The RICHI

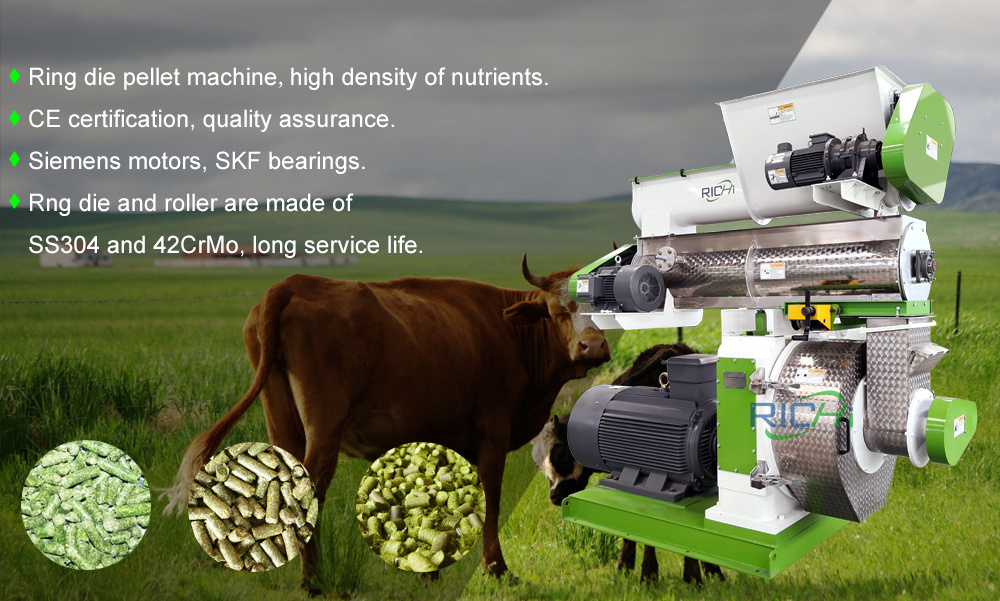

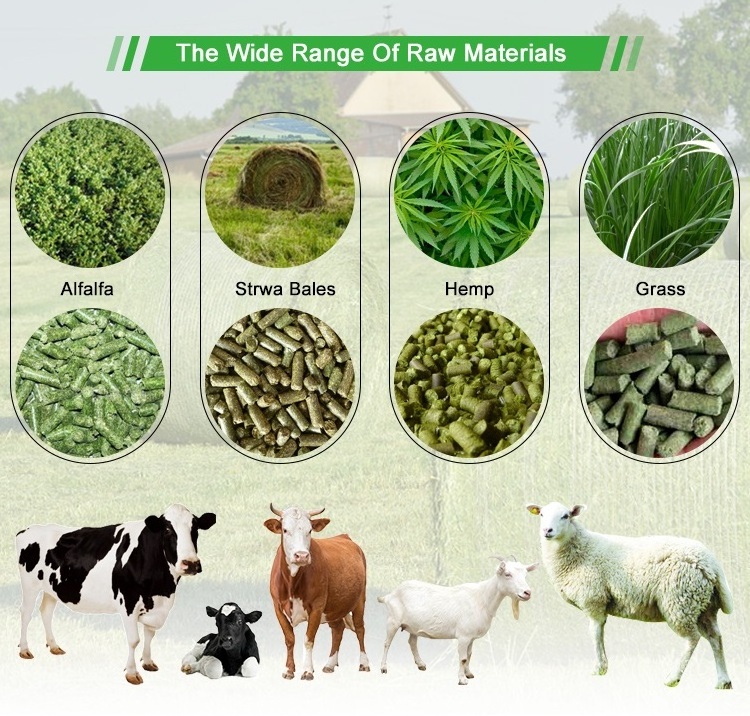

Large Farms Use 1-6 T/H Hemp Alfalfa Grass Production Line

can make various agricultural raw materials such as grass, straw, corn stalks, wheat straw, crop straw, sorghum straw, alphagrass, alfalfa grass, hemp, hops etc into animal feed pellets. There are many benefits by making various grasses into animal feed pellets, such as improving the palatability of the feed and convenient storage.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V/440V/480V (Voltage in your country)

-

Dimension(L*W*H):

-

According to specific design

-

Weight:

-

11000 kg

-

Marketing Type:

-

New Product 2023

-

Name:

-

1-6 T/H Hemp Alfalfa Grass Production Line

-

Raw material:

-

Hemp Alfalfa Grass

-

Material:

-

304 Stainless Steel

-

Processing Types:

-

Electricity

-

Keywords:

-

Hemp Alfalfa Grass Production Line

-

Feature:

-

Long Servicing Time

-

Capacity:

