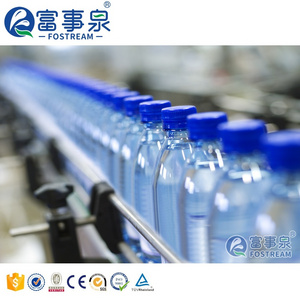

(1)water filling line/liquid filling line includes: Washing-filling-capping 3 in 1 machine, lamp inspection, label shrinking

machine, inkjet printer, hot shrink film packer and conveyors. It is a full automatic production line.

(2)The water filling line is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

(3)The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

(4)The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machinery of the same specifications.

(5)The advanced OMRON programmed controller (PLC) is adopted to control the machine to run automatically while a transducer is used in the bottle -entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably.

(6)It is convenient to operate with higher automation because every part of the machine is inspected to run with photo electricity, On the bases, the filling parts of the machine can be changed into filling methods of lower vacuum.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220V/380V 50HZ 3P

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Grandee

-

Dimension(L*W*H):

-

2900X1700X2300MM

-

Weight:

-

950 KG

-

Product name:

-

5L 7L 10L Water Bottling Machine

-

Filling material:

-

Mineral or pure water

-

Function:

-

Washing Filling Capping Machine

-

Usage:

-

Beverage Packaging System

-

Processing Types:

-

Flow filling valves

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

SUS304/316

-

Capacity:

-

300BPH for 5000ml bottle

-

Washing pressure:

-

0.3-0.7MPa

-

Bottle washing medium:

-

sterile water

Quick Details

-

Machinery Capacity:

-

400BPH, 300BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Water

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220V/380V 50HZ 3P

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Grandee

-

Dimension(L*W*H):

-

2900X1700X2300MM

-

Weight:

-

950 KG

-

Product name:

-

5L 7L 10L Water Bottling Machine

-

Filling material:

-

Mineral or pure water

-

Function:

-

Washing Filling Capping Machine

-

Usage:

-

Beverage Packaging System

-

Processing Types:

-

Flow filling valves

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

SUS304/316

-

Capacity:

-

300BPH for 5000ml bottle

-

Washing pressure:

-

0.3-0.7MPa

-

Bottle washing medium:

-

sterile water

GRANDEE MACHINE

is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

Products Description

5L 10L 12L Plastic Bottle Mineral Pure Water Filling Production Machine

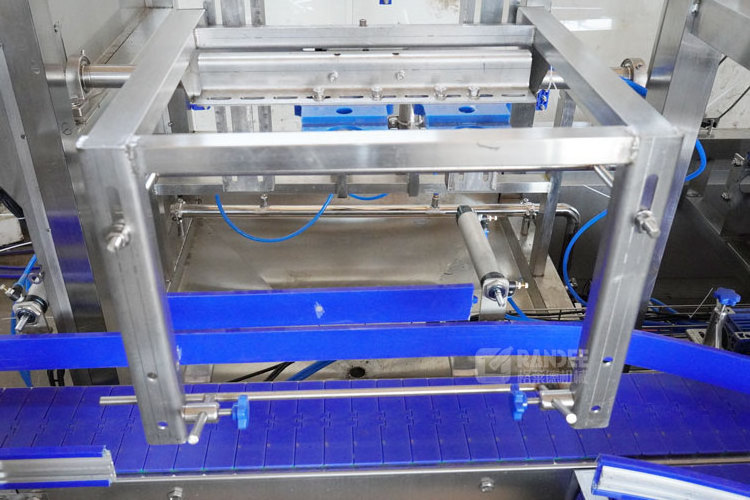

Washing part

The grippers take the bottles from the inlet star-wheel while they are still driven by the star-wheel, thus guaranteeing a safe

grip. After the gripping, the bottle is turned upside down with 180 degree and cantred above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again

grip. After the gripping, the bottle is turned upside down with 180 degree and cantred above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again

Filling part

Long tube filling type with 2 times filling process to make sure perfect filling level

Liquid tank, filling valves, controlling rings, upgrading cylinder.

Hig h speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made

Liquid tank, filling valves, controlling rings, upgrading cylinder.

Hig h speed and mass flow filling valve ensures the high filling speed and exact fluid level. Parts contacting liquid are all made

of excellent stainless steel or food grade engineering plastic.

Capping part

Rotative capping turret, suitable to the application of screw plastic caps on PET bottles The fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating the capping heads.

The heads are raised and lowered by the action of a follower that is riding on a shaped cam.

The heads are raised and lowered by the action of a follower that is riding on a shaped cam.

Backward / rotation electrical motor

This is backward motor of washing machine, the advantage is more stable than air cylinder structure overturning bottle. Sensor

controlled the bottle stop and start.

controlled the bottle stop and start.

Electrical control cabinet

HMI and PLC Mitsubishi brand, Frequency converter control filling process.

Main technical parameter

|

Model

|

XGF

2-2-1

|

XGF

4-4-1

|

XGF

6-6-1

|

XGF

8-8-1

|

XGF

10-10-1

|

XGF

32-32-10

|

XGF

40-40-12

|

||||||

|

Capacity(5l/BPH)

|

300-400

|

500-600

|

700-800

|

800-1000

|

1000-1200

|

14000

|

16000

|

||||||

|

Suitable bottle shape and size

|

Both round of square bottle, 3l-15l bottle

|

|

|

|

|

|

|

||||||

|

Compressed air pressure

|

0.3-0.7MPa

|

|

|

|

|

|

|

||||||

|

Bottle washing medium

|

Sterile water

|

|

|

|

|

|

|

||||||

|

Washing pressure

|

0.25MPa

|

|

|

|

|

|

|

||||||

|

Main motor

|

1.5

|

2.2

|

3.5

|

4.5

|

5.5

|

5.5

|

7.5

|

||||||

|

Dimension(mm)

|

2900*1700*2300

|

3200*1700*2300

|

3800*1700*2300

|

4200*1700*2300

|

4500*1800*2300

|

2970*2260*2700

|

3780*2800*2700

|

||||||

|

Weight(KG)

|

950

|

1200

|

1500

|

2000

|

2500

|

6500

|

8500

|

||||||

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

CONTACTOR

|

Siemens

|

Germany

|

|

TOUCH SCREEN

|

Siemens

|

Germany

|

|

INVERTER

|

Siemens

|

Germany

|

|

MOTOR

|

ABB

|

SWISS

|

|

PNEUMATIC PARTS

|

FESTO

|

GERMANY

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

For more information, please feel free to contact us to

send an inquiry

!

Turnkey Solution

1.RO system

This RO system is very important in the whole water project, we prefer you supply water analysis report from your local inspection department. This RO system we can make to match up with your water filling machine from capacity from 500L/Hr to 50000L/hr.

This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised.We use GNP or CNP water pump, USA DOW or HYDRANAUTICS membrane, etc

This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised.We use GNP or CNP water pump, USA DOW or HYDRANAUTICS membrane, etc

3. Automatic OPP hot glue labeling machine:

Capacity: 100-350bottles/min can be chosen Label material: PVC PET OPS, etc

Bottle material: PET PE PP Glass Bottle Diameter: 28 ~ 120mm

Bottle Height: 15~320mm Bottle shape: round, square, ellipse, rectangular

Label length: 30~250mm(max) Label thickness: 0.03~0.13mm

Bottle material: PET PE PP Glass Bottle Diameter: 28 ~ 120mm

Bottle Height: 15~320mm Bottle shape: round, square, ellipse, rectangular

Label length: 30~250mm(max) Label thickness: 0.03~0.13mm

Recommend Products

Turkey Project - Carbonated Drink/Water/Juice Production Line

Hot Searches