Adopt adjustable round wheel design.

Small error good operation.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Howann

-

Voltage:

-

380/415/420/440V

-

Power:

-

15kw

-

Dimension(L*W*H):

-

12.5*1.3/1.7m

-

Weight:

-

7000 kg

-

Product Name:

-

Pipe Making Machinery

-

Frame Materials:

-

350H steel

-

Forming Shaft:

-

Material 45# quenched and tempered

-

Cutting System:

-

Flying saw cutting

-

Electric tension:

-

380V 50 Hz 3 Phase or as your requirements

-

Main Engine power:

-

5.5 KW with cycloidal reducer

-

Motor:

-

15KW

-

Pumping station:

-

5.5KW

-

Welding machine:

-

TIG welding /Plasma welder /Panasonic welder

-

Certificate:

-

CE, ISO

Quick Details

-

Pipe Material:

-

Stainless Steel;Carbon Steel

-

Production Capacity:

-

20m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Howann

-

Voltage:

-

380/415/420/440V

-

Power:

-

15kw

-

Dimension(L*W*H):

-

12.5*1.3/1.7m

-

Weight:

-

7000 kg

-

Product Name:

-

Pipe Making Machinery

-

Frame Materials:

-

350H steel

-

Forming Shaft:

-

Material 45# quenched and tempered

-

Cutting System:

-

Flying saw cutting

-

Electric tension:

-

380V 50 Hz 3 Phase or as your requirements

-

Main Engine power:

-

5.5 KW with cycloidal reducer

-

Motor:

-

15KW

-

Pumping station:

-

5.5KW

-

Welding machine:

-

TIG welding /Plasma welder /Panasonic welder

-

Certificate:

-

CE, ISO

Product Description

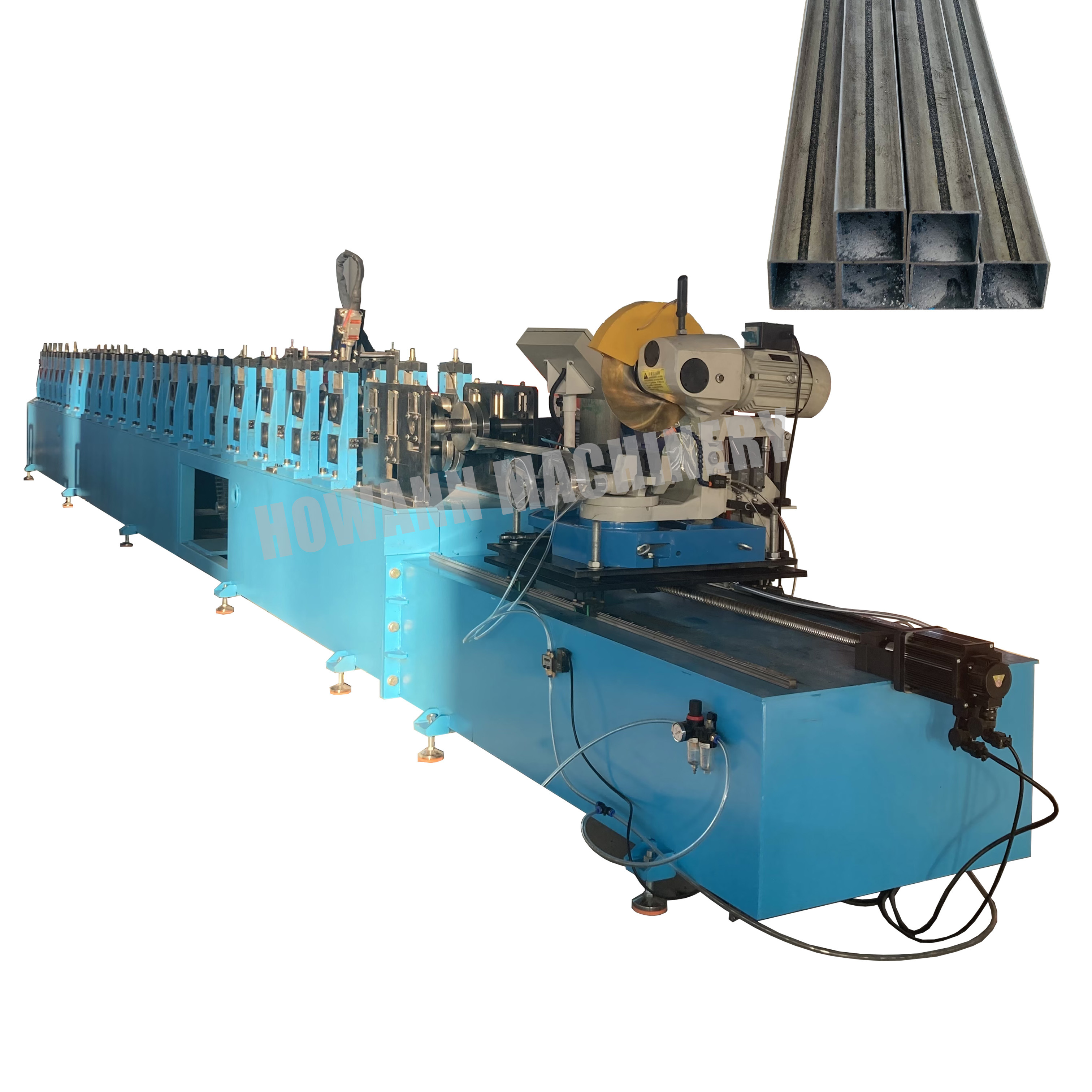

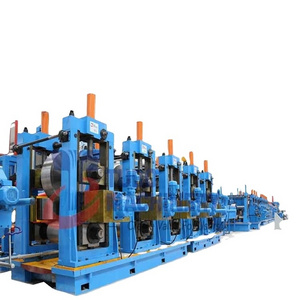

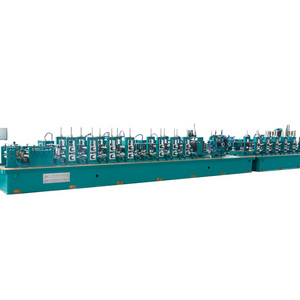

Pipe Making Machine

Pipe making machines are mainly used to produce industrial stainless steel pipes, which are widely used in chemical industry, medicine, brewing, petroleum, food, automobiles, papermaking, air conditioning and other fields. The pipe making machine is newly designed based on the actual production and absorbing the advantages of domestic and foreign equipment. It is easy to operate and maintain.

The whole production line includes machines from uncoiler to cutting saw. Welding speed can be adjusted according to the pipe diameter, thickness and length.

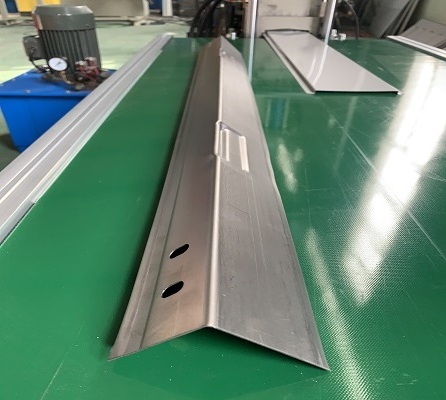

The following are the specifications of the two most common shapes we provide, and the specific shapes can be customized according to customer requirements (punching is optional).

The following are the versions we have sold, you can also send me your drawings, we will customize the machine for you.

Our

Advantanges:

1.Produce different purlin size without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost.

4.Infinite sizing(any size within machine range),help to save material.

5.Optional Punch hole at any position of purlin web side and flange side.

The Working Flow

Manual uncoiler---feeding device---rolling form---speed, length, pieces set by PLC---hydraulic mold post cutting---collection table

|

|

|

|

|

|||||

|

Product name

|

Pipe Making Machine

|

|

|

|

||||

|

Frame materials

|

350H steel

|

|

|

|

||||

|

Diameter

|

80mm

|

|

|

|

||||

|

Forming roller

|

14-16row

|

|

|

|

||||

|

Forming shaft

|

Material 45# quenched and tempered

|

|

|

|

||||

|

Max.speed

|

20m/min

|

|

|

|

||||

|

Feeding width

|

As Required

|

|

|

|

||||

|

Cutting system

|

Flying saw cutting

|

|

|

|

||||

|

Main engine power

|

22 KW with cycloidal reducer

|

|

|

|

||||

|

Voltage

|

380V 50 Hz 3 Phase or as your requirements

|

|

|

|

||||

|

Hydraulic oil

|

40# hydraulic oil

|

|

|

|

||||

|

Material of cutting table

|

Cr 12 mould steel with quenched treatment

|

|

|

|

||||

|

Applicable industries

|

Building Material Shops, Manufacturing Plant, Construction works

|

|

|

|

||||

|

|

|

|

|

|||||

Feeding table

Welding Section

Welding tracking system

The welding automatic correction

The welding arc voltage automatic control

Material of the roller: High grade No.45 forged steel

Roller station: 14-16 rows

Thickness of feeding material: 0.3-0.6mm

Flying saw cutting

More efficient and time-saving

Automatic activation.

More efficient and time-saving

Automatic activation.

Metal Saw Cutter

Less burr in the end of the pipe

Less burr in the end of the pipe

If you are interested in our products, please do not hesitate, you can contact us directly, I believe we will have a good cooperation.

Details Images

Our Advantages

Hot Searches