This equipment has low investment and high return.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Lukes

-

Voltage:

-

380V 50HZ 3 Phase, 380V 50HZ 3 Phase

-

Dimension(L*W*H):

-

2000*2010*1900mm

-

Weight:

-

3500 kg

-

Max.sheet Size:

-

1040 720mm

-

Max.rule length:

-

<28m

-

Working pressure:

-

300tons

-

Working speed:

-

23±3

-

Total power:

-

4kw

-

Stock rage:

-

60-2000g cardboard

-

Air compressor:

-

0.3m3/min

-

Total weight:

-

3500kg

-

Dimension:

-

2000 2010 1900mm

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

120 sheets/min

-

Max. workable width:

-

1040 720mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Lukes

-

Voltage:

-

380V 50HZ 3 Phase, 380V 50HZ 3 Phase

-

Dimension(L*W*H):

-

2000*2010*1900mm

-

Weight:

-

3500 kg

-

Max.sheet Size:

-

1040 720mm

-

Max.rule length:

-

<28m

-

Working pressure:

-

300tons

-

Working speed:

-

23±3

-

Total power:

-

4kw

-

Stock rage:

-

60-2000g cardboard

-

Air compressor:

-

0.3m3/min

-

Total weight:

-

3500kg

-

Dimension:

-

2000 2010 1900mm

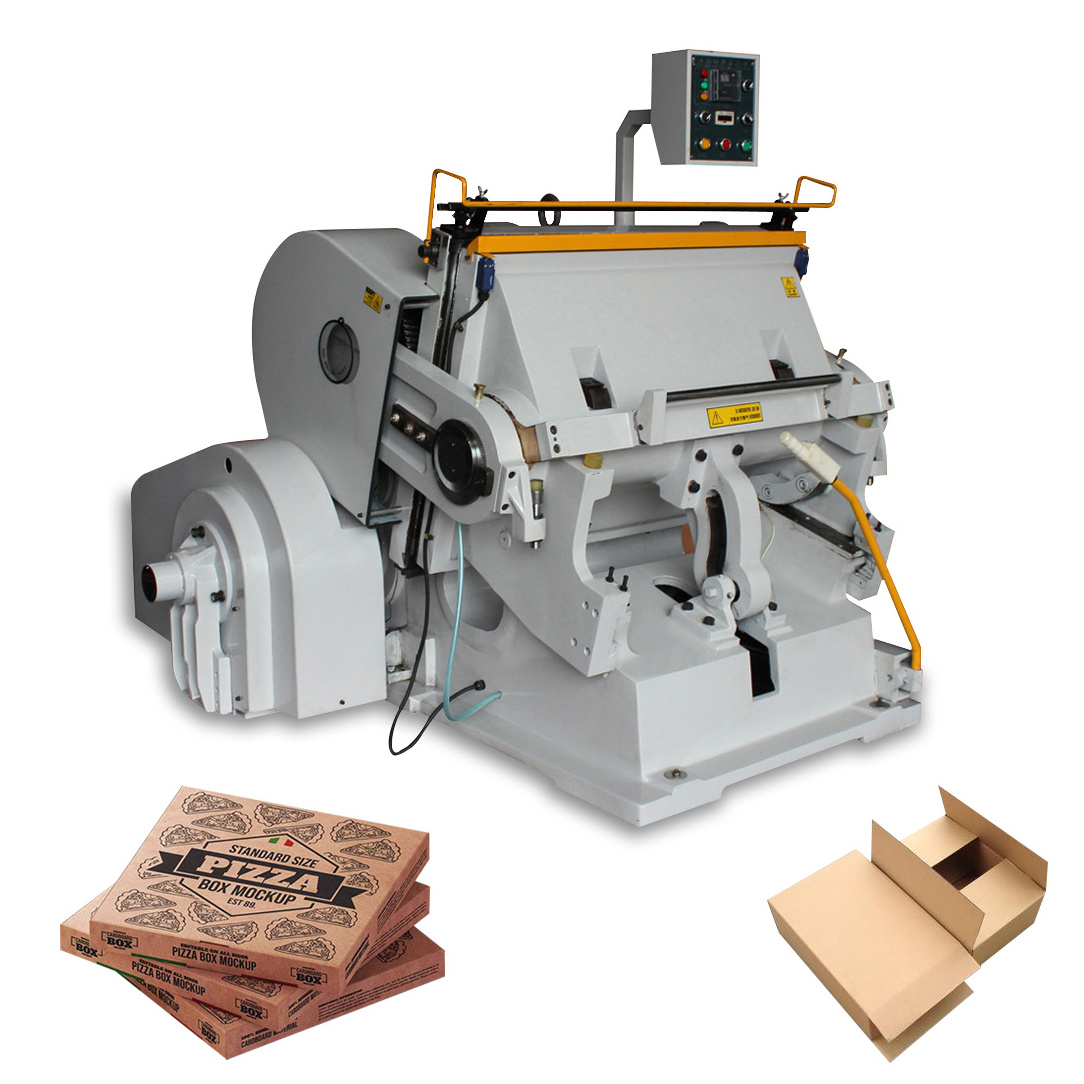

ML1040 High Speed Hand Fed Platen Flat Bed Paper Box Making Manual Die Cutting Creasing Machine

ML Series Manual Die Cutting Creasing Machine

It is mainly used for die cutting (full cut, half cut) of cardboard, PVC, leather cork, self-adhesive, EVA, double-sided tape, electronics and other materials. It is an important equipment for post-press packaging processing and molding.

