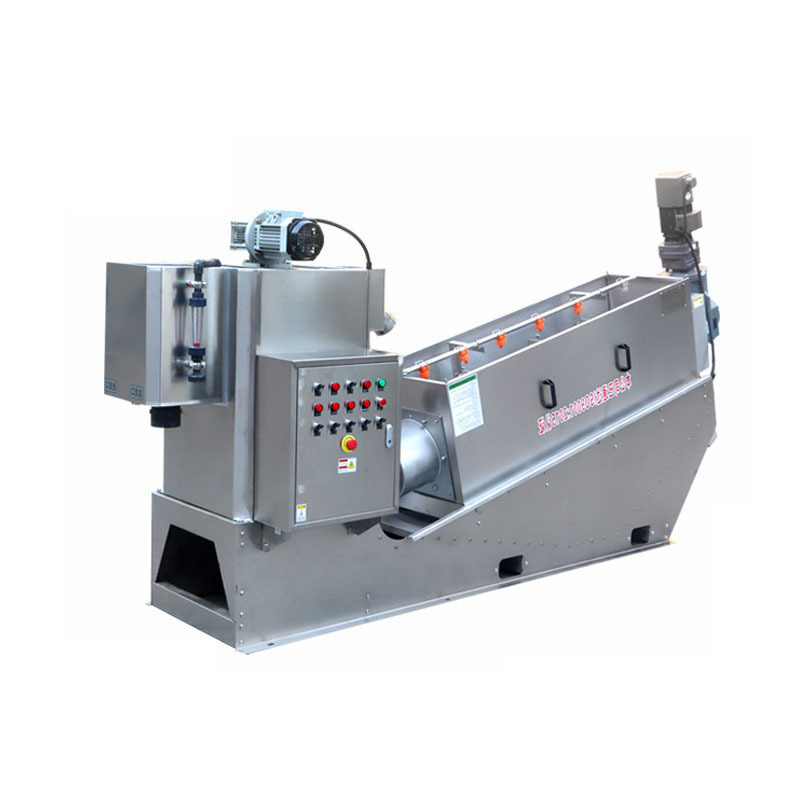

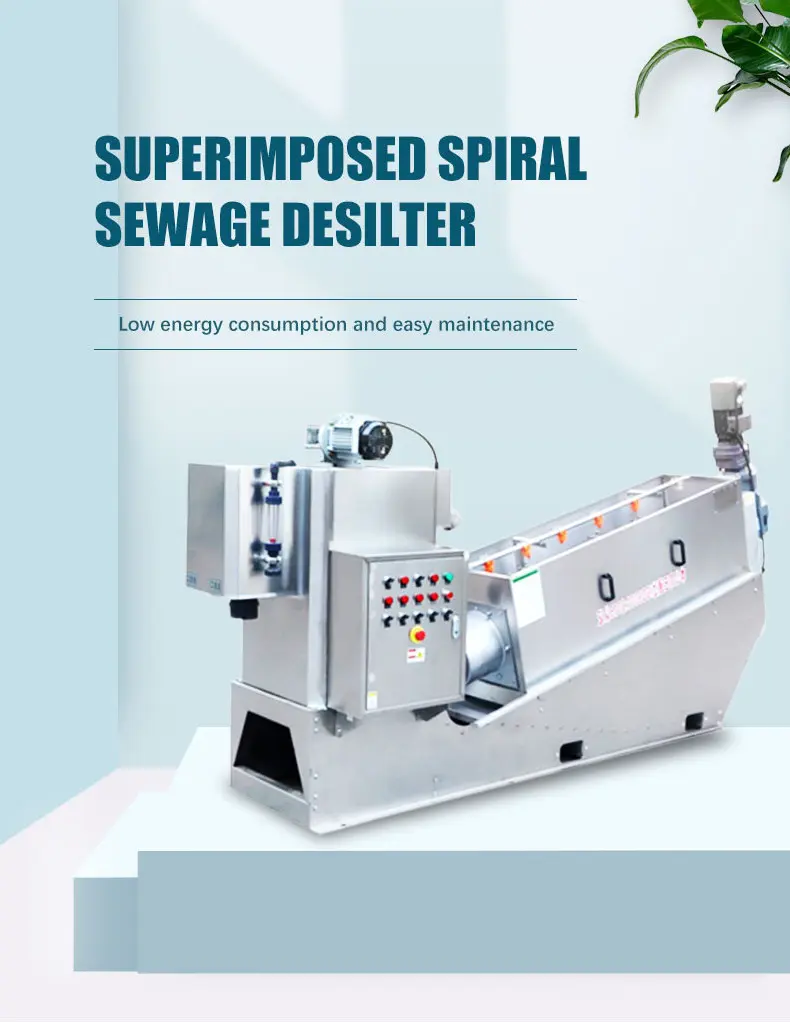

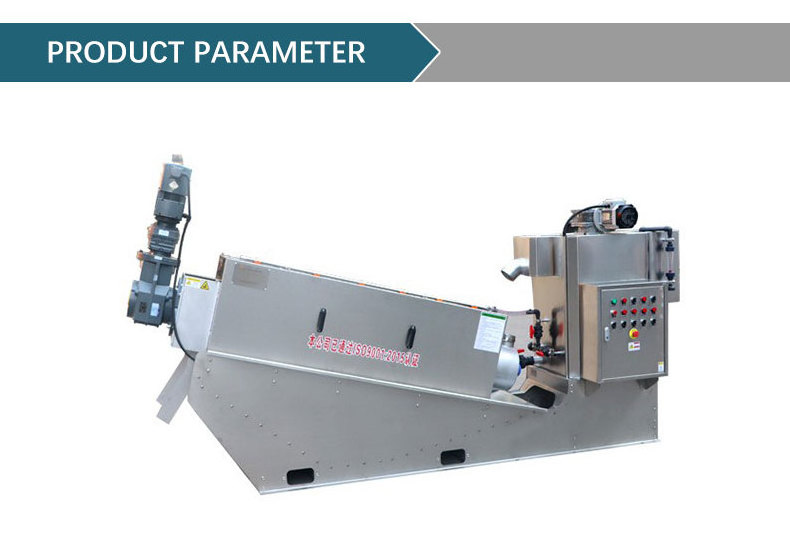

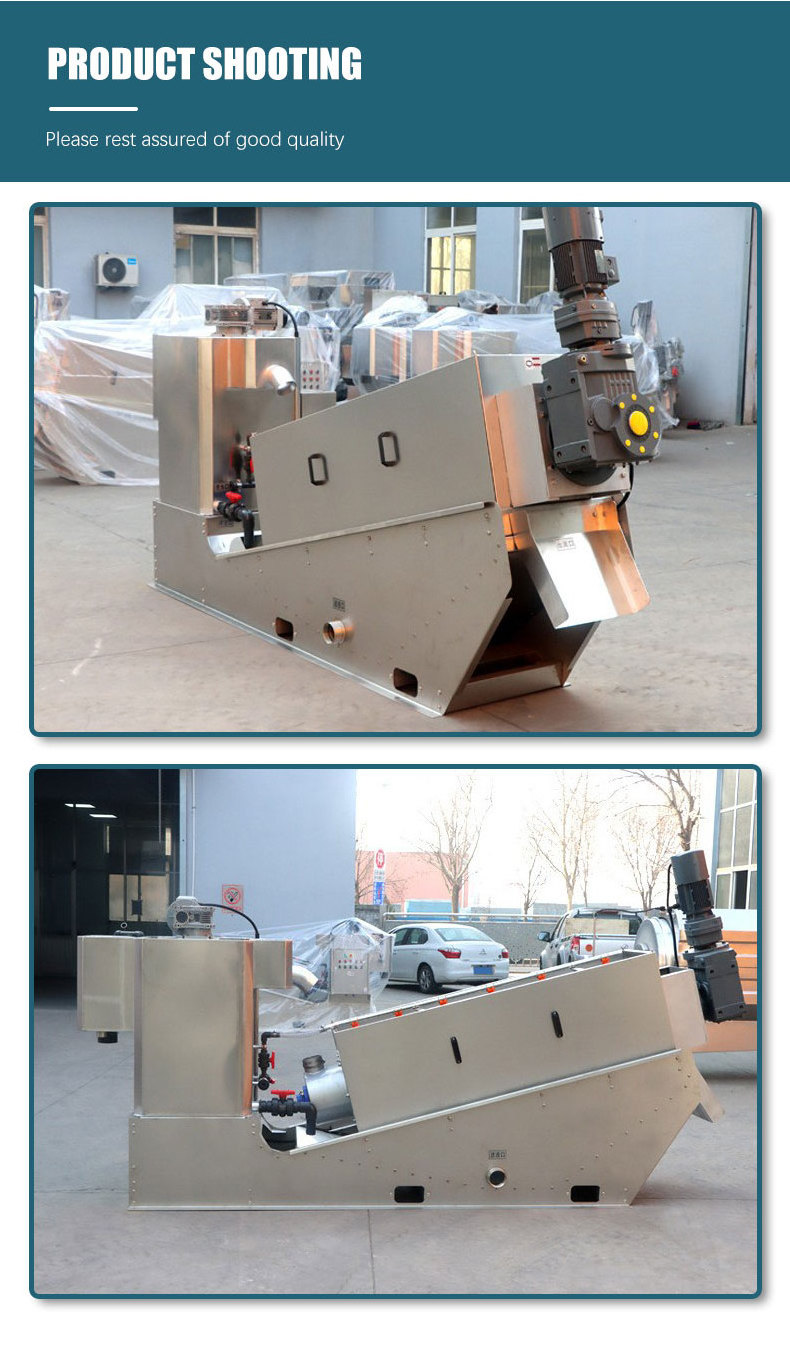

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5kw

-

Weight:

-

560 kg

-

Plate and frame filter press:

-

Normal Filter Plate

-

Keywords:

-

Liquid Filter Machine

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220v

-

Power:

-

7.5kw

-

Weight:

-

560 kg

-

Plate and frame filter press:

-

Normal Filter Plate

-

Keywords:

-

Liquid Filter Machine

|

MODEL

|

PROCESSING

|

EXTERNAL DIMENSION(mm)

|

POWER(kw)

|

MAXIMUM DOSAGE(L/h)

