- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XieHe, XieHe

-

Warranty:

-

36 months

-

Model Number:

-

XH-NA009

-

Product Name:

-

Forged Wheels

-

Application:

-

Modified

-

Technology:

-

12000T High Pressure

-

Manufacturing Process:

-

CNC

-

Hole:

-

5 Holes/customized

-

Logo:

-

Custom Logo Accepted

-

Certification:

-

ISO9001-2000,TS16949,VIA

-

Delivery time:

-

10-20 days

Quick Details

-

Finishing:

-

Black

-

Width:

-

5/5.5/7/7.5/8/8.5/9/9.5/10/10.5/11/11.5/12 Inch

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XieHe, XieHe

-

Warranty:

-

36 months

-

Model Number:

-

XH-NA009

-

Product Name:

-

Forged Wheels

-

Application:

-

Modified

-

Technology:

-

12000T High Pressure

-

Manufacturing Process:

-

CNC

-

Hole:

-

5 Holes/customized

-

Logo:

-

Custom Logo Accepted

-

Certification:

-

ISO9001-2000,TS16949,VIA

-

Delivery time:

-

10-20 days

|

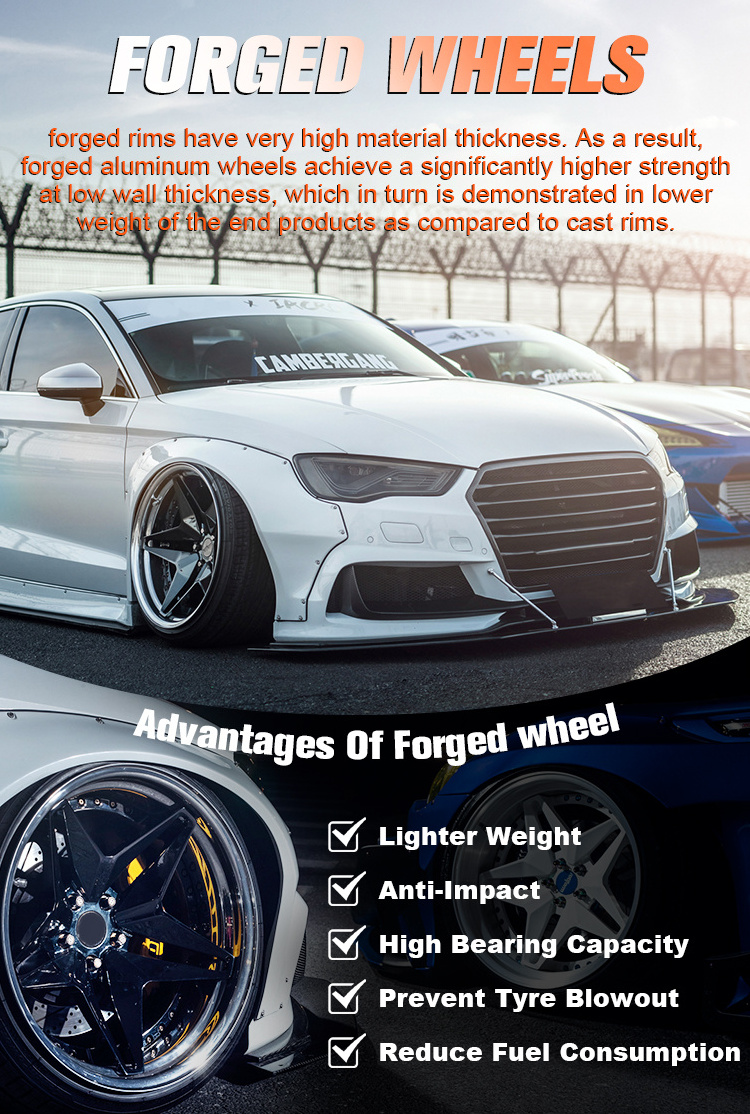

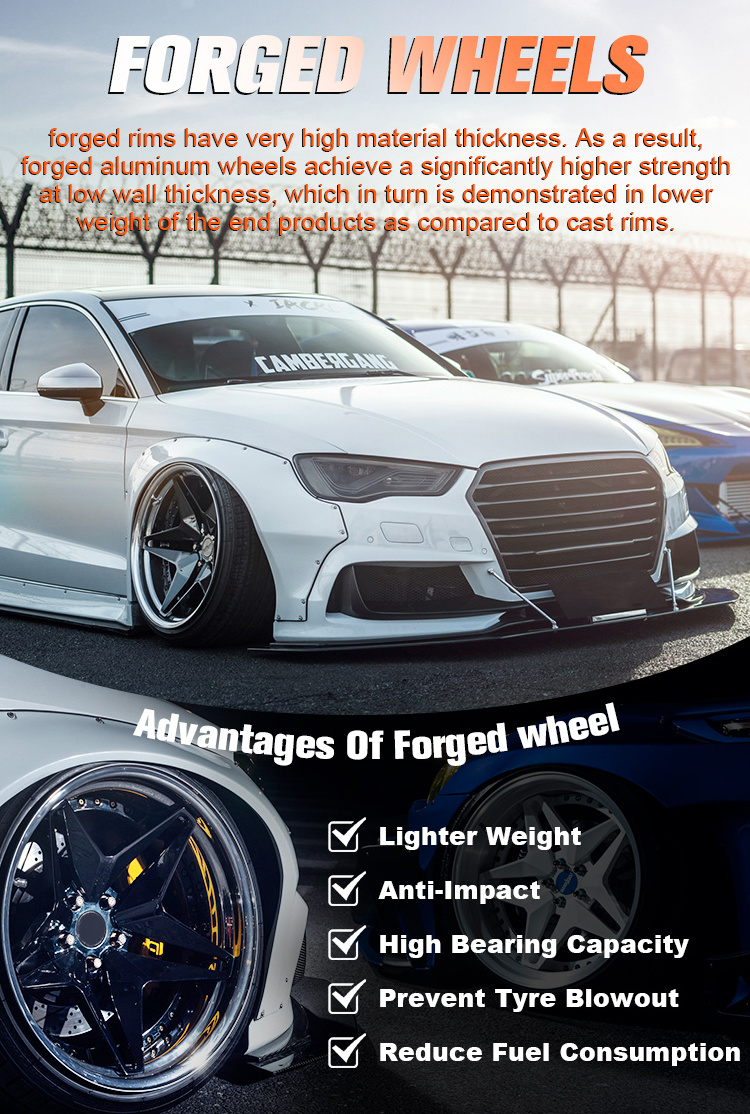

Advantages Of Forged Wheels

|

|

|

||

|

Forged wheels

|

VS

|

Cast wheels

|

||

|

Forged wheels are based on vehicle weight and Safety performance level for wheel structure design higher security

|

Security

|

Cast wheels are mass production driving safety low grade

|

||

|

Forged wheels except for pitch/offset/center hole/ general data such as J value exclusive design for special car .

Also according to brake calipers size to adjust the spoke arc

|

Suitability

|

Cast wheels are not private car does not meet data does not match

|

||

|