Different shapes of cartons can be formed according to your molds.

|

Model

|

Inner chase size

|

Speed

|

Max. rule length

|

Motor power

|

Weight

|

Dimension

|

|

ML750

|

750X520mm

|

25

|

< 15m

|

2.2kw

|

2000kg

|

1650x1400x1500mm

|

|

ML930

|

930X670mm

|

23 +3

|

< 25

|

4kw

|

3000kg

|

1750x1900x1700mm

|

|

ML1040

|

1040x720mm

|

23 +3

|

< 28m

|

4kw

|

3500kg

|

2000x2010x1900mm

|

|

ML 1100

|

1100x800mm

|

22+ 3

|

< 35m

|

5.5kw

|

4500 kg

|

2000x2010x1900mm

|

|

ML 1200

|

1200x820mm

|

20 +2

|

< 32m

|

5.5kw

|

5000kg

|

2020x2020*1950mm

|

|

ML 1300

|

1300x920mm

|

15 +2

|

< 40m

|

7.5kw

|

6000kg

|

2600*2100*1950mm

|

|

ML 1400

|

1400x1000mm

|

15 +2

|

< 45m

|

7.5kw

|

7000kg

|

2600*2100*1950mm

|

|

ML 1500

|

1500x1050mm

|

14+ 2

|

< 45m

|

7.5kw

|

7500kg

|

2650*2100*2000mm

|

|

ML 1600

|

1600x1250mm

|

13 + 2

|

< 50m

|

11kw

|

11500kg

|

2850*2250*2100mm

|

|

ML 1800

|

1800x1400mm

|

13 + 2

|

< 60m

|

15 kw

|

13000kg

|

3150*2250*2250mm

|

|

ML 2000

|

2000x1400mm

|

12 +2

|

< 65m

|

15 kw

|

15500kg

|

3150*2250*2300mm

|

|

ML 2200

|

2200x1400mm

|

12 +2

|

< 68m

|

18 kw

|

16500kg

|

3300*2250*2300mm

|

|

ML 2500

|

2500x1500mm

|

12 +2

|

< 70m

|

22kw

|

18500kg

|

3600*2250*2500mm

|

|

ML 2600

|

2600x1500mm

|

12 +2

|

< 70m

|

22kw

|

2000kg

|

3700*2250*2500mm

|

|

ML 2800

|

2800x1500mm

|

12 +2

|

< 75m

|

22kw

|

2300kg

|

3900*2300*2800mm

|

|

ML 3000

|

3000x1600mm

|

12 +2

|

< 80m

|

30kw

|

35000kg

|

4200*2300*3000mm

|

Features:

1. It is characterized by compact structure, fine workmanship, high pressure, high precision and easy and reliable operation.

2.High strength due to whole body casting with high quality material.

3. Smooth running, high pressure and low noise with 4-step helical gear mechanism.

4. Single plate electromagnetic clutch is sensitive and reliable.

5. Operational altitude is reasonably arranged, moving-bed opens to its maximum.

6. Electrical system is designed in conformity with IEC standard.

7. The functions of single operation, continuous operation and opening delay are available; delay range is adjustable.

8. Reliable safety system.Concentrated lubricating system.

9. The lubrication system of centralized refueling and manual refueling (optional) can better guarantee the smooth oil path and

facilitate the maintenance of the lubrication system.

10. The shaft sleeve of the transmission part adopts compound copper sleeve (to ensure lubrication) and pure copper copper sleeve of the connecting rod.Make the machine more precise.

2.High strength due to whole body casting with high quality material.

3. Smooth running, high pressure and low noise with 4-step helical gear mechanism.

4. Single plate electromagnetic clutch is sensitive and reliable.

5. Operational altitude is reasonably arranged, moving-bed opens to its maximum.

6. Electrical system is designed in conformity with IEC standard.

7. The functions of single operation, continuous operation and opening delay are available; delay range is adjustable.

8. Reliable safety system.Concentrated lubricating system.

9. The lubrication system of centralized refueling and manual refueling (optional) can better guarantee the smooth oil path and

facilitate the maintenance of the lubrication system.

10. The shaft sleeve of the transmission part adopts compound copper sleeve (to ensure lubrication) and pure copper copper sleeve of the connecting rod.Make the machine more precise.

Factory Direct Sales

Reduce the price difference between middlemen, the price is more favorable, and the factory is directly after-sale.

Excellent Raw Materials

Selected safe and high-quality materials, durable and long service life

Quality Assurance

Strict quality inspection system to ensure the quality of each product leaving the factory

Manual die cutting machine also was called Die Cutting Machine or Platen Punching & Creasing Press , which is mainly used for cardboard, corrugated cardboard, plastic and leather , applicable to printing packaging decoration and plastic industries.

Send your Inquiry Details in the Below, Click "Send" !

we will reply within 24h!

Hot Searches