- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MTED

-

Model Number:

-

RZFD-330

-

Voltage:

-

380v

-

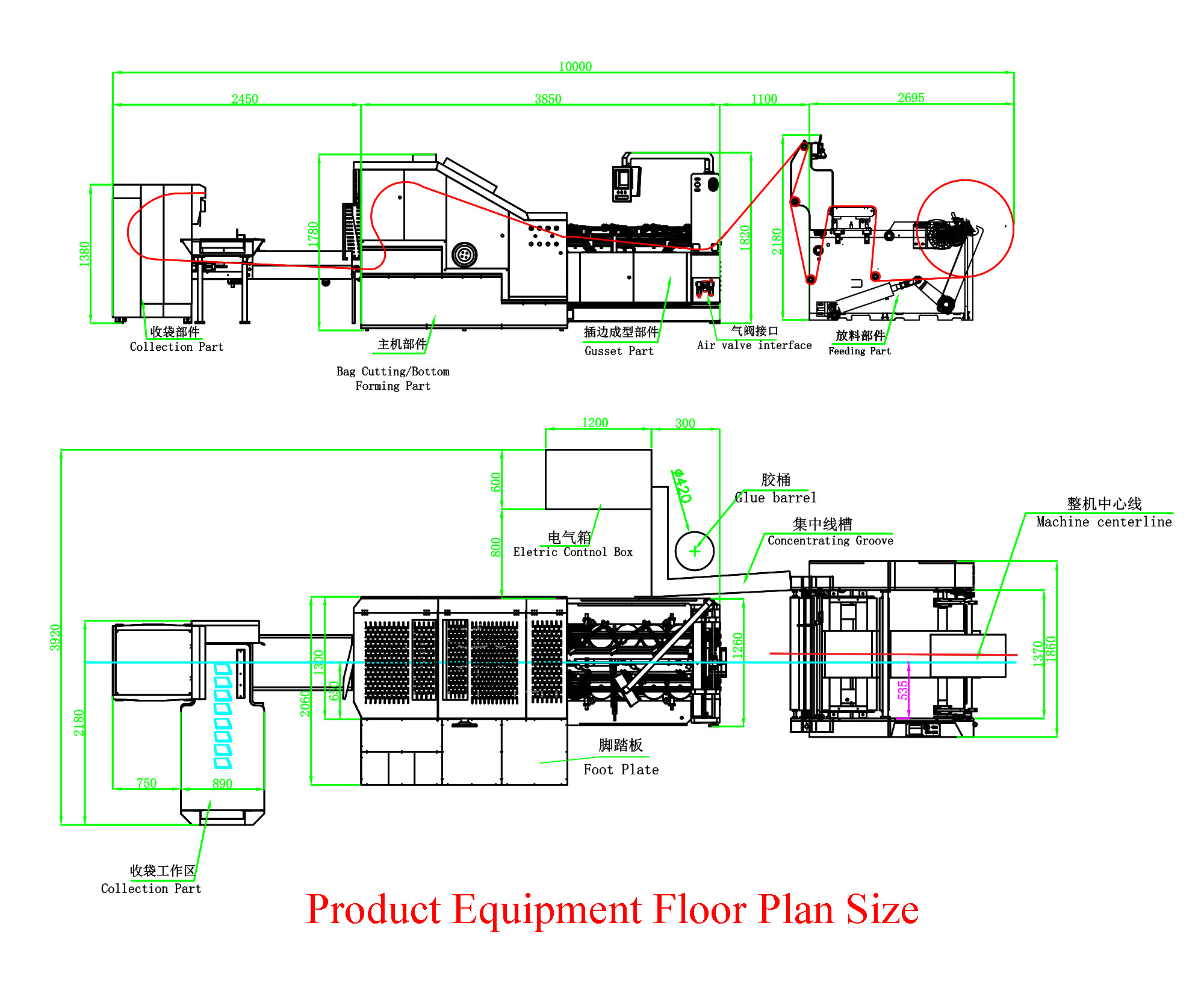

Dimension(L*W*H):

-

9200x3700x2000mm

-

Weight:

-

7200 KG

-

Max Speed:

-

30-180pcs/min

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Paper Bag Length:

-

270-530mm

-

Paper bag width:

-

120-330mm

-

Paper bag bottom width:

-

70-180mm

-

Paper thickness:

-

60-150g/m2

-

Machine Speed:

-

30-220pcs/min

-

Paper bag speed:

-

30-180 pcs/min

-

Paper roll width:

-

380-1050mm

-

Roll paper diameter:

-

1300mm

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Most type paper bags

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MTED

-

Model Number:

-

RZFD-330

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

9200x3700x2000mm

-

Weight:

-

7200 KG

-

Max Speed:

-

30-180pcs/min

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Paper Bag Length:

-

270-530mm

-

Paper bag width:

-

120-330mm

-

Paper bag bottom width:

-

70-180mm

-

Paper thickness:

-

60-150g/m2

-

Machine Speed:

-

30-220pcs/min

-

Paper bag speed:

-

30-180 pcs/min

-

Paper roll width:

-

380-1050mm

-

Roll paper diameter:

-

1300mm

Enterprise Exhibitor Information

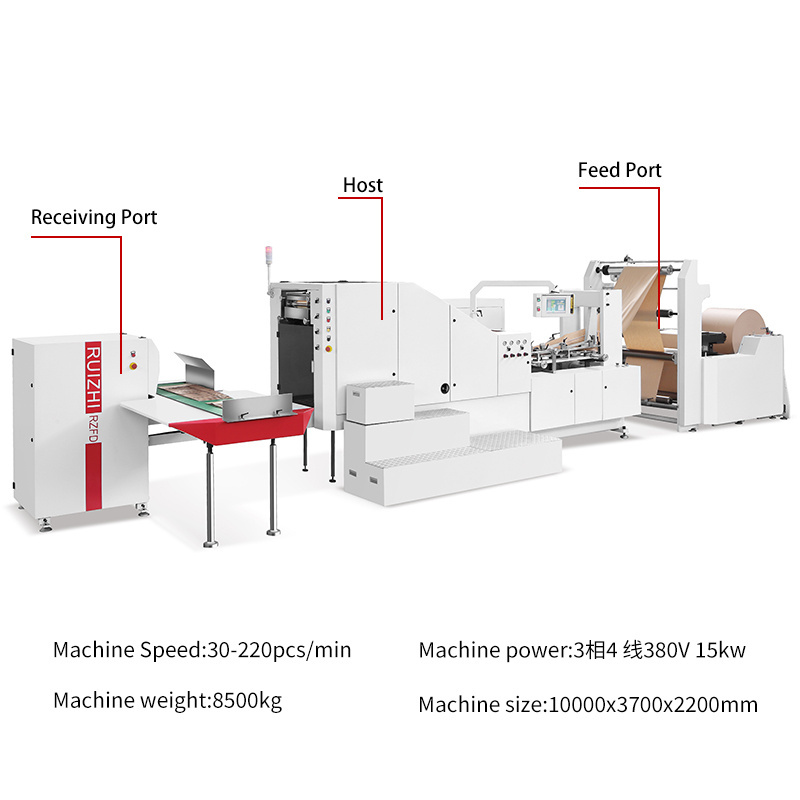

Product Paramenters

Mechanical parameters

|

Model

|

RZFD-330

|

|

Cutting length

|

270-530mm

|

|

Paper bag width

|

120-330mm

|

|

Paper bag bottom width

|

70-180mm

|

|

Paper thickness

|

60-140g/m2

|

|

Paper bag speed

|

30-180 pcs/min

|

|

Paper roll Maximum width

|

1050mm

|

|

Roll paper diameter

|

1200mm

|

|

Machine power

|

3phase 4line 380V 15kw

|

|

Machine weight

|

7200 kg

|

|

Machine size(mm)

|

9200x3700x2000

|

Main Electrical Components List

|

Control System

|

|

|

|

|||

|

Name

|

QTY

|

Original

|

Brand

|

|||

|

PC Program Controller

|

1

|

Germany

|

REXROTH

|

|||

|

Human computer touch screen interface

|

1

|

Schneider

|

FRANCE

|

|||

|

Servo Motor

|

1

|

Germany

|

REXROTH

|

|||

|

Servo Driver

|

1

|

Germany

|

REXROTH

|

|||

|

Traction Servo Motor

|

2

|

Taiwan

|

DELTA

|

|||

|

Servo Driver

|

2

|

Taiwan

|

DELTA

|

|||

|

Motor Frequency Converter

|

1

|

Switzerland

|

ABB

|

|||

|

Positioning Photoelectric Eye

|

1

|

Germany

|

SICK

|

|||

|

Low Voltage Electrical Apparatus

|

1

|

USA

|

EATON

|

|||

|

Button&Junction Box

|

1

|

Germany

|

|

|||

|

Photoelectric Sensor

|

1

|

Switerland

|

Baumer

|

|||

|

Deviation correction and tension control system

|

|

|

|

|||

|

EPC Controller

|

1

|

Italy

|

SELECTRA

|

|||

|

Servo EPC Motor

|

1

|

Italy

|

SELECTRA

|

|||

|

Ultrasonic Sensor

|

1

|

Italy

|

SELECTRA

|

|||

|

Magnetic Powder Brake

|

1

|

China

|

WEIZHENG

|

|||

|

Transmission

|

|

|

|

|||

|

Synchronous Belt

|

1

|

China

|

BELDI

|

|||

|

Synchronous Wheel

|

1

|

China

|

MTED

|

|||

|

Bearing

|

1

|

Germany

|

FALA

|

|||

|

Guide Roller

|

1

|

China

|

BAIXIAO

|

|||

|

Gear

|

1

|

China

|

MTED

|

|||

|

Roll Pneumatic Shaft

|

1

|

China

|

|

|||

|

Finished Bag Conveyor belt

|

1

|

Switzerland

|

|

|||

|

Glue position

|

|

|

|

|||

|

Bottom Glue(Paste bottom white latex)

