- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1-0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

LZ-75 LZ-65 LZ-55

-

Brand Name:

-

Rongsheng

-

Product name:

-

refractory bricks for pizza oven

-

Fe2O3:

-

≤2.5%

-

Crushing strength:

-

40~60 Mpa

-

Bulk Density(kg/m3):

-

2.0-2.5g/cm3

-

Keyword:

-

high alumina brick

-

Feature:

-

High Temperature Resistant

-

Application:

-

Industrial Furnaces

-

Raw material:

-

High Alumina Bauxite

-

Certificate:

-

ISO9001 CE

-

Sample:

-

Provide

Quick Details

-

SiO2 Content (%):

-

-

-

Al2O3 Content (%):

-

48%-85%

-

MgO Content (%):

-

0.8-1.2

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1-0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Henan, China

-

Model Number:

-

LZ-75 LZ-65 LZ-55

-

Brand Name:

-

Rongsheng

-

Product name:

-

refractory bricks for pizza oven

-

Fe2O3:

-

≤2.5%

-

Crushing strength:

-

40~60 Mpa

-

Bulk Density(kg/m3):

-

2.0-2.5g/cm3

-

Keyword:

-

high alumina brick

-

Feature:

-

High Temperature Resistant

-

Application:

-

Industrial Furnaces

-

Raw material:

-

High Alumina Bauxite

-

Certificate:

-

ISO9001 CE

-

Sample:

-

Provide

Product Description

High Alumina Bricks Introduction

High alumina brick is a kind of alumina-silicate refractory material with content of alumina oxide more than 48%. It is calcined and formed by the raw material of banxite or the material with high content of AL2O3. High thermal stability, the refractoriness is more than 1770℃. Good slag resistance, used for the liner of masonry steel-making electric stove, glass furnace and cement revolver.

Feature of high alumina bricks

1. Good thermal conductivity.

2. High fire resistance.

3. Good slag resistance, acid and alkali resistance.

4. Thermal stability.

Features

High Alumina Refractory Bricks Advantage

|

Material

|

high alumina bauxite-Al2O3 content is 48%-85%

|

|

Temperature

|

Refractoriness is above 1770°C,Working temperature:1350°C -1650°C

|

|

Color

|

earthy yellow

|

|

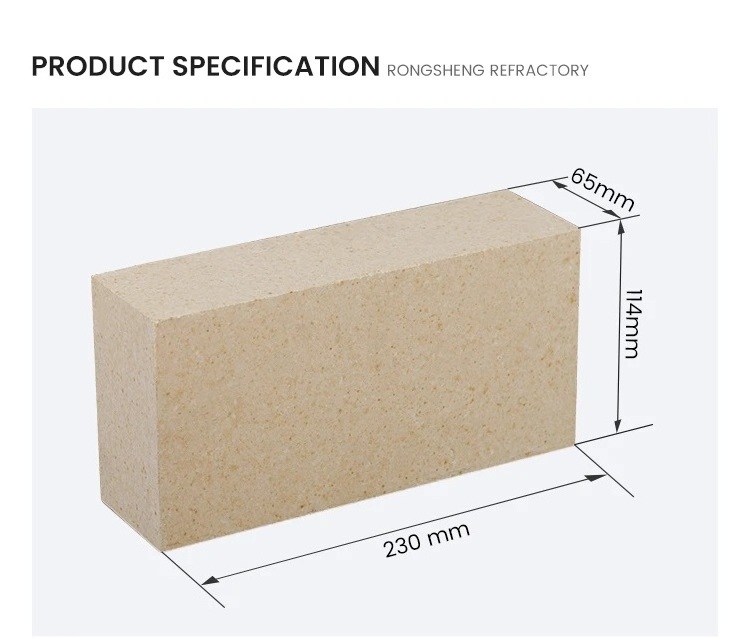

Size

|

Standard sizing: 230 x 114 x 65 mm ,Special size and OEM Service also provide!

