- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Agriculture, for animal manur

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FURUI, Furui Animal Manure Dewatering Machine

-

Capacity:

-

10-15 M³/H, 15-20 M³/H, 20-25 M³/H

-

Power supply:

-

4kw, voltage customized

-

size:

-

2000*600*1300, 2200*610*1350, 2400*800*1300 mm

-

Screen inner diameter:

-

200mm

-

water outler diameter:

-

110mm

-

weig:

-

370kg, 560kg, 720kg

-

feed inlet diameter:

-

76mm

-

Usage:

-

Cow Dung, Chicken Manure, Pig Poultry Dewatering

Quick Details

-

Weight (KG):

-

300

-

Marketing Type:

-

New Product 2022

-

Type:

-

Farm Equipment, Manure dewater use Farm Equipment

-

Use:

-

Agriculture, for animal manur

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FURUI, Furui Animal Manure Dewatering Machine

-

Capacity:

-

10-15 M³/H, 15-20 M³/H, 20-25 M³/H

-

Power supply:

-

4kw, voltage customized

-

size:

-

2000*600*1300, 2200*610*1350, 2400*800*1300 mm

-

Screen inner diameter:

-

200mm

-

water outler diameter:

-

110mm

-

weig:

-

370kg, 560kg, 720kg

-

feed inlet diameter:

-

76mm

-

Usage:

-

Cow Dung, Chicken Manure, Pig Poultry Dewatering

New style animal drying cow dung dewatering machine/waste manure screw press solid liquid separator / Farm/restaurant Machinery Test Report Automatic Grade 1 Years Warranty Video Technical Support Chicken Manure Dewatering Machine Poultry Manure Removal manure dewatering machine

1. Breif introduction of chicken cow dung and pig manure dewatering machine

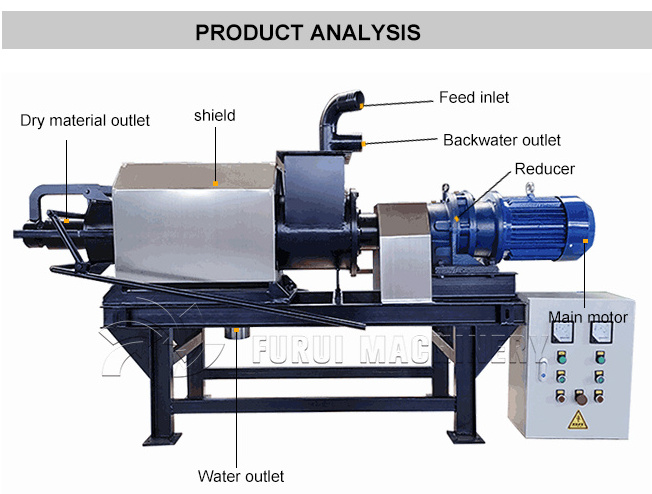

Screw dewatering for animal manure is mainly composed of control cabinet, pipeline, pumps,body, mesh screen, main motor, reducer, Feed inlet, water outlet, dry material outlet and other parts. This equipment is widely used and has been widely used and ecognited in the market.

The manure dewatering machine is laso named solid-liquid separator, dry and wet separator, dung drying machine, manure cleaning machine, ect.

2. Main technical parameters

|

Model |

FR-180 |

FR-200 |

FR-280 |

|

Voltage |

380V |

380V |

380V |

|

Power |

4kw |

4kw |

5.5kw |

|

Machine Size |

2000*600*1300mm |

2200*610*1350mm |

2400*800*1300mm |

|

Weig |

340kg |

510kg |

680kg |

|

Capacity |

10-15 M³/H |

15-20 M³/H |

20-25 M³/H |

|

Screen inner diameter |

180mm |

200mm |

280mm |

|

Feed inlet diameter |

76mm |

76mm |

76mm |

|

Water outlet diameter |

110mm |

110mm |

110mm |

| Body Material |

Carbon steel & 304 stainless steel |

Nodular cast iron& 304 stainless steel |

Nodular cast iron& 304 stainless steel |

3. Scope of application

The manure dewatering machine is a kind of livestock and poultry excrement which is diluted according to a certain ratio, is pumped into the extruder through a high-bar sewage pump, and is filtered by a screw extrusion and a sieve to separate the solid and liquid substances.