-

1-6 T/H

-

Advantage:

-

High Capacity High Efficient

-

Motor:

-

Siemens Motor

-

Feed types:

-

Automatic Feeding Fork

Quick Details

-

Max. Capacity:

-

1-6 T/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RICHI

-

Voltage:

-

380V/415V/440V/480V (Voltage in your country)

-

Dimension(L*W*H):

-

According to specific design

-

Weight:

-

11000 kg

-

Marketing Type:

-

New Product 2023

-

Name:

-

1-6 T/H Hemp Alfalfa Grass Production Line

-

Raw material:

-

Hemp Alfalfa Grass

-

Material:

-

304 Stainless Steel

-

Processing Types:

-

Electricity

-

Keywords:

-

Hemp Alfalfa Grass Production Line

-

Feature:

-

Long Servicing Time

-

Capacity:

-

1-6 T/H

-

Advantage:

-

High Capacity High Efficient

-

Motor:

-

Siemens Motor

-

Feed types:

-

Automatic Feeding Fork

Animal Feed Pellet Line Overview

Description Of The RICHI

Large Farms Use 1-6 T/H Hemp Alfalfa Grass Production Line For Animal Feed Pellet

:

Raw Materials To Pellets

Advantages Of

Large Farms Use 1-6 T/H Hemp Alfalfa Grass Production Line For Animal Feed Pellet

:

-

It can better preserve the nutrients in the raw materials:

During the conditioning process, silage has weak oxidative decomposition and low nutrient loss (3%-10%). It can preserve most of the nutrients in forage grass and forage crops, especially carotene in green feed.

-

Some cellulose can be degraded:

Crop straw can be softened during the silage process, so that part of the crude fiber can be degraded and the digestibility can be improved.

-

It can be stored for a long time under sealed conditions:

The silage can be stored for many years, so that the green fodder can be used in a balanced manner throughout the year.

-

It can improve palatability:

The silage is tempered by the optional conditioner of the RICHI pelleting machine, and the pellets are matured to improve the palatability and the livestock likes to eat.

-

Silage can kill certain disease sources of crops and can inactivate weed seeds:

In the process of making silage pellets, it can kill insects and weed seeds and inhibit the activities of various microorganisms; it is conducive to the use of physicochemical and biological technologies to improve the nutritional value of feed.

-

Wide sources of raw materials:

RICHI feed pellet machine can make various grass and straw crops into feed pellets, such as corn stalks, wheat stalks, alfalfa, industrial hemp leaves, weeds and other raw materials.

Process Flow

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The grass crushing system can make agricultural waste (such as grass ,alfalfa,rice husk, hemp) into grass sawdust . The hammer mill is applied mainly to grinding the raw material to make it suitable to make pellets. The hammer mill is composed of electric motor, couping, bearing, rotor, hinge pin, hammers 8mm pore size sieve plate.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

To dry materials and remove the moisture from 50 % to 15-17 % . It includes: Burning stove, to supply hot air; Drum dryer; Discharging cyclone. The best moisture content to pelletizing is 13-15%,so our rotary dryer is designed to reduce the moisture of the unqualified raw material, for which the moisture is too high.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The pelletizing system to make grass powder into grass pellets. The pellet machine is the main equipment in the production line to make pellets, it compress the dry finely pulverized material and transform them into a cylinder shape pellet at a temperature of 80 degree. The pellet size from 2-12mm can be adjuist .

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The cooling system can cool the down to room terperature immediately, pellets come out from pellet machine, its temperature is around 70°C,by momentary cooling, the hardness of pellets will become more stronger. Thus to acquire better hardness and strength. Also it can enhance the transport ability and storage aility.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Product Parameters

|

Main Equipment And Technical Parameters Of The Large Farms Use 1-6 T/H Hemp Alfalfa Grass Production Line For Animal Feed Pellet:

|

|

|

||

|

Notes: We provide customized feed pellet production lines with capacities ranging from 1T/H to 100T/H.

|

|

|

||

|

Machine Name

|

Single Power (Kw)

|

Capacity(T/H)

|

||

|

Hammer Mill

|

22-93

|

0.5-4

|

||

|

Rotary Dryer

|

15

|

0.3-5

|

||

|

Pellet Making Machine

|

22-280

|

0.7-40

|

||

|

SKLN Series Cooler

|

0.75-1.5

|

1.5-18

|

||

|

Screener Machine

|

1.5-5.5

|

3-20

|

||

|

DCS Serise Packing System

|

1.1-5

|

6-12 Bags/Min

|

||

|

MCC Control Center ;Mimic control panel

|

/

|

/

|

||

|

Note: The equipment parameters and the specific details of the production line will depend on different raw materials, capacity and designs.

|

|

|

||

Project Cases

Hot Searches