- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HP115EDM

-

Polymer Structure:

-

Styrene-DVB

-

Appearance:

-

yellow spherical beads

-

Ionic form:

-

H+ OH-

-

Moisture Content %:

-

50-70%

-

Particle Size Range 0.315-1.25mm:

-

≥95

-

Uniformity Coefficient max.:

-

≤1.6

-

Temperature Limit:

-

60

-

Whole Spherical Rate After Attrition %:

-

≥90

Quick Details

-

Purity:

-

99.99%

-

Place of Origin:

-

China

-

Brand Name:

-

HELPER

-

Model Number:

-

HP115EDM

-

Polymer Structure:

-

Styrene-DVB

-

Appearance:

-

yellow spherical beads

-

Ionic form:

-

H+ OH-

-

Moisture Content %:

-

50-70%

-

Particle Size Range 0.315-1.25mm:

-

≥95

-

Uniformity Coefficient max.:

-

≤1.6

-

Temperature Limit:

-

60

-

Whole Spherical Rate After Attrition %:

-

≥90

HP115EDM ST-DVB

Mixed bed resin

|

Polymer Structure

|

Styrene-DVB

|

|

Appearance

|

yellow spherical beads

|

|

Type

|

Gel mixed bed resin

|

|

Ionic form

|

H+ /OH-

|

|

Functional group

|

|

|

MoistureContent %

|

50-55% (H+ )

60-70%(OH-) |

|

Total Exchange Capacity Eq/L

Cation (in sodium form) Anion (in chloride form) The Ratio Cation:Anion |

2.0 1.3 1:15 |

|

Particle Size Range 0.315-1.25mm

|

≥95

|

|

Uniformity Coefficient max.

