- Product Details

- {{item.text}}

Quick Details

-

Item:

-

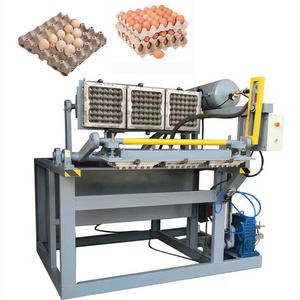

egg dish making prodution line Automatic type paper pulp mold

-

Raw material:

-

Waste Paper/recycling paper/used paper

-

Fuel type:

-

natural gas/diesel oil/coal

-

Output paper:

-

Craft Paper

-

Capacity:

-

4000PCS/hour~8000PCS/h/as your request

-

Feature:

-

fully automtic

-

Finished Products:

-

Egg Tray Egg Carton

-

Application:

-

egg tray/egg carton/egg plate

-

Production:

-

paper pulp egg tray moulding

Quick Details

-

Production Capacity:

-

4000PCS/hour~8000PCS/h

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Item:

-

egg dish making prodution line Automatic type paper pulp mold

-

Raw material:

-

Waste Paper/recycling paper/used paper

-

Fuel type:

-

natural gas/diesel oil/coal

-

Output paper:

-

Craft Paper

-

Capacity:

-

4000PCS/hour~8000PCS/h/as your request

-

Feature:

-

fully automtic

-

Finished Products:

-

Egg Tray Egg Carton

-

Application:

-

egg tray/egg carton/egg plate

-

Production:

-

paper pulp egg tray moulding

Automatic gg dish making prodution line food tray machine Automatic gg dish making prodution line food tray machine Automatic gg dish making prodution line food tray machine Automatic gg dish making prodution line food tray machine Automatic gg dish making prodution line food tray machine Automatic gg dish making prodution line food tray machine

Automatic gg dish making prodution line food tray machine

Product Type:

Automatic egg dish making prodution line food tray machine

Processing Type:

Waste Paper Pulp Molding Machine

Approval:

CE

Warranty:

12 Monthes

Rotary:

2 /4 /8 /12 Faces

Forming Platen Size:

1600 x 400 mm / 1950 x 420 mm / 2350 x 420 mm

Capacity:

1500 – 20000 pcs/hr (30-egg tray)

Matches with 6-layer dryer, energy efficient and conserve energy

Automatic gg dish making prodution line food tray machine equipped with automatic hot pressing and intelligent conveying stacking technology.

Mainly applied for egg tray, egg carton, fruit tray, cup carrier, bottle tray etc.

Flow Chart of Automatic egg dish making prodution line food tray machine

For paper pulp egg tray moulding 30-cell egg trays : first the worker will weight the raw material and put them into the conveyor.

Then the pulping ,forming, drying and stacking will be finished automatically. After drying, the finished products will be packed by workers.

A hot pressing section should be added in the production of pulp molded egg box/carton(6-cell,10-cell,12-cell,6+6-cell,15-cell),fruit tray and cup carrier after drying because of shrinking.

The egg box/carton can be labelled or printed after hot pressing. These processes could be finsihed manually or automatically.

Technology Parameters of Automatic egg dish making prodution line food tray machine

|

Model |

1500-20000 |

|

Forming width |

410-710MM(460-760MM materials) |

|

Forming length |

600-1220MM |

|

Forming height |

200MM |

|

Thickiness of materials |

0.2-1.5MM |

|

Production power |

220-500times/hour(according to products) |

|

power |

380Vs/220Vs/50Hzs(Three mutually four lines) |

|

Furnace power |

18-35KW |

|

Required to install air pump |

20HP |

|

Mechanistic Dimensions |

L6800*W1600*H2650MM |

|

Net weigh |

3000KG |

Some of the Advantages of Automatic egg dish making prodution line food tray machine

1. Raw material

: all waste paper like old newspaper,magazines,books,A4 paper etc, and easy to get.

2. Automation:

Fully-automatic control

3. Quality standard:

CE

4. 100% environmentally

production process.

5. Engineers available

to service machinery overseas

Packaging&shipping of Egg tray making machine paper pulping paper pulp egg carton molding machine factory

High quality of paper pulp egg tray moulding for paper trays could design according to the customer’ requirement.

1.Our mainly transport is shipping .

2. Any transport you need, we can offer according to your requirement!

Pre-sales services

* All information about our machine by email/phone will be replied ASAP.

* We help customers to design the layout of the machine in workshop.

* according to the customers’ requirements and circumstance to make the best egg tray production line design .

* support factory to prepare.

In the sale of services

* we are in charge of installing,debugging and training

* technical guidance

* test the machine in the factory before the delivery

After-sales service

* one year guarantee for whole machine include the spare parts

* calling, network or door-to-door service

* use friendly English software, user manual and detailed Videos/CD

* engineers can be sent to the buyers' countries