Oscillating Tool Cutting Controller:

— CCD

— Software: TroSCCDCut

— System Requirement: WinXP、Win7 Win10

— Accurate positioning cutting

— Subtle stretching and auto compensation

— Auto recognition cutting

— Real-time contour recognition

— Compatible with various graphic design software

- Product Details

- {{item.text}}

Quick Details

-

Graphic Format Supported:

-

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

-

Cooling Mode:

-

WATER COOLING

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RUMAN

-

Dimension(L*W*H):

-

230*210*160cm

-

Weight (KG):

-

450 KG

-

Product name:

-

Co2 Laser Cutting Machine

-

Keyword:

-

fabric rolling cutting machine

-

Control system:

-

Ruida trocen

-

Laser power:

-

80w/100w/130w/150w

-

Function:

-

Cutting Engraving Non-metal Materials

-

Working table:

-

chain rolling table

-

Laser source:

-

co2 laser tube

-

Model:

-

1610/1810/1812

Quick Details

-

Engraving Area:

-

1600mm*1000mm

-

Laser Type:

-

CO2

-

Engraving Speed:

-

0-1500mm/s

-

Graphic Format Supported:

-

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

-

Cooling Mode:

-

WATER COOLING

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RUMAN

-

Dimension(L*W*H):

-

230*210*160cm

-

Weight (KG):

-

450 KG

-

Product name:

-

Co2 Laser Cutting Machine

-

Keyword:

-

fabric rolling cutting machine

-

Control system:

-

Ruida trocen

-

Laser power:

-

80w/100w/130w/150w

-

Function:

-

Cutting Engraving Non-metal Materials

-

Working table:

-

chain rolling table

-

Laser source:

-

co2 laser tube

-

Model:

-

1610/1810/1812

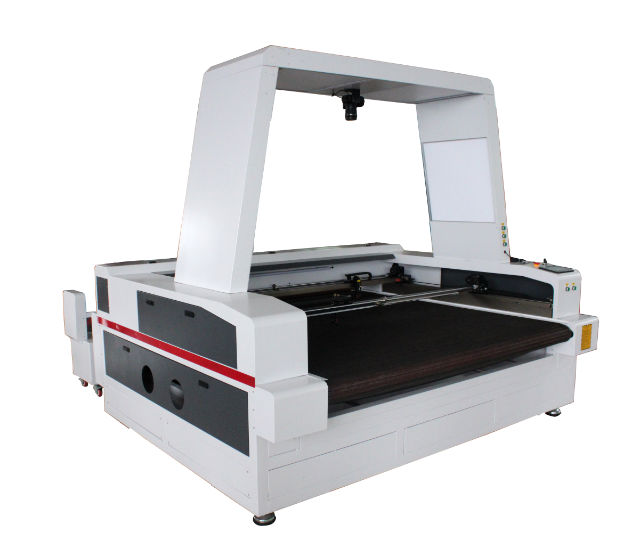

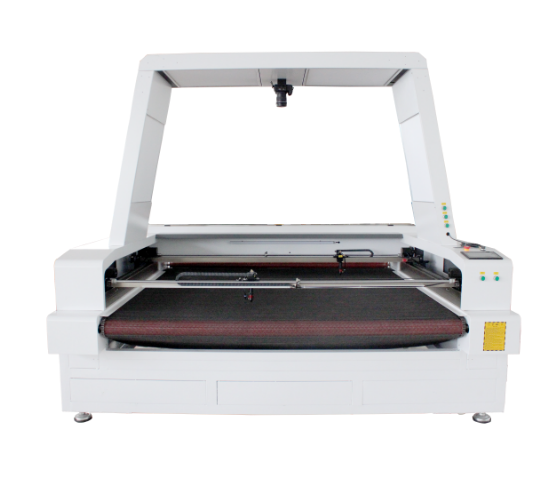

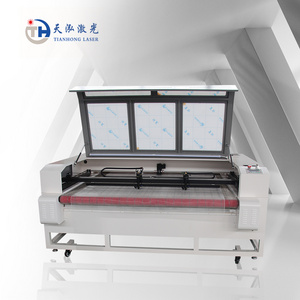

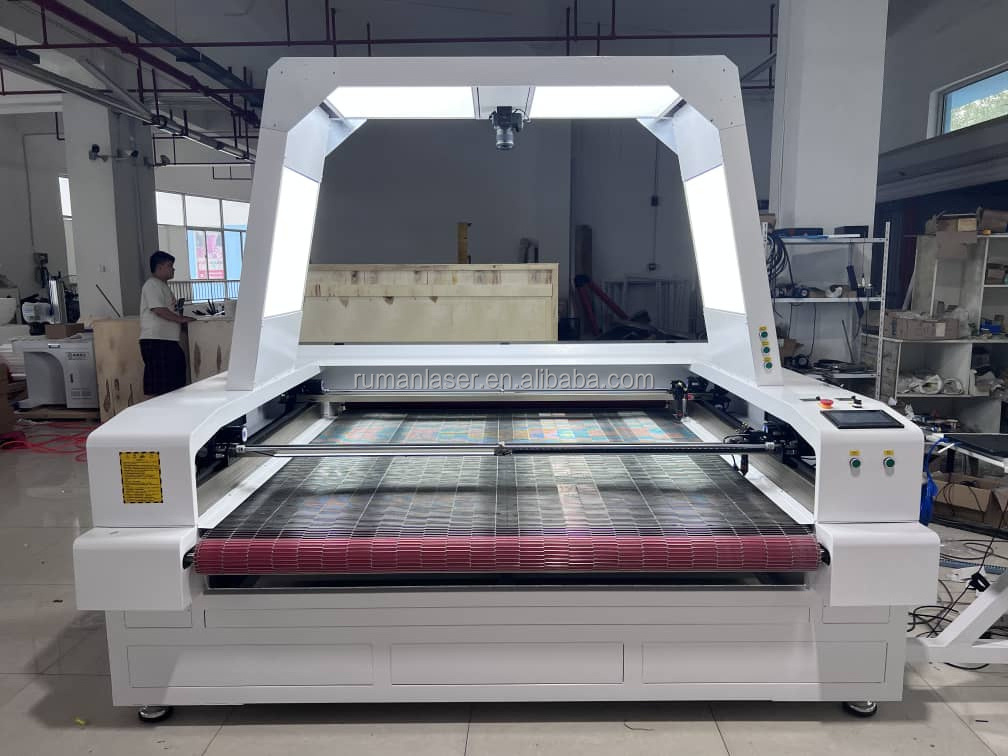

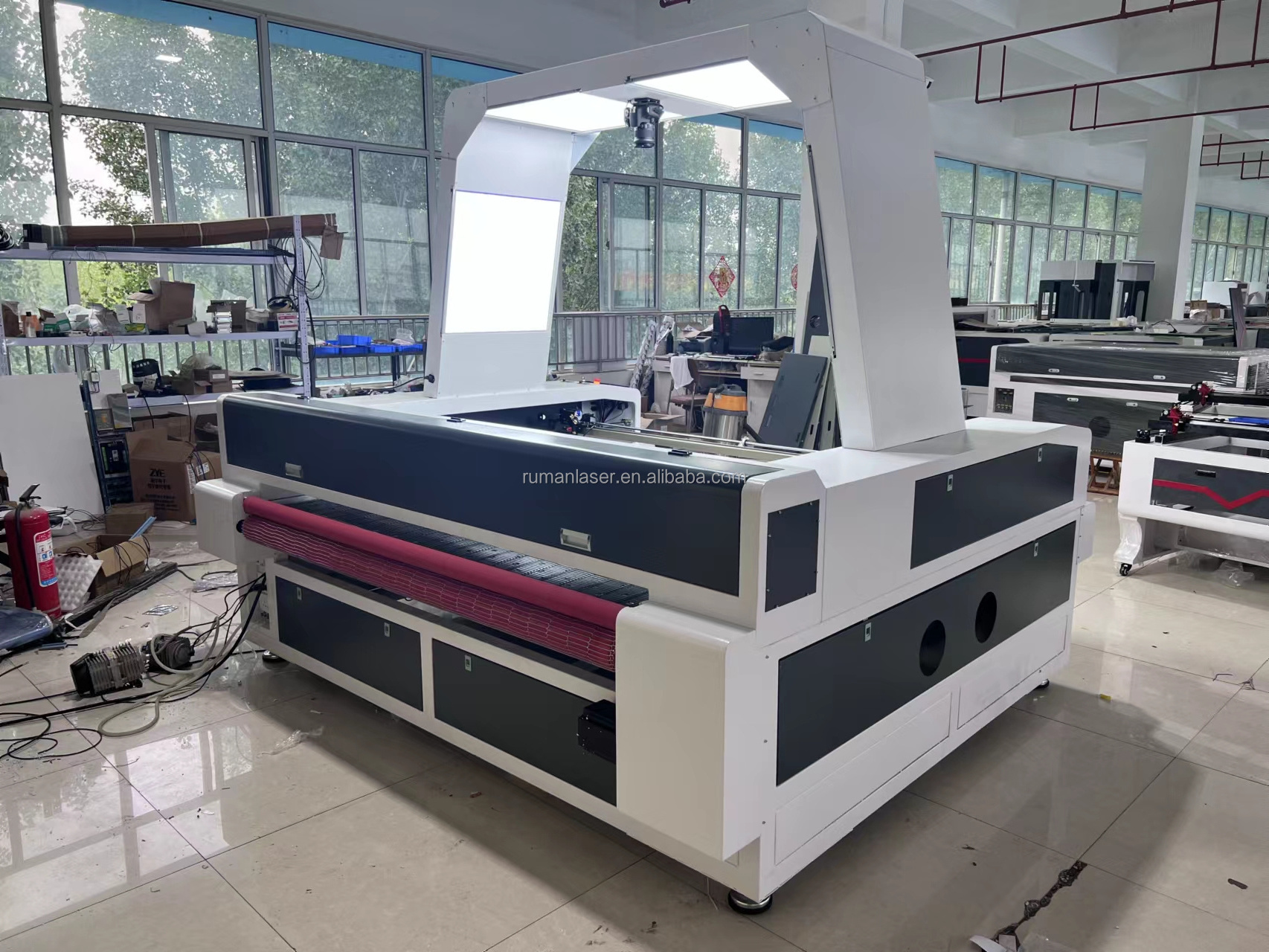

RUMAN Vision Laser Cutting Machine Solution

Laser cutting technology is ideal enough to smoothly and effectively cut many kinds of materials without causing it any harm overall. The Camera Vision Laser Cutting Machine is the laser cutter combined with the advanced large vision software system of the Ruman laser. It can automatically recognize the contour of the printed or embroidered fabrics, leather, and other flexible materials and then cut with super high accuracy

RUMAN Laser’s vision laser cutting machine with a top Canon camera can realize position cutting of printed or

embroidered materials with super high precision.

* Optional auto feeding conveyor systems can at least double the production by saving the pattern pick-up time and fabric layout time as well as saving your labors.

* Optional camera system can realize high accuracy positioning cutting with excellent cutting speed.

* Strong vision system with integrated multifunction auto edge tracking, auto contour extraction, and template matching modes.

* Auto-correction for distortion and stretching, and great cutting edge with the capacity of increasing its strength to 40 times.