|

≤1.6

|

|

Reversible Swelling Na →H max %

|

|

|

Shipping Weight g/ml

|

0.70-0.74

|

|

Temperature Limit ℃

|

60

|

|

Whole Spherical Rate After Attrition %

|

≥90

|

|

|

|

|

||||

|

|

|

|

||||

|

Benzene Removal

|

|

|||||

|

Halogenated hydrocarbons adsorbent

|

|

|||||

|

Ester Removal

|

|

|||||

|

|

|

|

|

|||

|

|

|

|

||||

|

Leaded Acid Purification

|

||||||

|

Metal Acid Purification

|

|

|||||

|

COD contained Acid Purification

|

||||||

|

Copper contained Acid Purification

|

||||||

|

Iron contained Acid Purification

|

|

|||||

|

|

|

|

|

|||

|

|

|

|

||||

|

Fluorine Removal

|

||||||

|

Phosphate Removal

|

||||||

|

Total Nitrogen Removal

|

||||||

|

Ammonia Nitrigen Removal

|

|

|||||

|

|

|

|

|

|||

|

|

|

|

||||

|

Oil Removal

|

|

|||||

|

Phenol Removal

|

||||||

|

Sulfonated Acid Removal

|

||||||

|

Benzoic Acid Organics Removal

|

||||||

|

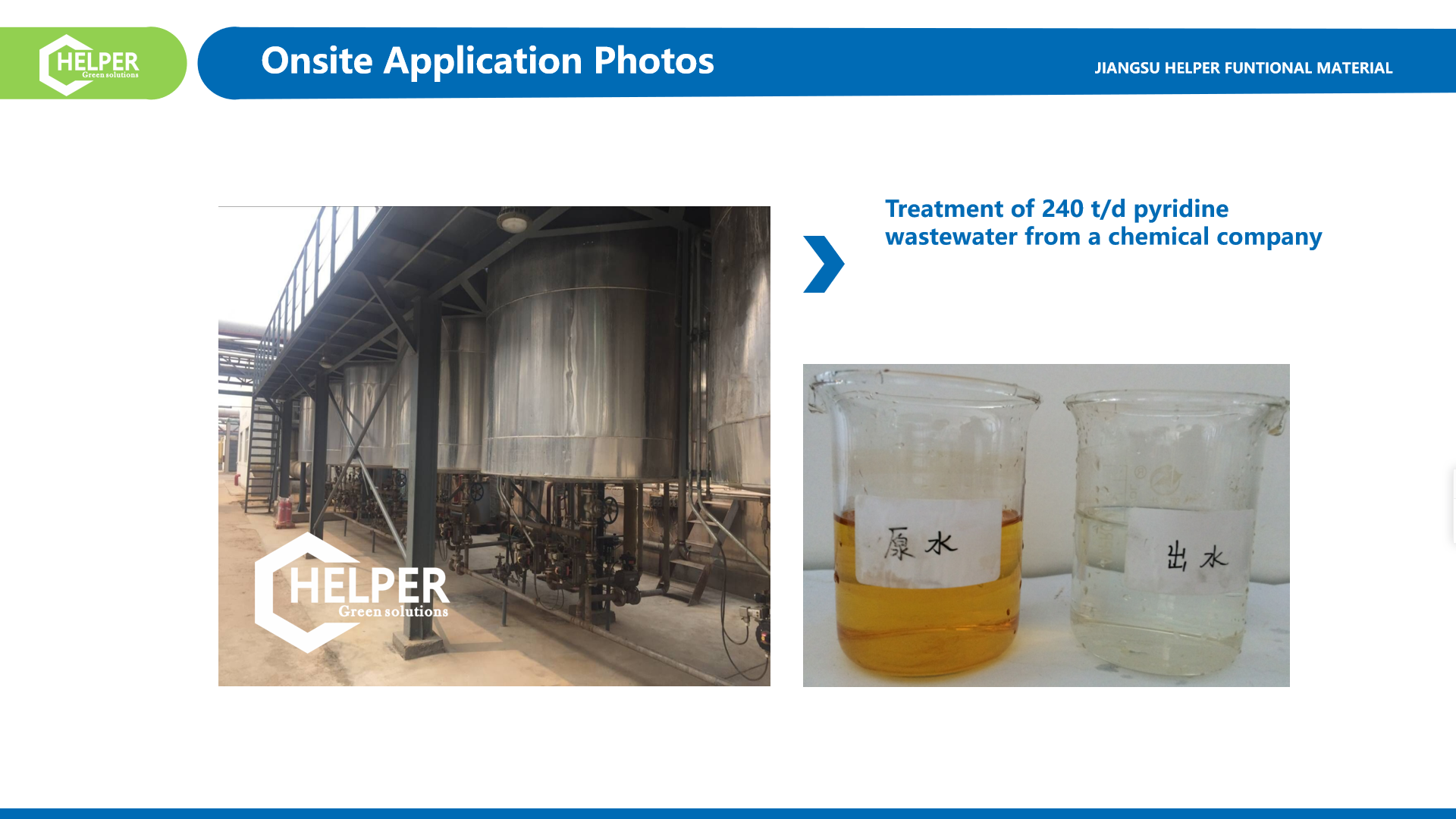

Pyridine Removal

|

HP334

|

|||||

|

Organic Acid Purification

|

||||||

|

Organic Phosphrous Removal

|

||||||

|

|

|

|

|

|||

|

|

|

|

||||

|

Nickel Removal

|

||||||

|

Lead Removal

|

||||||

|

Copper Removal

|

||||||

|

Cobalt Extraction

|

||||||

|

Iron Removal

|

HT609

|

|||||

|

Arsenic Removal

|

||||||

|

Lithium Extraction

|

|

|||||

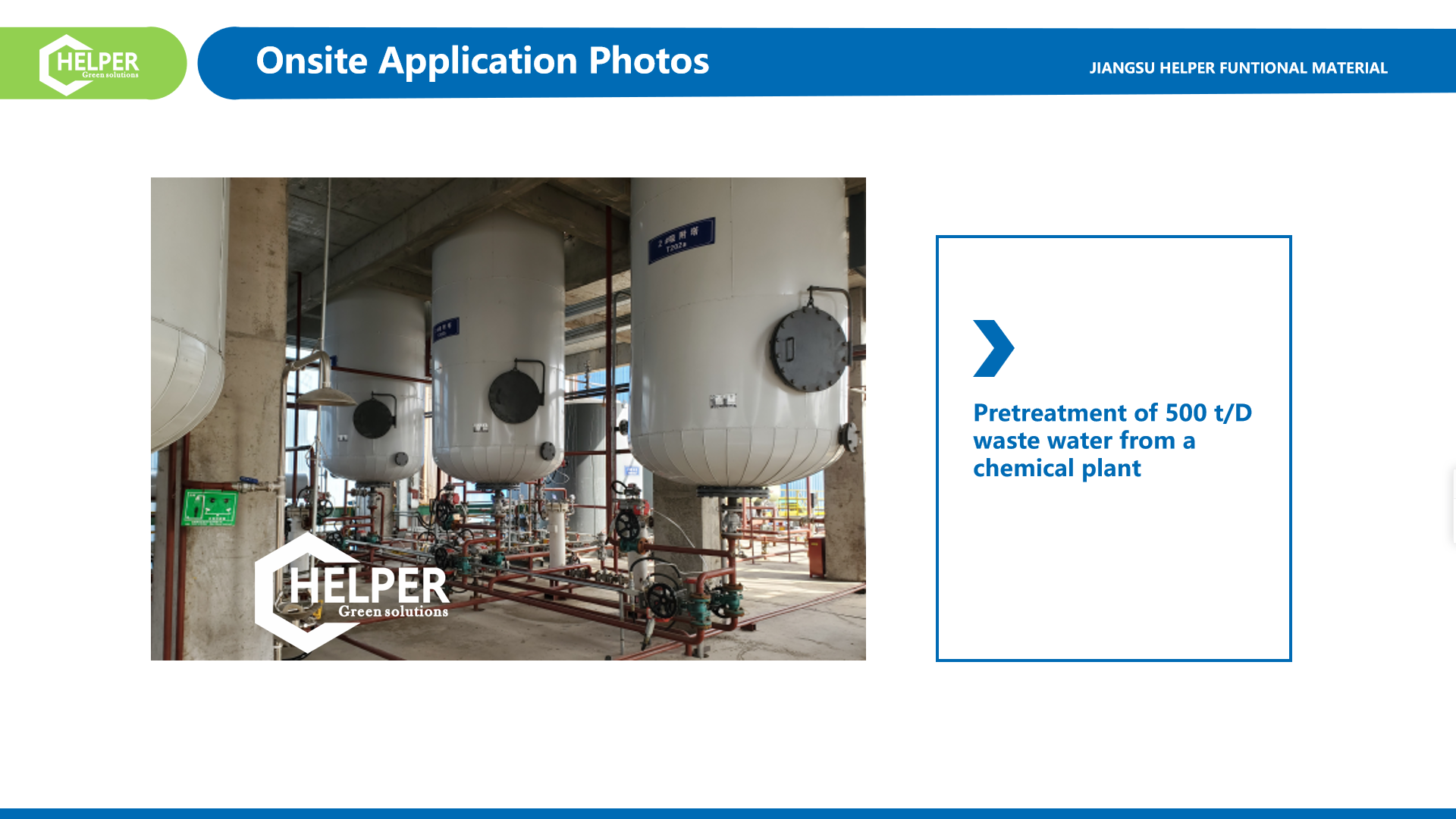

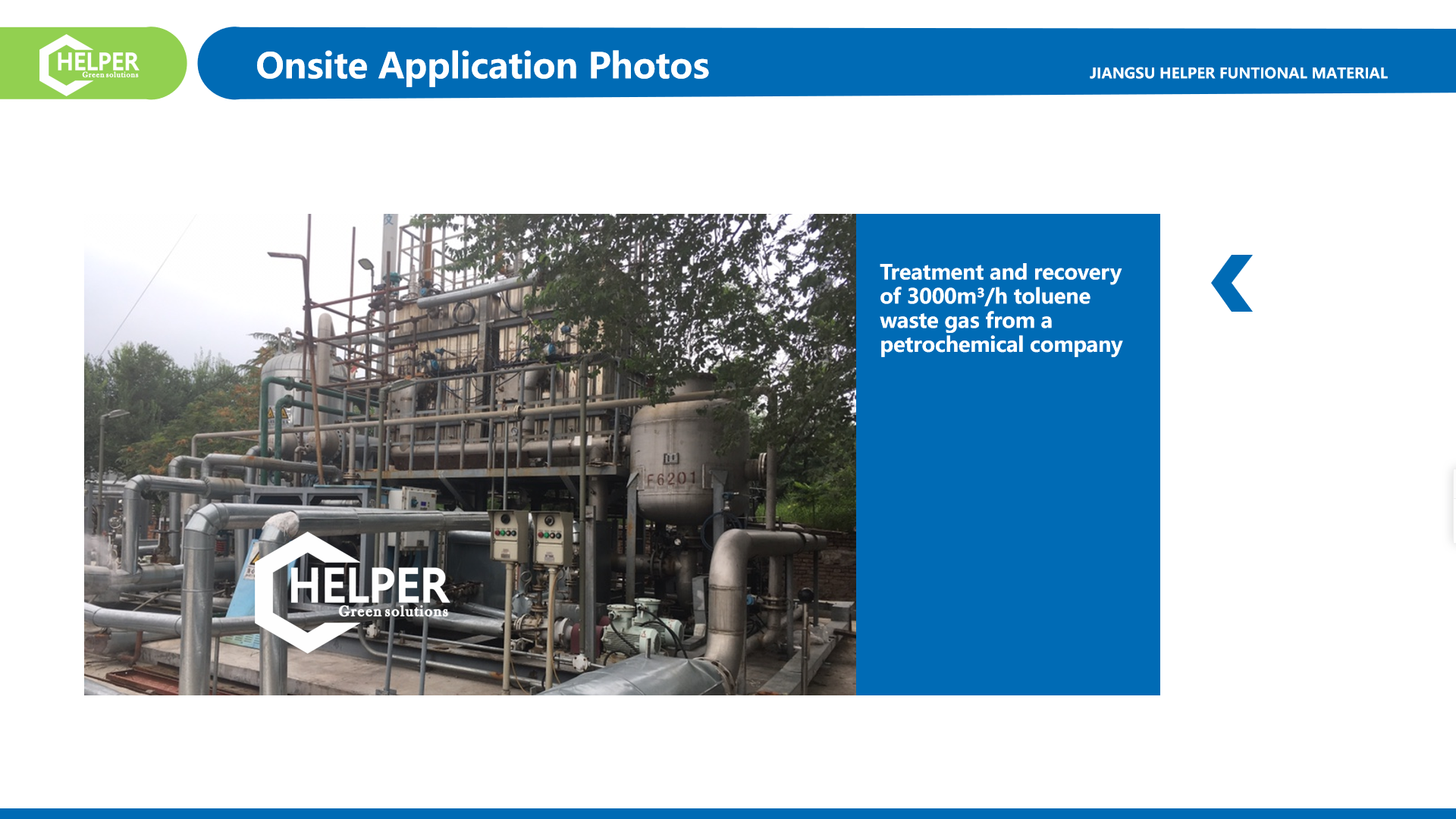

JIANGSU HAIPU FUNCTIONAL MATERIAL CO., LTD

LOCATED in the garden style SIP of Suzhou, as a high-tech enterprise, FOCUSING on the R & D of high-performance adsorbents, catalysts and practical applications. COMMITTED to providing intl leading products, technologies and integrated solutions for various industries, such as environmental protection, new energy, chemical and pharmaceutical industries. RECOGNIZED by customers from all walks of life and governments at all levels. The INTEGRATED SOLUTIONS of water waste, gas waste and acid waste of Haipu have been established dozens of demonstration applications in leading enterprises of petrochemical, agrochemical, pharmaceutical and electroplating industries. AWARDED the National High-tech Enterprise twice in a row. The technical team with Dr. Cai as its core won the 7th SIP Leading Talents Award in 2013, the Gusu Leading Talents Award in 2015 and the 9th SIP Leading Talents Award in 2015. GUIDED by market demand, DRIVEN by technological innovation, HELD by high end talents, Haipu is determined to be a leading role in the environmental protection and green chemistry, and create a well-know high tech enterprise of the world. Haipu will be appreciated to work with you to create the green world.