LXP-70-N is an upgraded version of LXP-70 .

ADVANTAGE

1. The machine adopts the structure of combination of gear system and cam system which can improve

the machine after-sales service according to Traditional gearbox . It make t he machine run more stably under high speed operation .

2. Machine with small size,easy for delivery and setting,machine parts under h igh precision and small noise

3. 10mm thickness for machine bottom steel plate instead of before U-steel ,make the machine more stronger ,running more stably ,reduce the reject rate.

4. LXP-70-N adds a paper cutting system on the basis of LXP-70 to facilitate waste paper recycling.

5. Add a heating air gun to help paper cups stick together.

6. U se the linear bearing instead of before shaft bearing , the feeding system keeps running more smoothly .

7. M achine body material was updated, we use square steeel instead of before angle steel ,

so that machine is more stonger and more stable.

DETAIL IMAGE:

MAIN TECHICAL PAREMETER

|

General Power |

4 kw |

|

Paper Request |

150-400g/m² (single PE coated paper&double PE coated paper) |

|

Voltage Supply |

220V50HZ 380V50HZ or customized |

|

Cup Size |

2- 9 oz |

|

Speed |

70-90 pcs/min |

|

Weight |

1300 KGS |

|

Machine Measurement |

2 130 * 112 0* 1600 mm |

|

woodenbox Measurement |

2300*1360*1850mm |

COMPONENTS BRAND

|

NAME |

BRAND |

|

main motor |

libao (china) |

|

knurling motor |

libao (china) |

|

frequency convernter |

zhongchen(china) |

|

contactor |

Schneider |

|

relay |

yijia(china) |

|

Circuit breaker |

CHINT(china) |

|

solid relay |

beijing (china ) |

|

transformer |

renmin electrical(china ) |

|

capacitance |

Toshiba( Japan) |

|

button |

baoya (china) |

|

ultrasonic |

HENXA |

MACHINE WORKSHOP

PACKAGING SHIPPING

FAQ

Q1. Are you trading company or manufacturer?

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q5. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.