T shirts making 1810 scan camera auto-feeding cloth laser cutting machine textile laser cutting machine price

|

Working Area

|

1600MM*1200MM/1800*1200mm

|

Software

|

Trocen cutting system

|

|

Laser Type

|

Glass CO2 Laser Tube

|

Working Speed

|

<1000 MM/S

|

|

Laser Power

|

80/100/130/150W

|

Power Supply Requirements

|

AC220V±5% 50Hz/60Hz 1Phase

|

|

Heads of Laser

|

two Head

|

Format Supported

|

AI\BMP\PLT\DXF\DST

|

|

Dimensions machine

|

2.18*2.4*1.50M

|

Positioning Accuracy

|

±0.1MM

|

|

Gross Weight

|

500KG

|

Operating Temperature

|

minus 10℃~45℃

|

|

Motion System

|

Leadshine Motor

|

Operating Humidity

|

5-95%

|

|

Cooling System

|

5200 Industrial Water Chiller

|

Total Power

|

<1.5KW (Excluding exhauster)

|

Laser Controller:

TL5200PRO

Motion system

More Stable Triangle Structure Design

The triangle machine structure design means more cost for us, but more benefits for you. Bigger waste collection space, better

smoke exhausting effect, and more stable for the conveyor chain belt’s motion.

The triangle machine structure design means more cost for us, but more benefits for you. Bigger waste collection space, better

smoke exhausting effect, and more stable for the conveyor chain belt’s motion.

