- Product Details

- {{item.text}}

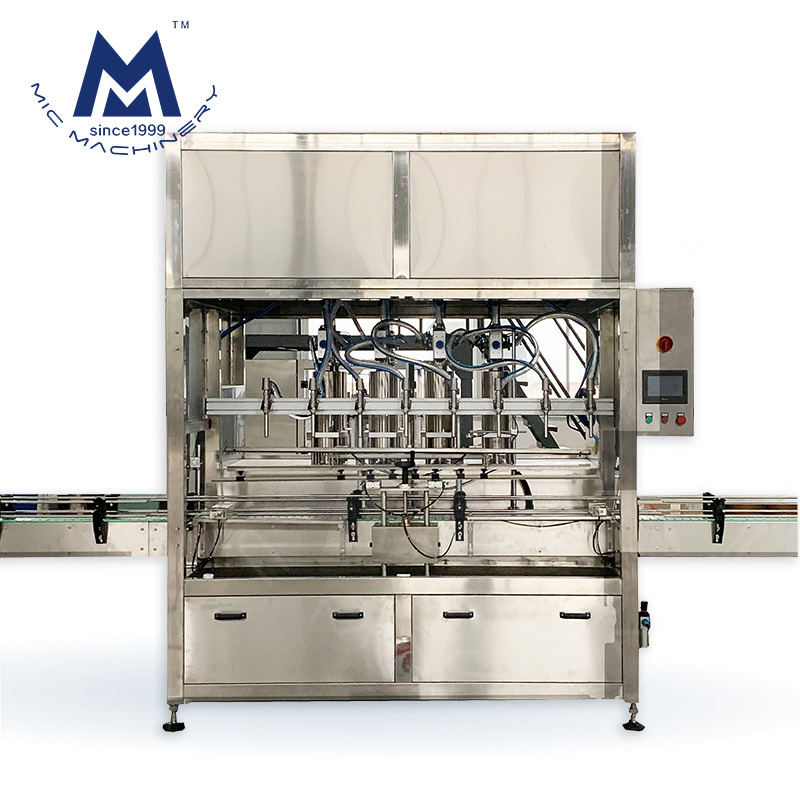

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V 50HZ, 220V/380V 50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

2000*900*2000mm

-

Weight:

-

1000 KG

-

Product name:

-

oil filling capping machine

-

Filling volume:

-

Under 5liters

-

Filling nozzle:

-

2-20nozzles

-

Filling speed:

-

customized

-

Machine material:

-

SUS304/316

-

Control:

-

PLC+ Touch Screen

-

Air pressure:

-

0.6 MPa

-

Suitable bottle:

-

Plastic or glass bottle

-

Operator:

-

1-2people

Quick Details

-

Machinery Capacity:

-

Customized

-

Packaging Material:

-

Wood

-

Filling Material:

-

Other, Oil

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V 50HZ, 220V/380V 50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

2000*900*2000mm

-

Weight:

-

1000 KG

-

Product name:

-

oil filling capping machine

-

Filling volume:

-

Under 5liters

-

Filling nozzle:

-

2-20nozzles

-

Filling speed:

-

customized

-

Machine material:

-

SUS304/316

-

Control:

-

PLC+ Touch Screen

-

Air pressure:

-

0.6 MPa

-

Suitable bottle:

-

Plastic or glass bottle

-

Operator:

-

1-2people

The machine adopts PLC control, according to the filling bottle, fixed discharging mouth, the rest all operation can be finished on a touch screen. In addition to have common automatic servo piston filling machine advantages, also the widened the range of filling material. Such as filling material contains

particles, long strips of solid content, also can be a very effective filling.

This machine adopts serve ball-screw system to drive the piston cylinder. It's widely used in Food, Chemical Cosmetics, Agrochemical industry, applicable for filling liquid, especially for high viscosity material and foamy liquid, such as: Oil, Sauce, Ketchup, Honey, Shampoo, Lotion Lubricant oil, etc.

|

Weight

|

700KG

|

|

Power

|

customized

|

|

Filling Volume

|

100-1000ml

|

|

Filling Error

|

≤3%

|

|

Suitable Filling Material

|

Oil,shampoo,detergent,sauce, honey, etc

|

|

Suitable Barrel Width

|

120-250mm

|

|

Dimension

|

2000*1300*2200mm

|

|

Power

|

1.5Kw

|

|

Filling nozzle

|

8 nozzles

|

|

Capacity

|

≤3000BPH

|

|

Suitable Barrel Length

|

180-330mm

|

|

Suitable Barrel Height

|

80-450mm

|

Filling Heads

Every filling head has anti-drop design. It promise do not waste the material. And diameter of filling head basis on the diameter of customer’s barrel’s mouth.

Piston Cylinder

The piston is drawn back in its cylinder so that the product is sucked into the cylinder. A rotary valve then changes position so that the product is then pushed out of the nozzle instead of back into the hopper.

Servo Motor

Servo motor can control the filling more accurate and also it can realize the filling nozzle diving bottom-up filling. At the same time, the filling volume can be adjusted on the touch screen and has automatic fine turning function for each filling head.

Anti-dripping system

This function is for prevent material dripping on the bottle and conveyor. And there will be a flexible plate coming out and back to take the dripping materials

Take off piston cylinder cleaning

piston will take off from the cylinder automatically ,then it will clean the Remaining materials that remain in the material tank and cylinder

Hot Searches