|

1

|

China

|

MTED

|

|||

|

The center of the water spraying gun

(dense adjust Glue gun )

|

1

|

China

|

MTED

|

|||

|

Water White latex

|

1

|

China

|

MTED

|

|||

Products Description

Properties and Uses

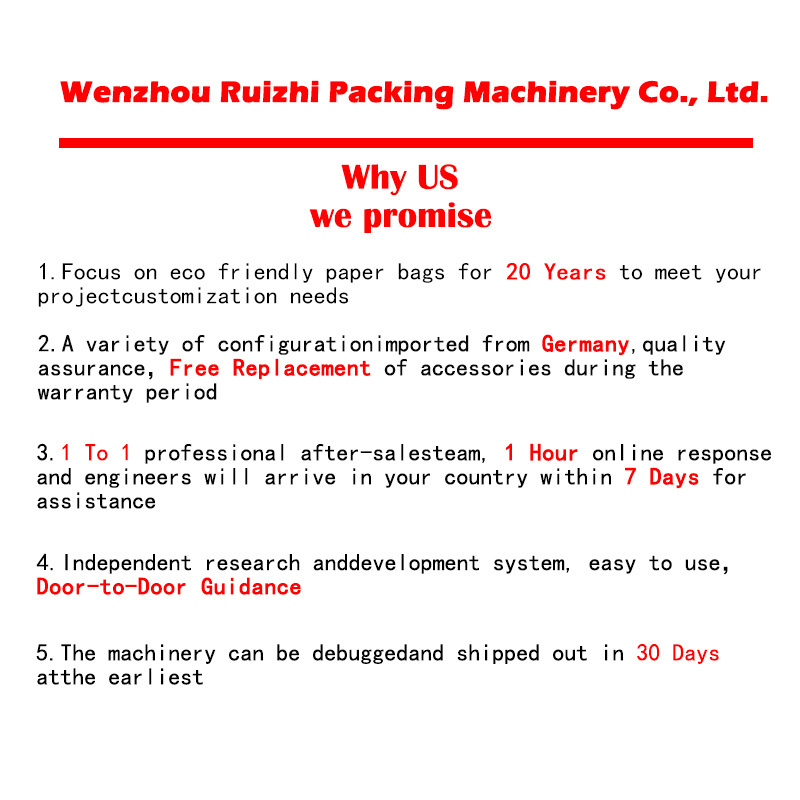

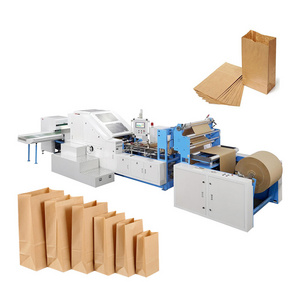

Rolling feed square bottom paper bag making machine, it uses paper roll in blank or printed as raw material. consists of automatic centre forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time,The machine is more convenient, more efficient, more stable, can produce a variety of different paper bags, leisure food bags, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

Main features

1.Use France SCHNEIDER touch screen human-computer interface, making the machineeasy to operate and control.

2.Adopt Germany original LENZE PC control, integrated with optical fiber. Thus ensurestable and high speed running.

3.Adopt Germany original LENZE servo motor and German original SICK photoelectriceye correction, tracking printing bag accurately.

4.Raw material loading adopts hydraulic auto-lifting structure. Unwind unit adopts autotension control.

5.Raw material unwinding EPC adopts Italy SELECTRA, reducing material alignment time.

Production Flow Chart

Enterprise Advantage

We will send technician to your factory to install the machine, and teach your workers to use it

Exhibition

Product packaging

FAQ

Q: Are you a factory or trading company?

A:We are a factory, established in 2003, with a professional team to solve various problems of environmentally friendly paper bags for you

Q: How does your factory do regarding quality control?

A: We have a professional QC department in charge of products' quality.

Q: How long is the warranty period?

A: 12 months calculated from the date of shipment from our factory.During warranty period, except the artificial factor, the spares are free to replace,beyond the warranty time, the buyer needs to pay the spare charge and shipping cost.

Q: How to install the machine?

A: We will send technician to your factory to install the machine, and teach your workers to use it. You pay all related costs, including visa charge, double-way tickets, hotel, meals, and technician salary.

Q: Where is your factory located? How can we visit there?

A: Our factory is located in WENZHOU city,. We will provide transporation service during your visit at our factory.

Q: What information should I let you know if I want to get a quotation?

A: First, Paper raw material: Reel paper or Sheet Paper. Second, sizes of the paper bag, thickness of paper.

Send sample bag picture if available. Then we will recommend the right machine to you!

Hot Searches