- Product Details

- {{item.text}}

Quick Details

-

MF:

-

O2Si

-

EINECS No.:

-

215-684-8

-

Place of Origin:

-

Hubei, China

-

Appearance:

-

White Nano-Scaled Powder

-

Application:

-

Printing & Ink; Coating; Sealants; Rubber

-

Brand Name:

-

HIFULL

-

Model Number:

-

HL-200

-

Product name:

-

Hydrophilic fumed silica HL-200 nano particle silicon dioxide

-

Primary particle size:

-

5-50 nm

-

Country of Origin:

-

China

-

HS code:

-

28112200

-

Advantage 01:

-

Factory direct sell

-

purity:

-

≥99.8%

-

Advantage 02:

-

ISO 9001, REACH certificates

-

Type:

-

nano materials

-

One bag dimension:

-

110cm*55cm*25cm

-

sample:

-

free provided

Quick Details

-

CAS No.:

-

112945-52-5

-

Purity:

-

99.8%

-

Other Names:

-

Silicon Dioxide

-

MF:

-

O2Si

-

EINECS No.:

-

215-684-8

-

Place of Origin:

-

Hubei, China

-

Appearance:

-

White Nano-Scaled Powder

-

Application:

-

Printing & Ink; Coating; Sealants; Rubber

-

Brand Name:

-

HIFULL

-

Model Number:

-

HL-200

-

Product name:

-

Hydrophilic fumed silica HL-200 nano particle silicon dioxide

-

Primary particle size:

-

5-50 nm

-

Country of Origin:

-

China

-

HS code:

-

28112200

-

Advantage 01:

-

Factory direct sell

-

purity:

-

≥99.8%

-

Advantage 02:

-

ISO 9001, REACH certificates

-

Type:

-

nano materials

-

One bag dimension:

-

110cm*55cm*25cm

-

sample:

-

free provided

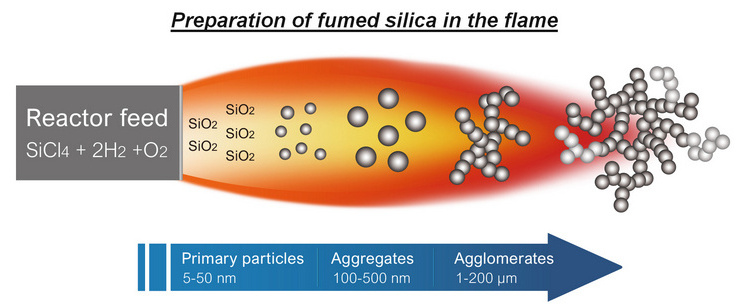

About Fumed Silica

Fumed silica (pyrogenic silicon dioxide)

is produced in the flame. It is one kind of pure amorphous white inorganic powder that has a high specific surface area,

nanoscale primary particle size of 7-40 nm

, which is divided into hydrophilic type and hydrophobic type, according to whether it can be dispersed in water or not.

