- Product Details

- {{item.text}}

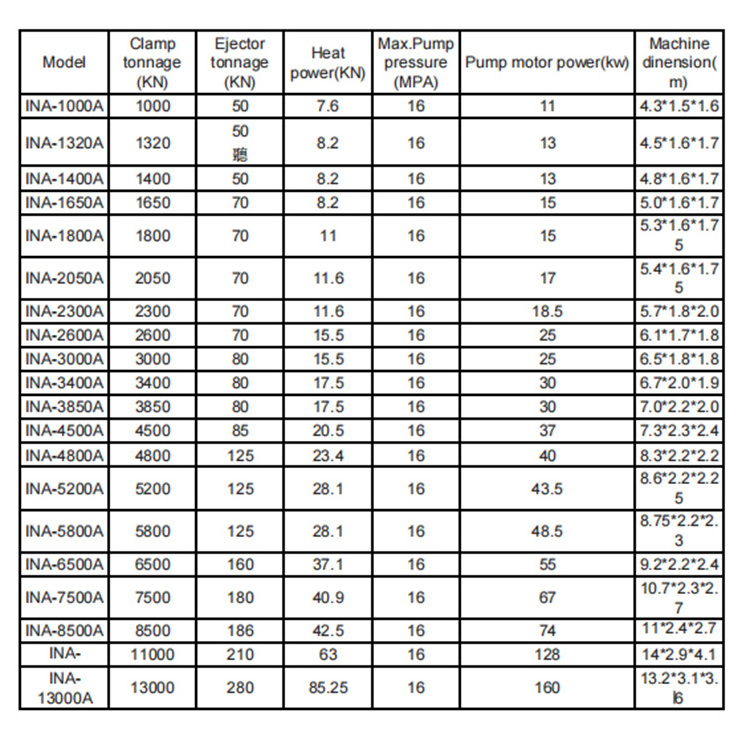

Quick Details

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

460 cm³

-

Injection Rate (g/s):

-

190 g/s

-

Injection Weight (g):

-

600 g

-

Screw diameter (mm):

-

40 mm

-

Weight (KG):

-

6000 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

3840 mm

-

Model Number:

-

INN-1320A

-

Brand Name:

-

INNAWEI

-

Power (kW):

-

28.6 kW

-

Product name:

-

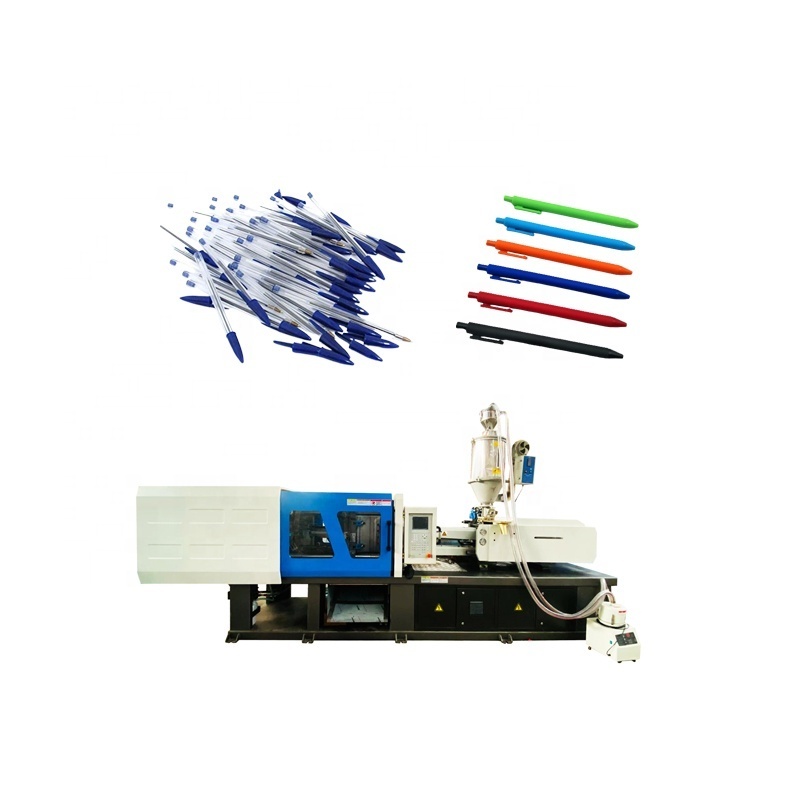

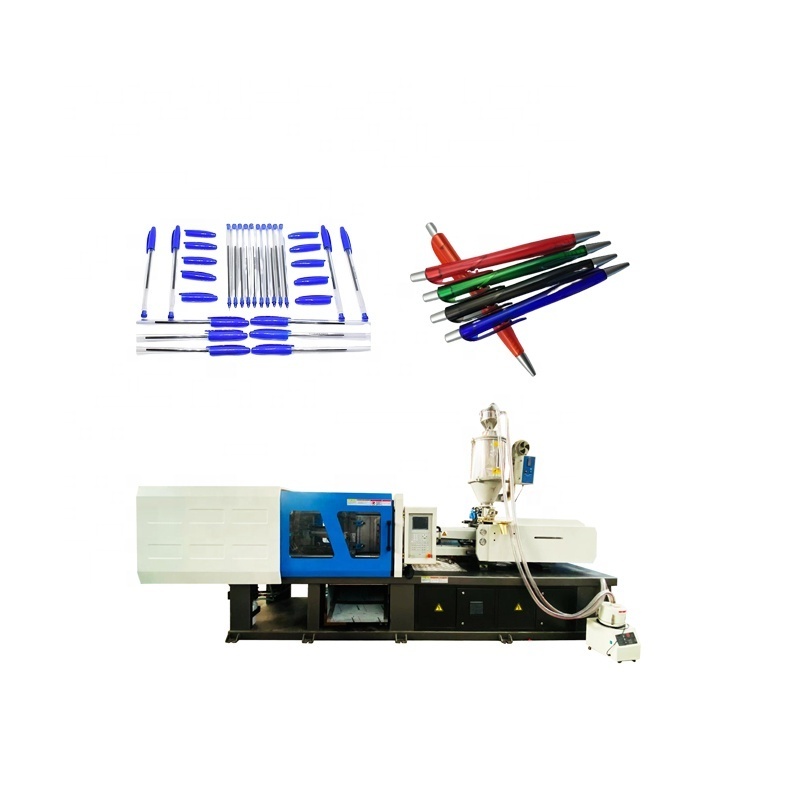

ball pen making machine

-

Name:

-

ball pen moulding machine

-

Oil tank capacity:

-

200L

-

Keyword:

-

ball pen injection molding machine

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

190mm

-

Distance between Tie Bars(Height)(mm):

-

470mm

-

Ejector Stroke(mm):

-

155 mm

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

460 cm³

-

Injection Rate (g/s):

-

190 g/s

-

Injection Weight (g):

-

600 g

-

Screw diameter (mm):

-

40 mm

-

Weight (KG):

-

6000 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

3840 mm

-

Model Number:

-

INN-1320A

-

Brand Name:

-

INNAWEI

-

Power (kW):

-

28.6 kW

-

Product name:

-

ball pen making machine

-

Name:

-

ball pen moulding machine

-

Oil tank capacity:

-

200L

-

Keyword:

-

ball pen injection molding machine

Product Overview

what is Ballpoint Pen Production Line

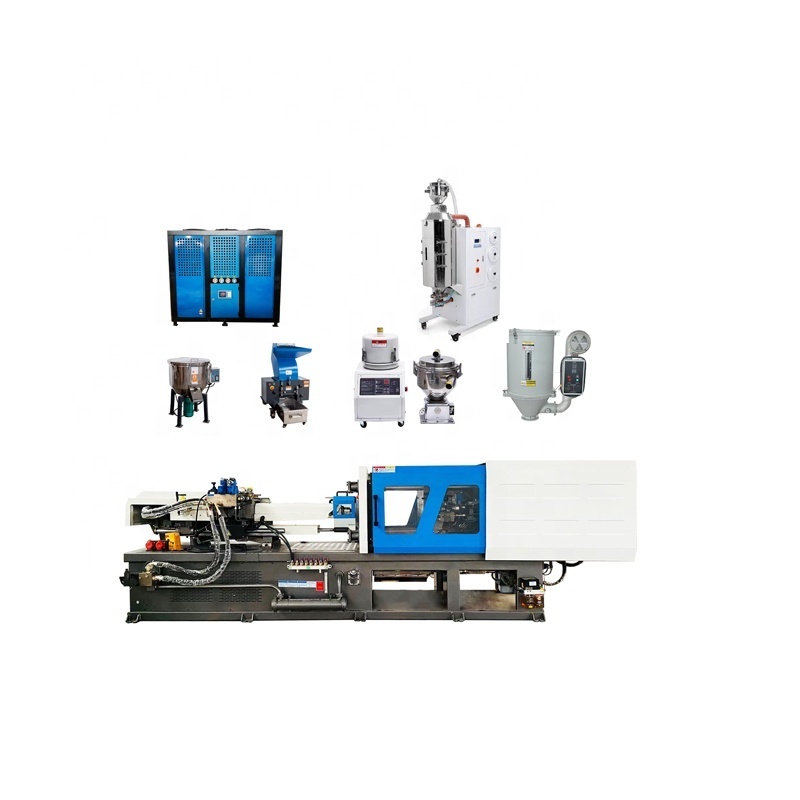

A Ballpoint Pen Production Line is a manufacturing system designed and set up for the mass production of ballpoint pens. It includes a series of machines, equipment, and processes that work together to produce ballpoint pens efficiently and in large quantities. Here's a brief overview of what a typical Ballpoint Pen Production Line might consist of:

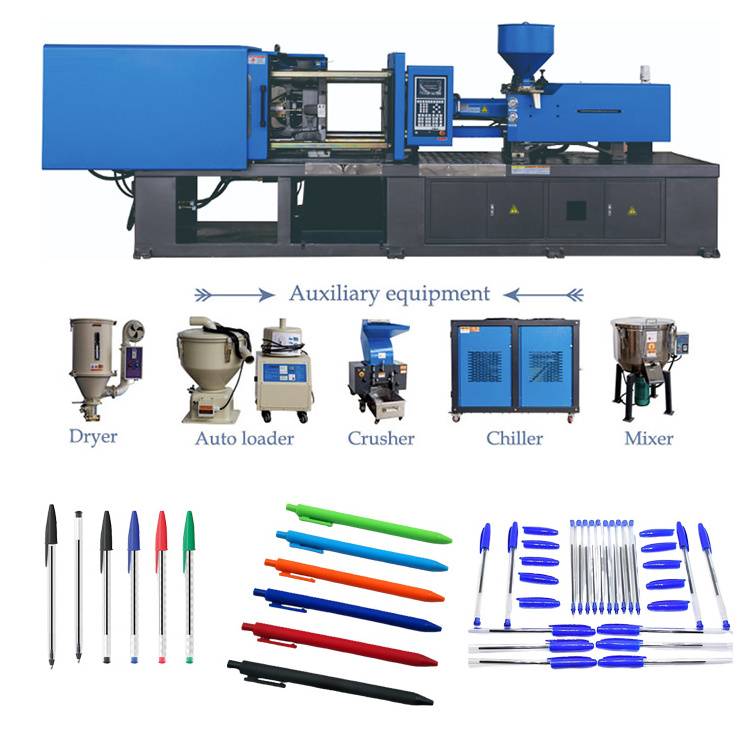

Injection Molding Machine: This machine is used to mold the plastic components of the pen, such as the pen body and cap.

Refill Filling Machine: It fills the pen refills with ink, which is a critical component of ballpoint pens.

Assembly Line: This is where various components of the pen, including the refill, ballpoint mechanism, cap, and body, are assembled together.

The goal of a Ballpoint Pen Production Line is to produce ballpoint pens at a high rate, ensuring consistency in quality and minimizing production costs. These production lines are used by manufacturers to meet the demand for ballpoint pens in the market, whether for office supplies, promotional items, or other purposes.

FEATURES AT A GLANCE

CONTROL SYSTEM

All-digital control system uses dedicated controller, multiple CPU processing division,

a multi-functional automatic fault detection, alarm system, certificates 99 mold of

processing procedures, with remote control interface. System is of high stability and

responsiveness. System uses color LCD, man made interface for easy operation and

with a number of peripheral interfaces.

HYDRAULIC SYSTEM

Advanced hydraulic system design, through proportional control of pressure, flow achieves rapid multi-level pressure, speed switching, the system configuration is reasonable, stable and reliable. The noise is less than 75 dB. The medium and large machine adopts a two-way cartridge inserted valve system to improve the system of flow and speed of response, and

SERVO SYSTEM

After receiving the pressure and flow instruction from computer controller, the servo driver will compare it with the actual

pressure and flow feedback, and rectify the difference the rotating speed of the servo motor. in this way , the control of

injection moulding is not only acurate but also fast, and the repeatability of the products high as well.

pressure and flow feedback, and rectify the difference the rotating speed of the servo motor. in this way , the control of

injection moulding is not only acurate but also fast, and the repeatability of the products high as well.

Hot Searches