- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

38891-59-7

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HiGlue

-

Model Number:

-

111

-

Type:

-

Epoxy Iron Repair, Epoxy Iron Repair

-

Application:

-

Fast Fix

-

Shelf life:

-

12 Months

-

Ratio:

-

1(A):1(B)

-

Model:

-

Iron,steel,aluminium,copper

-

Tensile strength(Mpa):

-

39

-

Compressive strength (Mpa):

-

125

-

shear strength(Mpa):

-

19

-

Hardness:

-

80

-

deliver time:

-

3-7 working days

Quick Details

-

CAS No.:

-

38891-59-7

-

Other Names:

-

Iron Putty

-

MF:

-

C21H23CIFNO2

-

EINECS No.:

-

38891-59-7

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HiGlue

-

Model Number:

-

111

-

Type:

-

Epoxy Iron Repair, Epoxy Iron Repair

-

Application:

-

Fast Fix

-

Shelf life:

-

12 Months

-

Ratio:

-

1(A):1(B)

-

Model:

-

Iron,steel,aluminium,copper

-

Tensile strength(Mpa):

-

39

-

Compressive strength (Mpa):

-

125

-

shear strength(Mpa):

-

19

-

Hardness:

-

80

-

deliver time:

-

3-7 working days

Products Description

50ml Great Power Magic Epoxy Welding Super Glue Repair Agent

This product is mainly used for iron, steel castings filled blisters, pores or cracks, casting defects, high cured hardness, can be used at 100-150 C.

General performance:

A gray mud-like paste

B white paste body

Volume ratio: A: B = 1:1

Curing performance:

Hardness: 80 (Shore-D)

Shear strength: 18 (25°C)

Full cure time: 12 hours (25°C)

Bonding process:

1. First, identify needed repairs at the clean, no stains.

2. with a file, sandpaper and other tools to deal with a flat surface.

3. Press A, B component volume ratio 1:1 full tone evenly coated on the object to be repaired. Can be a variety of processing completed 24 hours after the four bonding.

Note :

The adhesive has a mixed use of 1 hour or so. Shall be in accordance with the ratio of the A, B components are mixed before use,

so that no color mixture can be used. With use namely, run out of time.

Storage conditions

In the temperature range of 15 ~ 28 C preservation, preservation period of up to 24 months.

Specification

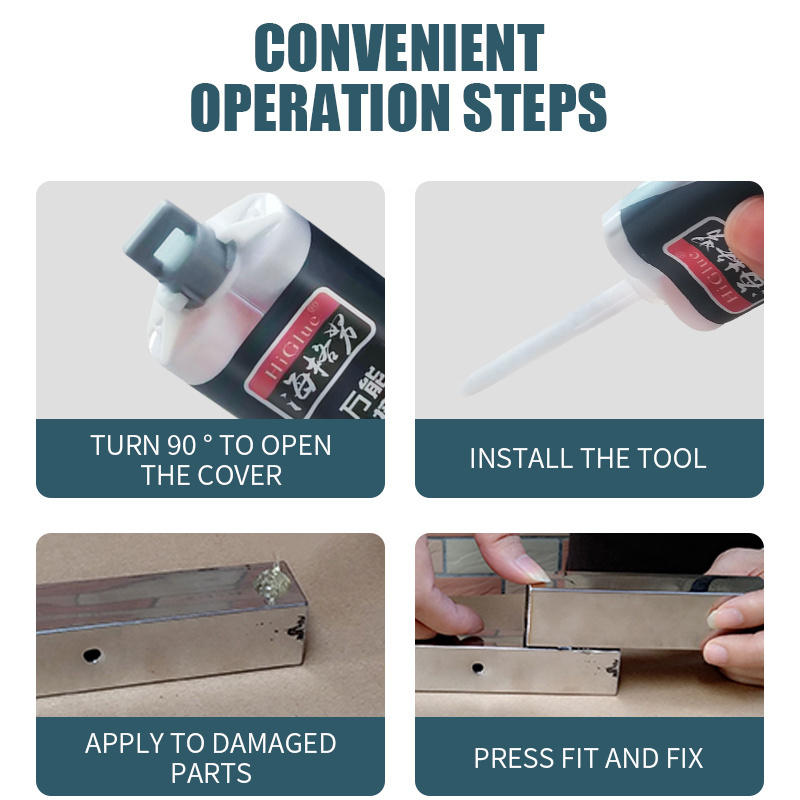

How To Use

1. First find out the area to be repaired and clean it without stains.

2. Use files, sandpaper and other tools to smooth the surface

3. According to the volume ratio of A and B components at a ratio of 1:1, fully adjust it evenly, and apply it on the object to be repaired

4. Various processing can be carried out 24 hours after the bonding is completed.

2. Use files, sandpaper and other tools to smooth the surface

3. According to the volume ratio of A and B components at a ratio of 1:1, fully adjust it evenly, and apply it on the object to be repaired

4. Various processing can be carried out 24 hours after the bonding is completed.

Precautions:

The glue has a use period of 1 hour after mixing. Before application, the A and B components should be mixed evenly according to the proportion, so that the mixture can be used without color difference. Dispense ready to use, use up once.

The glue has a use period of 1 hour after mixing. Before application, the A and B components should be mixed evenly according to the proportion, so that the mixture can be used without color difference. Dispense ready to use, use up once.

Application

Mainly used for iron and steel casting, sand holes and pores, and filling of casting defects such as cracks. It can be used to repair fuel tanks, plumbing and a whole lot more.

Packing & Shipping

Our Certifications

Hot Searches