|

|

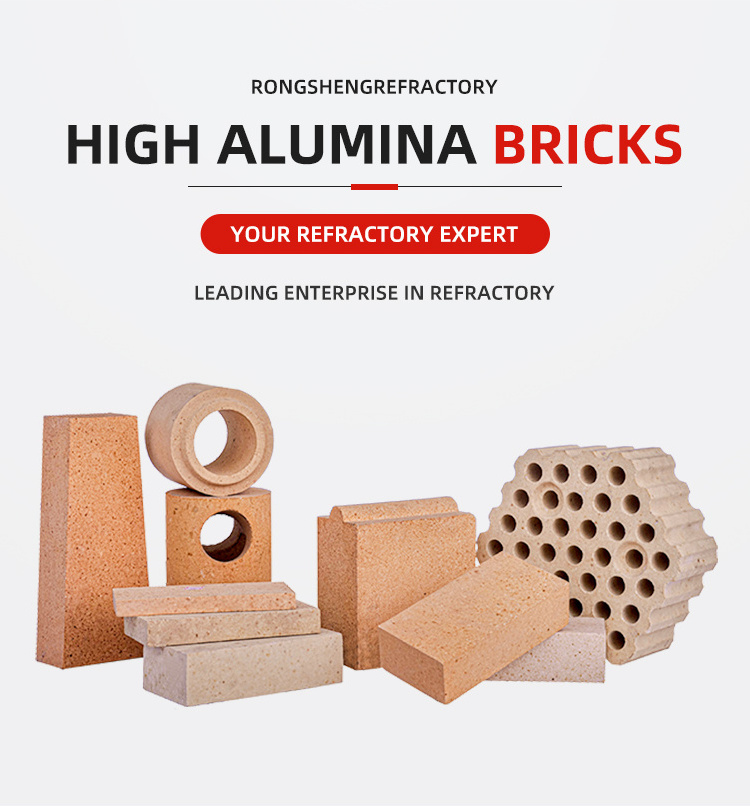

Shape

|

Straight Brick,special-shaped brick,checher brick,trapezoidal brick,Bricks with taper,arch brick,skew brick,ect.

|

Product Application

Use Of High Alumina Bricks

As a basic material in the field of high-temperature technology, high alumina bricks are widely used in cement, glass building materials, steel smelting, petrochemical and other industries. High temperature industrial furnaces for high alumina bricks include blast furnace, hot blast furnace, electric furnace, blast furnace, reverberatory furnace and rotary kiln lining. In addition, high alumina bricks can also be processed into open hearth regenerative grid bricks, socket bricks for pouring system, nozzle bricks, etc. according to the requirements of industrial furnaces.

Specification

|

Item/Grade

|

Fire clay brick

|

|

|

|

High alumina brick

|

|

|

|

||||||

|

|

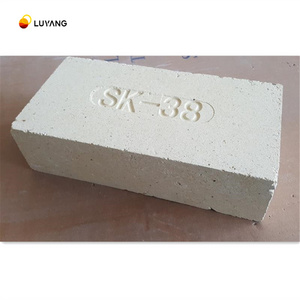

SK-30

|

SK-32

|

SK-34

|

SK-35

|

SK-36

|

SK-37

|

SK-38

|

SK-40

|

||||||

|

AL2O3% (≥)

|

30

|

35

|

38

|

45

|

55

|

65

|

70

|

82

|

||||||

|

Fe2O3% (≤)

|

2.5

|

2.5

|

2

|

2

|

2

|

2

|

2

|

2

|

||||||

|

Refractoriness(SK)

|

30

|

32

|

34

|

35

|

36

|

37

|

38

|

40

|

||||||

|

Refractoriness under load, 0.2MPa, °C (≥)

|

1250

|

1300

|

1360

|

1420

|

1450

|

1480

|

1530

|

1600

|

||||||

|

Apparent porosity (%)

|

22-26

|

20-24

|

20-22

|

18-20

|

20-23

|

20-23

|

20-22

|

18-20

|

||||||

|

Bulk density (g/cm³)

|

1.9-2.0

|

1.95-2.1

|

2.1-2.2

|

2.15-2.22

|

2.25-2.4

|

2.3-2.5

|

2.4-2.6

|

2.5-2.7

|

||||||

|

Cold crushing strength ,MPa (≥)

|

20

|

25

|

30

|

40

|

45

|

50

|

60

|

70

|

||||||

Packaging & Shipping

Wooden pallets with plastic film or according to your request.

1. Strong packing protects the goods from any possible damage during transit.

2. Solid packing and overall stuffing prevent the cases from vibration and jarring.

3. Necessary precaution is taken to protect goods from pilferage or rain.

Every possible precaution is taken to ensure our products in prime condition when reach customers around the world.

By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

Our Advantages

There are 240 staffs in Rongsheng Company, of which 12 is senior professional technician. Annual production capacity is up to 60000 tons. There are light and heavy weight materials production lines and all kinds of complete production, testing and check equipment, of which there are 10 series shaped press machine that from 400 tons to 1000 tons and two hyperthermia tunnel kilns whose length are 148m and 118m.

Rongsheng Refractory has established complete quality system and conducted quality control through the whole staff and process that from raw materials, production, check and various parts strictly according to ISO9001 standard and with the professional checker at each level to take good product and service as the top goal.

Hot Searches