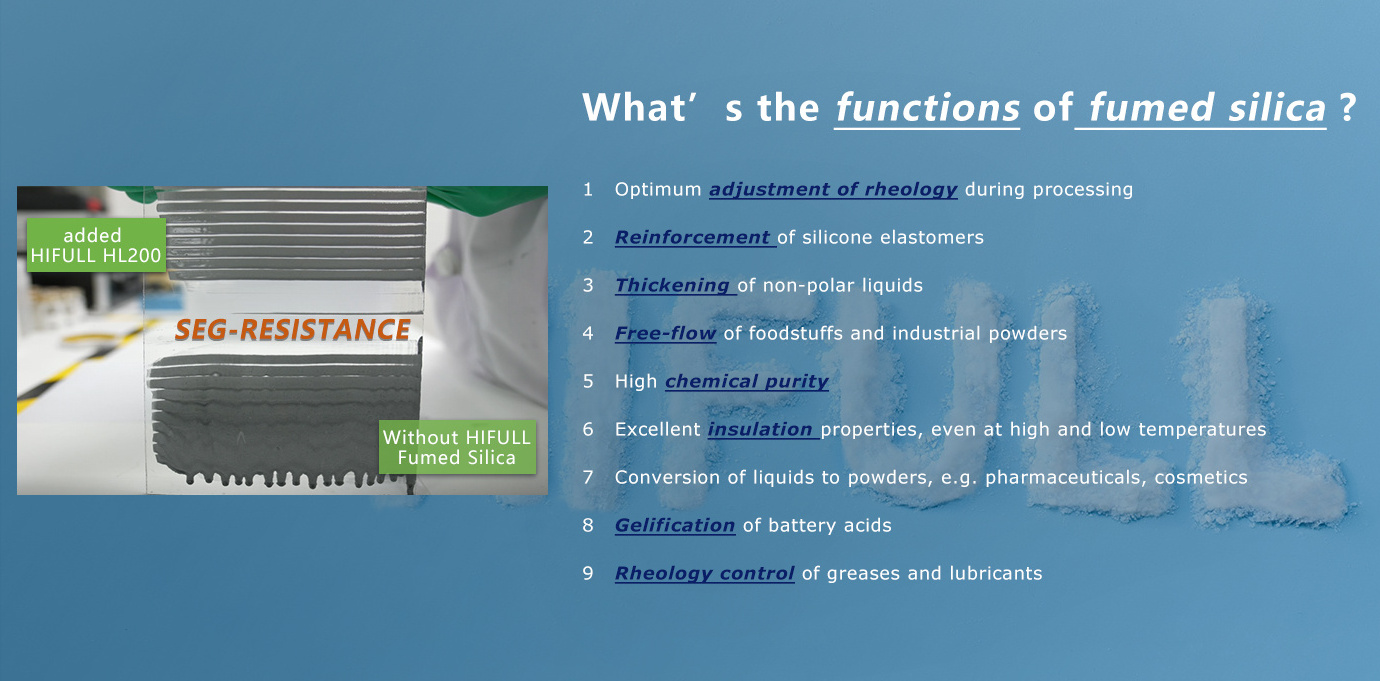

Product Application

Applications of HL 200

Coatings & P

aintings

HTV & RTV Silicone Rubber

Silicon Elastomers

UPR & Thin Film

Adhesives & Sealants

Printing ink

UPR & Thin Film

Adhesives & Sealants

Printing ink

Cosmetics

1.Coatings & Paintings → Improve Thixotropic & Anti-settling properties & Increased scratch resistance

2.Adhesives & Sealants → adjustment of rheology during processing & thickening effect

3.HTV&RTV Silicon Rubbers → reinforcement of silicone elastomers & thickening effect

4.Thin Film & UPR → reinforce physical strength & tensile strength

5.Printing Ink → anti-settling & thickening

6.Fertilizer & Pesticide → thickening & anti-settling for liquid system product ;

→ anti-caking & free flow aid for powder products

7.Cosmetics → Improve thickening & anti-caking & anti-settling perofrmance

2.Adhesives & Sealants → adjustment of rheology during processing & thickening effect

3.HTV&RTV Silicon Rubbers → reinforcement of silicone elastomers & thickening effect

4.Thin Film & UPR → reinforce physical strength & tensile strength

5.Printing Ink → anti-settling & thickening

6.Fertilizer & Pesticide → thickening & anti-settling for liquid system product ;

→ anti-caking & free flow aid for powder products

7.Cosmetics → Improve thickening & anti-caking & anti-settling perofrmance

|

Application

|

|

Main Functions

|

Recommend Grade

|

Suggested Usage(%)