Liquid organic fertilizer can be directly used for crop utilization and absorption.

Solid organic fertilizer can be transported to the area lacking in fertilizer, and can also play a role in improving soil structure. At the same time, it can be made into organic compound fertilizer through fermentation.

The machine can be widely used as a slag separation of chicken, cattle, horse and various intensive farms for high-concentration organic sewage such as animal manure, distiller's grains, dregs, starch residue, sauce residue and slaugerhouse.

As different materials has different capacity, we have tested the output of several different materials for your reference.

4. Features and advantages of the dewatering machine

1. The solid-liquid separator machine adopts high-strength screw shaft, anti-corrosion alloy double spiral blade and screen mesh made of stainless steel, and the spiral blade adopts manganese treatment, which is twice the service life of other similar products.

2. The mother liquor used for fermentation is subjected to solid-liquid separation, and the separated biogas residue has a water content of 30-40% or less, and the solid wastis separated.

3. The manure dewatering machine can be widely used as a slag separation of chicken, cattle, horse and various intensive farms for high-concentration organic sewage such as animal manure, distiller's grains, dregs, starch residue, sauce residue and slaugerhouse.

5. Function of Manure Dewatering Machine

1.The separation speed of the manure dewatering machine of slag liquid is fast, the moisture content of the separated slag is between 35-65%, the slag amount and water content can be adjusted, and it can be applied to different feeds for transportation. Its solid content is very suitable as a raw material for fish feed and organic fertilizer.

2.This manure dewatering machine has strong decontamination ability, no clogging and easy cleaning. The treated solid waste water, chemical oxygen demand, total oxygen consumption, nitrogen and phosphorus removal rate can be between 54-95%.

3.The manure dewatering machineconsumes less power. Easy to operate, just press the start and stop button to operate .

Outlet

There is a spring at the exit to adjust the dryness and wetness of the extruded material, and separate the solid manure and manure with a water content of only 35%.

Screen Mesh

Screen mesh made of stainless steel. Made by multiple programs. For different materials, you can replace the screen with different density to achieve the desired effect.

Screw

Fully welded spiral design, 304 material, more corrosion-resistant

The machine adopts high-strength screw shaft, anti-corrosion alloy double-coil blade, which is twice the service life of other similar products.

Cycloidal Reducer

Compact and small size.Smooth operation and low noise.Long service life, the main parts are made of ductile iron material, high strength is obtained by quenching treatment (HRC58~62), and some transmission contact adopts rolling friction, so it has long durability and long service life

.

6. working principle

It separates the moisture and the animal manure by screw extruding extrusion technology.

First, When the cutting feed pump pushs the animal manure to the screw dewatering machine through the pipeline, the dewatering machine start to work.

The screw gradually pushes the animal manure to the front of the body. And at the same time, increases the pressure, forcing the moisture in the raw material to squeeze out from Mesh screen, flowing out of the drain pipe .

7. Features and advantages

(1) Save space, Low speed, operate easily, low cost, fast investment recovery, environmental protection, low power consumption, suitable for continuous operation.

(2) The material of important parts are 304 stainless steel, such as screw, screen, etc.

1. Packing: PP film wrapped around the machine and carefully packed in wooden case to focus on protecting damageable parts.

2. Shipping: From port of Shenzhen, Shanghai, Qingdao, Guangzhou,etc. We also accept land, air, sea transport and international multimodal transport.

3. Clearance: Our long history makes us the one of the first and most knowledgeable providers of the equipment, our main customers hail from; Canada, the United States, Brazil, Argentina, Japan, Philippines, Australia, Russia, Thailand, the UAE, Poland, Spain, Germany, India, etc.

1.After-sale service:

We provide 12 months' warranty(After the warranty, we can provide life-long repair service).

2. Customization:

We make customized diesel engine crusher plastic machine.

3. Design:

* Mechanical Design: We make a good mechanical design to ensure they can operate without

any frictions, so that it can have a long service life.

* If you have some special scenes in your mind, you can draw it down and we can produce the your pictures Also, we can make the movie scenes!

* Inspection: we have a strict Quality Inspection Department, and every machine would be tested before delivery.

Tel/ WhatsApp/ WeChat: +86-15503747612