CANNON CAMERA

HIgh speed and Japan CANNON camera scanning head

Chain rolling table.

RUMAN LASER is equipped with a chain conveyor belt, which can auto-feed the roll material right after the laser cutting

process.Together with the optional active feeder, the operator only needs to take care of the cut pattern pick-up job.

process.Together with the optional active feeder, the operator only needs to take care of the cut pattern pick-up job.

APPLICATION

laser engraving machine can create a tactile and haptic effect on the fabric. Whether polyester extravagantly-shaped cuts or engraving felt cuts, a laser machine can propose amazing designs on textile processing

Plain Felt Laser Cutter

* Cut plain felt fabrics into sizes and shapes efficiently

* Achieve incredible finish and edges

* Non-contact process is gentle on the plain felt material

* Finest details and patterns cuts with great attention

* Cut plain felt fabrics into sizes and shapes efficiently

* Achieve incredible finish and edges

* Non-contact process is gentle on the plain felt material

* Finest details and patterns cuts with great attention

Together with RUMAN laser camera system and vision software, it can position cut out the printed patterns with super high speed and accuracy, the smart software is very easy to operate

Leather Laser Technology Advantages

* A consistent high cutting speed for increased productivity

* Precise, clean, perfectly sealed edges and reliable cut

* Incredibly fast, eliminates warping

* A consistent high cutting speed for increased productivity

* Precise, clean, perfectly sealed edges and reliable cut

* Incredibly fast, eliminates warping

* High precision and high-speed leather engraver machine

* Precise process, allows you to create complex patterns

* Controlled by computer software, beams are powerful enough

* Perfect cutting and engraving

* Precise process, allows you to create complex patterns

* Controlled by computer software, beams are powerful enough

* Perfect cutting and engraving

* Together with the camera system to guarantee high-precision cutting of printed leather

* Quality results without even having contact with the PU leather surface

* No maintenance, low-cost production

* You can create and print and cut any design or pattern

* Quality results without even having contact with the PU leather surface

* No maintenance, low-cost production

* You can create and print and cut any design or pattern

* Camera system and vision software applied to conduct edge cutting of embroidered leather designs

* Automatic CNC laser cutting machine with CO2 laser tube to etch, engrave and cut

* Give full play to motion control performance and laser processing .

* Automatic CNC laser cutting machine with CO2 laser tube to etch, engrave and cut

* Give full play to motion control performance and laser processing .

FAQ

Q1. How to get the most suitable machine and best price

As we may know,the different type of CNC machine apply to the different material,and the different model apply to the different

material.Thus,Please tell us what's material you want to cutting or engraving ?And what's MAX size of carved material ?Then we wil

recommand the most suitable model and the best price for you.

Q2. If we don't know how to use the machine,can you teach us?

Yes, We will send you manual and guide vedio in English, it can teach you how to operate the machine. If you still can not learn

how to use it, we can help you by "Teamviewer" online helpsoftware.Or we can talk by phone, email or skype

Q3.How long is the delivery time?

For standard machines, it would be 3-5 days; For non-standard machines and customized machines according to client's specific

requirements, it would be 7 to 10 days.

Q4. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The

complete machine will be tested to make sure they can work very well before being out of factory.

Our machine passed CE Certificate, meet European and American standard, were exported to more than 100 Countries.

Q5. Do you arrange shipment for the machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange

shipment by themselves or their agents.

As we may know,the different type of CNC machine apply to the different material,and the different model apply to the different

material.Thus,Please tell us what's material you want to cutting or engraving ?And what's MAX size of carved material ?Then we wil

recommand the most suitable model and the best price for you.

Q2. If we don't know how to use the machine,can you teach us?

Yes, We will send you manual and guide vedio in English, it can teach you how to operate the machine. If you still can not learn

how to use it, we can help you by "Teamviewer" online helpsoftware.Or we can talk by phone, email or skype

Q3.How long is the delivery time?

For standard machines, it would be 3-5 days; For non-standard machines and customized machines according to client's specific

requirements, it would be 7 to 10 days.

Q4. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The

complete machine will be tested to make sure they can work very well before being out of factory.

Our machine passed CE Certificate, meet European and American standard, were exported to more than 100 Countries.

Q5. Do you arrange shipment for the machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange

shipment by themselves or their agents.

Hot Searches