|

|

|

Silicone rubber

|

HTV silicone rubber

|

reinforcing, transparent

|

HL-200, HL-300, HL-380, HB-132

|

0.5 - 3

|

|

|

|

Silicone rubber insulator

|

reinforcing,insulate

|

HL-150,HL-200,HB-139

|

0.5 - 3

|

|

|

|

RTV silicone rubber

|

rheology control

|

HL-150,HL-200,HB Series

|

0.5 - 3

|

|

|

Powder coating

|

Corona discharge

|

free flowing, anti-caking, dispersion, charge control

|

HB-630,HB-151,HL-200,HL-300,HL-380

|

0.5 - 3

|

|

|

Varnish

|

PU,Acrylic acid, epoxy-polyester, amino

|

|

HB-630,HB-151,HL-200,HL-300

|

0.5 - 3

|

|

|

Liquid coating

|

industrial paint and marine paint

|

anti-sagging, anti-settling, thickening, thixotropy,leveling

|

HB-139,HB-151,HB-630

|

0.5 - 3

|

|

|

|

acrylic acid, polyester, nitro

|

anti-sagging, anti-settling, thickening, thixotropy

|

HL-200,HL-300

|

0.5 - 3

|

|

|

|

Epoxy, vinyl polyester, PU

|

anti-sagging, anti-settling, thickening, thixotropy

|

HB-151,HB-139

|

0.5 - 3

|

|

|

Sealant

|

PU

|

thixotropy,anti-sagging, water content control

|

HB-139,HB-151,HL-200

|

3 - 7

|

|

|

Adhesive

|

Epoxy

|

reinforcing, thixotropy, anti-sagging, thickening

|

HB-139,HB-151, HL-200, HL-300

|

1.5 - 3

|

|

|

Composite material

|

|

thixotropy, anti-settling, anti-sagging, thickening

|

HL-200, HL-300, HB-151, HB-139

|

0.5 - 3

|

|

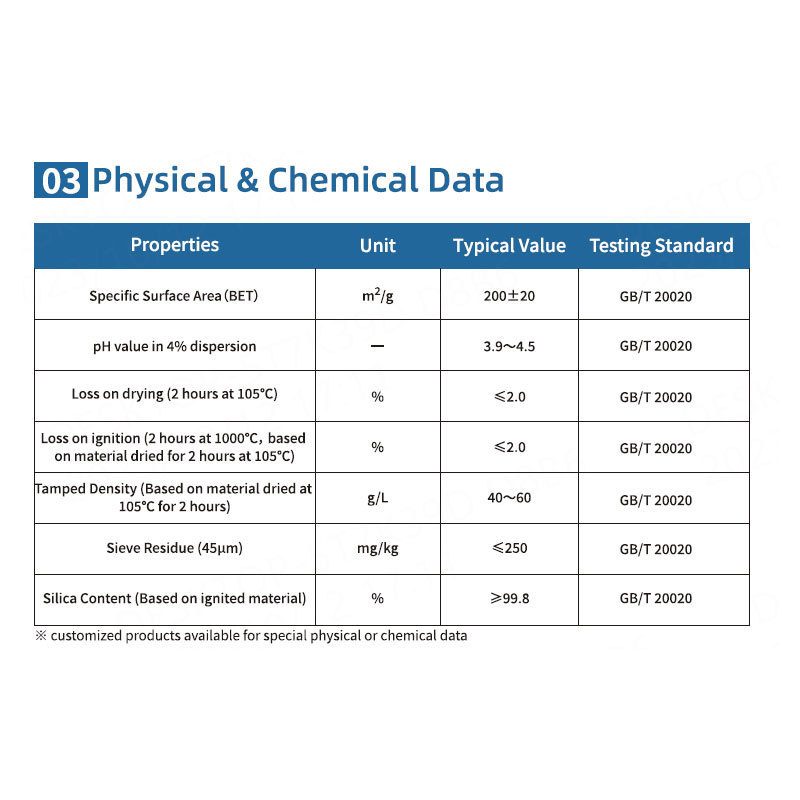

Product Description

|

P

hysical & Chemical Data of HL 200

|

|

|

|

|||

|

Properties

|

Unit

|

Typical Value

|

Testing Standard

|

|||

|

Specific surface area (BET)

|

m

2

/g

|

200±20

|

GB/T 20020

|

|||

|

pH value in 4% dispersion

|

|

3.9~4.5

|

GB/T 20020

|

|||

|

Loss on drying

(2 hour at 105℃)

|

%

|

≤2.0

|

GB/T 20020

|

|||

|

Loss on ignition

(2 hours at 1000°, based on material dried for 2 hours at 105℃)

|

%

|

≤2.0

|

GB/T 20020

|

|||

|

Sieve Residue (45μm)

|

mg/kg

|

≤250

|

GB/T 20020

|

|||

|

Silica content

( Based on ignited material)

|

%

|

≥99.8

|

GB/T 20020

|

|||

|

Tamped Density (Based on material dried at 105℃ for 2 hours)

|

g/L

|

40~60

|

GB/T 20020

|

|||

More products- HIFULL fumed silica

Below table is part of our main product, which includes hydrophilic and hydrophobic grades.

Click the "'Chat Now" button on the right side to know which grade you need!

|

Grade

|

HL-300

|

HL-380

|

HB-139

|

HB-151

|

HB-615

|

HB-630

|

|||||

|

Form

|

white amorphous powder

|

|

|

|

|

|

|||||

|

Surface

area

(m2/g)

|

300±25

|

380±30

|

110±30

|

120±30

|

140±20

|

300±30

|

|||||

|

PH value

|

3.7-4.5

|

3.7-4.5

|

4.0-7.0

|

≥3.7

|

5.0-8.0

|

6.0-9.0

|

|||||

|

Loss on drying

(2h,105℃) % |

≤2.0

|

≤2.5

|

≤0.7

|

≤0.7

|

≤0.7

|

≤0.7

|

|||||

|

Loss on ignition (2h,1000℃) %

|

≤2.5

|

≤2.5

|

≤10

|

≤2.5

|

≤4.0

|

≤5.0

|

|||||

|

silica content (%)

|

≥99.8

|

|

|

|

|

|

|||||

|

Tamped density (g/dm²)

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

|||||

|

Surface treatment

|

No

|

No

|

PDMS

|

DDS

|

HMDS

|

HMDS

|

|||||

Hot Searches