- Product Details

- {{item.text}}

Quick Details

-

Model:

-

FCA10-11

-

Production efficiency:

-

2.8-5s/mould

-

Compressed air capacity:

-

0.4~0.7m3/mim

-

Total weight:

-

16t~17t

-

Compressed air pressure:

-

0.7mpa

-

Cooling water:

-

1t/hr

-

Installed power:

-

148kw

-

Certification:

-

ISO/CE, ISO CE

-

Weight:

-

12T

-

Power:

-

150kw

Quick Details

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Name:

-

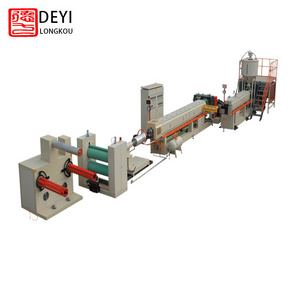

ps foam food box production line plastic foam plate machine

-

Model:

-

FCA10-11

-

Production efficiency:

-

2.8-5s/mould

-

Compressed air capacity:

-

0.4~0.7m3/mim

-

Total weight:

-

16t~17t

-

Compressed air pressure:

-

0.7mpa

-

Cooling water:

-

1t/hr

-

Installed power:

-

148kw

-

Certification:

-

ISO/CE, ISO CE

-

Weight:

-

12T

-

Power:

-

150kw

This forming and cutting incorporated machine designed by our company is all-powerful. The main way is vacuum forming as well as press forming and synthetical forming. It can be used for forming kinds of plastic sheet. This machine adopt PLC control, it has group possesses reliable stability, large forming area, high production and automatic degree. The machine can mainly forming the PSP material which is used to produce food container, tray, bowl, cup etc. Forming, cutting, stacking are done in the same machine, saving labor, improving efficient, lowing labor intensity and reducing production cost. Production process is to put foam sheet into forming machine, and product and wastage will come out from the rear part.

More Details of ps foam food box production line plastic foam plate machine

Part-1 Unwinding unit

1. Photoelectric switch control auto feeding

2. Unwinding mode:0.75kw turbine decelerating motors

3. Unformed PS placing unit, the feeding of PS foam sheet is automatically driven by cylinder, rubber covered roller is used to unroll the PS foam sheet.

Photoelectric switch control, and contain two PS foam sheet rollers. Taking turns utilization.

Part-2: Heating Unit

1. Temperature control

Intelligent temperature controller and temperature control module, to control temperature and adjust the both sides voltage of heater, keeping heater constant temperature heating status.

2. Maintenance design: Heating box can be moved back and forth. heating mode: ceramic tile radiation

3. Heating area: 1250*24 00mm

Heating zone: 52pcs

Heating power: 121.5kw

Part-3: Vacuum forming unit

- Forming area 1100mm×1000mm

- Forming pressure 20T

- Hydraulic oil pump motor: 7.5KW X 1sets

- Forming depth 100mm(Maximum)

- Vacuum tank: 115L*2 pcs + 50L*1pc

- Vacuum pump Water-ring type 7.5kw

Part-4: Truncation unit

- Cutting pressure 120T Maximum

- Cutting type Hydraulic cutting system

- Cutting oil pump motor: 11KW

- Cutting area 1100*1000mm

1. Punching plate: High quality stainless steel

2. Working table stroke: Photoelectric switch automatic control

Part-5: Mechanical arm collectiong unit

1) Stacking method: The servo motor control the mechanical arms reciprocating motion, the mechanical arms catch the plate by vacuum sucker,

it uses conveyor belt to collect the plate from both sides.

2) Control method: PLC control

servo motor: 1.5kw*2 sets; 3kw*1sets

Apllication of fast food container machine

Q:How to choose model?

A:Tell me your requirement (box size and capacity),we will help you to choose one accordingly.

Q:Why I choose your company?

A: a. We are China Leading foam machine Manufacturer.

b. our company have made foam machine for many years with strong

experience and advanced technics

c. Best Quality & Best Service with Competitive price.

d. 100% inspection Before Shipment. And we have got CE certificate

e. we have Professional technical team, will supply 24 hours service

f.our machine have good quality, 1 year guarantee and lifetime maintenance

Q:What is the material of PS foam sheet production line?

A:Polyethylene, Talcum powder, Butane, Nitrogen

Q:What should we prepare except material?

A:You should prepare workshop, water line, electric line, compress air(if you need I can help you buy air compressor)

We can supply workshop layout drawing.

Q: can you make machine upon our requirement?

A: of course, it is no problem, we can make machine according to your requirement, such as part brand, machine color, labels, moulds, etc.