- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

dongying

-

Model Number:

-

N35-N52

-

Delivery Time:

-

7-15 days

-

Magnetic direction:

-

Thickness (axial)

-

Operation temperature:

-

Below 80°

-

Processing services:

-

Bending, welding, uncoiling, cutting, punching, forming

Quick Details

-

Tolerance:

-

±5%

-

Grade:

-

NdFeB magnet

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

dongying

-

Model Number:

-

N35-N52

-

Delivery Time:

-

7-15 days

-

Magnetic direction:

-

Thickness (axial)

-

Operation temperature:

-

Below 80°

-

Processing services:

-

Bending, welding, uncoiling, cutting, punching, forming

|

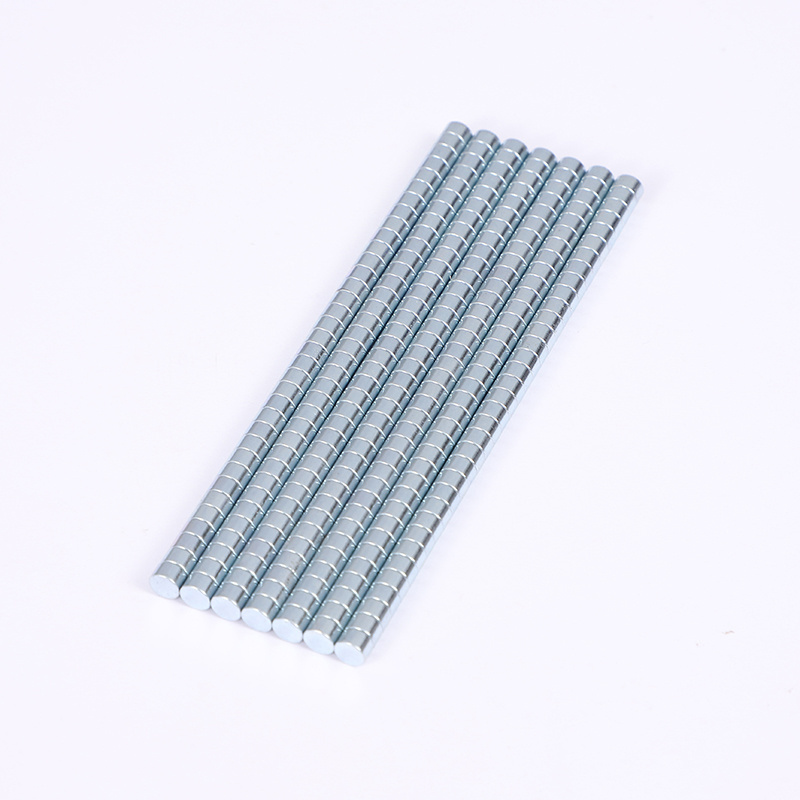

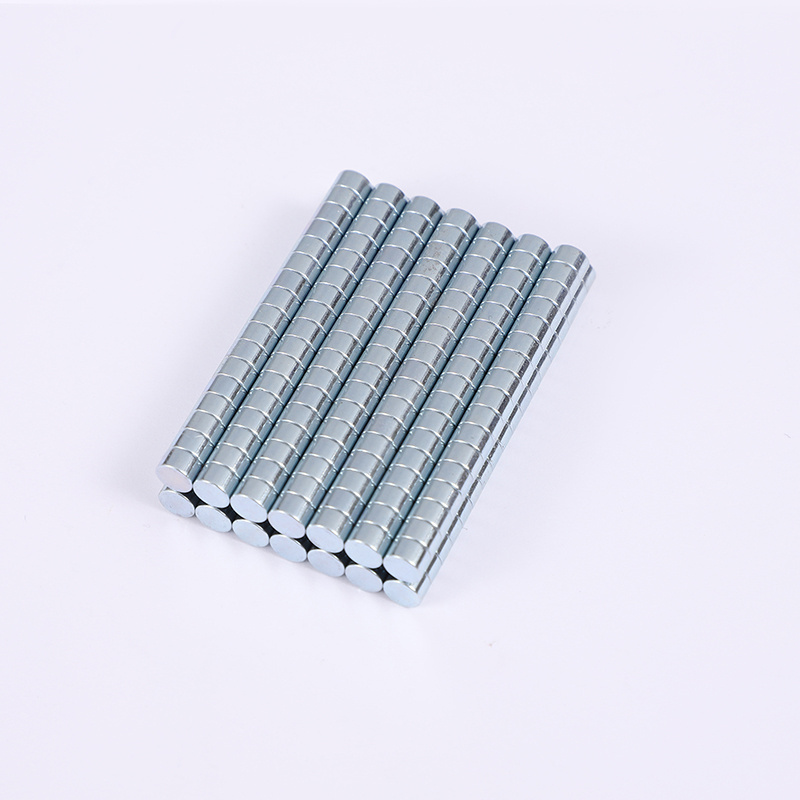

Product Name

|

Magnet

|

|

Material

|

N35-N52, Temperature resistant series M, H, SH, UH, EK, AH

|

|

Demension

|

Customized size

|

|

Coating

|

Zinc

|

|

Letter

|

N

|

M

|

H

|

SH

|

UH

|

EH

|

AH

|

|

Temperature

|

80℃

|

100℃

|

120℃

|

150℃

|

180℃

|

200℃

|

250℃

|

NdFeB magnet

The third-generation rare earth permanent magnet NdFeB is the most powerful permanent magnet among modern magnets. Not only does it have high remanence, high coercivity, high magnetic energy product, and high cost-effectiveness, but it is also easy to machine into various sizes. Currently, it has been widely applied in various fields. Especially suitable for developing high-performance, miniaturized, and lightweight alternative products.

|

Cladding Material

|

Thickness

|

Salt

Spray Test

|

|

Zinc

|

7-15 μm

|

12 hours

|

|

NiCuNi

|

15-21 μm

|

24 -72 hours

|

|

Black Nickel

|

20-28 μm

|

24hours

|

|

Epoxy

|

16-23 μm

|

48 hours

|

|

Gold

|

16-23 μm

|

36 hours

|

|

Sliver

|

16-23 μm

|

24 hours

|

Magnetic direction

1.What material and performance?

2. Dimensions and tolerances?

3. Do you want to magnetize? What is the method of magnetization, axial? Radial?

4. What is the maximum temperature in the working environment of the magnet?

5. Order quantity?

6. Surface treatment? Galvanized, nickel plated?

7. If special treatment is required, please let us know.

We accept customized services:

1) Shape and size (processed according to design drawings)

2) Material (magnetic strength requirement)

3) Plating (surface treatment requirements for appearance)