Aviation aluminum T6061 high manufacturing cost high density impact resistance strong ability

|

Material

|

Ordinary aluminum melts,low manufacturing cost, density difference, easy to deform and crack

|

||

|

Through the 10,000-ton forging process, the molecular structure of the wheel is tighter,the rigidity is stronger,and the weight is lighter

|

Lightweight

|

Cast wheels are liquid die casting ,craftsmanship relatively simple

|

||

Facts&Figures:

1. Premium design rims

2. Extremely Sophisticated manufactruing process

3. Top quality base material 6061-T6(used in aviation industry)

4. Weight reduction approx. 30% due to higher material density.

5. Thinner spokes achieved by recessed spokes

6. Stronger gloss effect due to a silicon amount of just 0.8%

7. Highest quality ceramic polish with double clearcoat.

|

This product is forged wheels. The required process or product parameters can be customized individually.

|

|

|

||

|

|

|

|

||

FAQ

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us.

2) How can I get a sample to check your quality?

We'll provide sample after you pay sample charge to us. The account is up to your samples, usually it is USD 100-200 per style, but if there are many craft, and it is complex, the sample fee will be higher.

3) How long can I expect to get the sample?

At usual 13-20 days after receive the sample charge & design file.

4) What about the lead time for mass production?

It depends on the order quantity and the season you place the order,Mostly the production time is 15-30 days.

1) When can I get the price?

Hot Searches