Magnetization direction (which magnetic surface is required)

Temperature

When selecting a magnet, customers should choose the appropriate magnet brand based on its working temperature. If the working temperature is higher than the temperature borne by the magnet brand, the magnet will slowly demagnetize until it becomes demagnetized. Please make sure to confirm the working temperature and the brand suitable for your own use before ordering.

Environment

Magnets should be stored in a dry, constant temperature environment, separated and wrapped with plastic, wood chips, cardboard, foam, etc. Keep away from iron objects and easily magnetized items, such as monitors, bank cards, computers, televisions, mobile phones, etc.

Handling and stacking

The magnet material is hard, brittle, and has a strong magnetic field. It should be handled with care (especially large specifications and thin sheets). When the strong magnet itself or when it is attracted or separated from other iron objects, it should be handled with caution and not be impacted. Otherwise, it is easy to cause collisions and damage magnets or pinch fingers. Because magnets belong to non-metallic alloy materials with a density between 7.5, they have heavy and brittle properties. So be particularly careful when handling to avoid magnetic breakage. When storing, the environment should also be kept dry, not directly stacked on the ground, preferably padded with thick cardboard or placed on shelves.

Security

This product has small magnets that must be kept away from children to avoid swallowing. Place the magnets in the nose or mouth, as swallowed magnets may stick together in the intestines, causing serious or fatal injury. If swallowed or inhaled, seek medical attention immediately.

Q: Could I have prices of your products?

A:Welcome. Please feel free to send us an email here. You will get our reply in 24 hours

Q:

Are you trading company or manufacturer?

A:

We are a magnet manufacture,which is in a integration of industry and trade and raw materials productions.

Q:

What's the lead time for regular order?

A:

7-15 days for order quantity lower than 1000pcs

Q:

Can I get a discount?

A:

Yes, for the order quantity more than 1000 pcs, please contact us to get the best price.

Q:

Do you inspect the finished products?

A:

Yes, each step of production and finished products will be came out inspection by QC department before shipping.

Hot Searches