|

MATERIAL

|

|

JSYDL-1013

|

0.2-0.3m³/h

|

2200*700*1300mm

|

1.12

|

60L/h

|

304/POM

|

|

JSYDL-1023

|

0.4-1.3m³/h

|

2200*300*1400mm

|

1.87

|

120L/h

|

304/POM

|

|

JSYDL-1313

|

0.2-0.5m³/h

|

2200*700*1300mm

|

1.12

|

90L/h

|

304/POM

|

|

JSYDL-2013

|

0.4-1.5m³/h

|

2900*300*1500mm

|

1.3

|

120L/h

|

304/POM

|

|

JSYDL-2023

|

0.8-3m³/h

|

3000*1100*1500mm

|

2.05

|

480L/h

|

304/POM

|

|

JSYDL-3013

|

1-3m³/h

|

3400*300*1800mm

|

1.65

|

360L/h

|

304/POM

|

|

JSYDL-3023

|

2-6m³/h

|

3600*1300*1800mm

|

2.2

|

720L/h

|

304/POM

|

|

JSYDL-3033

|

3-9m³/h

|

3900*1700*1800mm

|

4.4

|

1080L/h

|

304/POM

|

|

JSYDL-4013

|

5-9m³/h

|

4300*1100*1900mm

|

2.2

|

700L/h

|

304/POM

|

|

JSYDL-4023

|

10-18m³/h

|

4300*1400*1900mm

|

3.3

|

1400L/h

|

304/POM

|

|

JSYDL-4033

|

15-27m³/h

|

4500*2000*1950mm

|

4.4

|

2100L/h

|

304/POM

|

|

JSYDL-4043

|

20-36m³/h

|

4400*2400*1950mm

|

6.6

|

4000L/h

|

304/POM

|

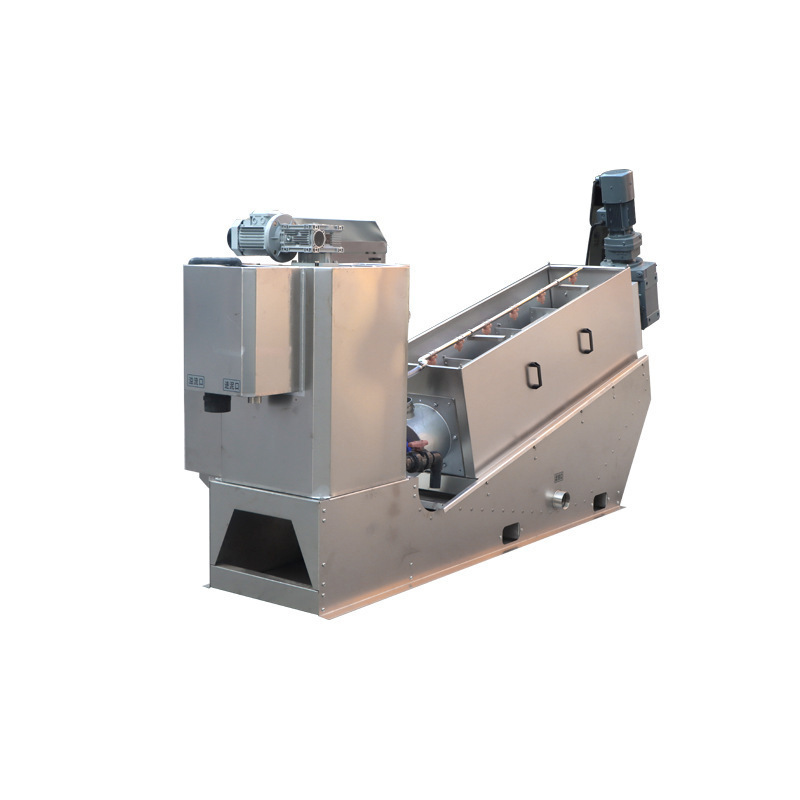

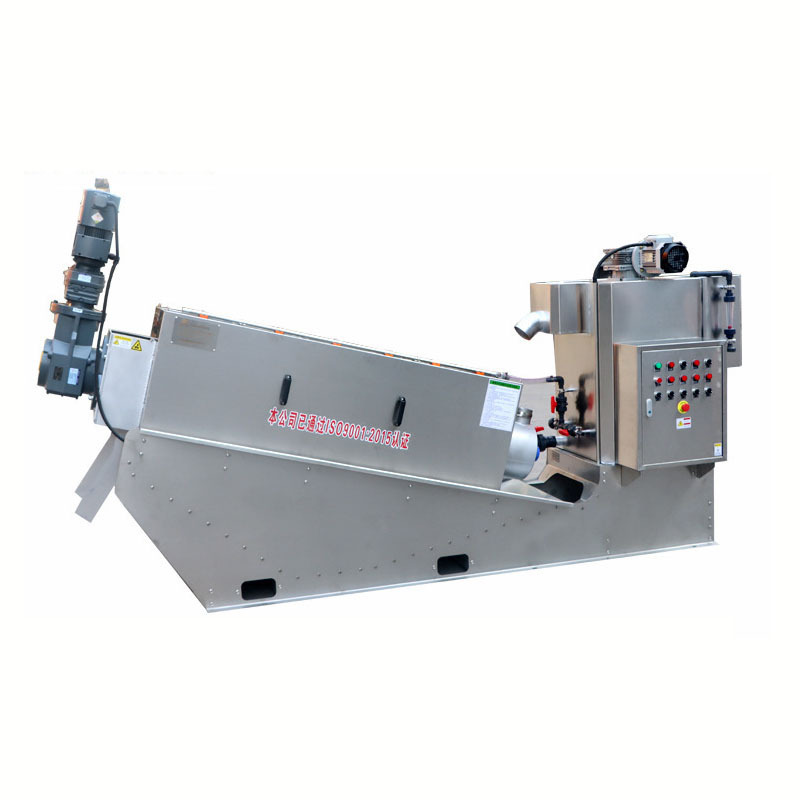

When the equipment is running

,

the sludge enters the filter from the feed port and is pushed to the discharge port by the spiral shaft rotating plate. As the pitch between the spiral shaft rotating plates is gradually reduced, the pressure on the sludge also increases, and the water begins to dehydrate under the action of pressure difference, and the water flows out from the filter gap between the fixed ring and the movable ring plate. Meanwhile, the equipment relies on the self-cleaning function between the fixed plate and the movable plate. The filter gap is cleaned to prevent clogging, and the mud cake is discharged from the discharge port under the push of the spiral shaft after sufficient dehydration. According to the different properties of sludge, the company has developed a targeted machine, which is more practical in structure and lower in use cost.

1.Metering tank

The sludge is transported to the metering tank through the sludge conveying pump, and the excess part is returned to the sludge storage tank from the return pipe

2.Flocculation mixing tank

The measured sludge is mixed fully with the injected polymer flocculant in the flocculation mixing tank to form a good alum flower.

3.Disontology

After the sludge enters the dewatering body through the mud inlet, gravity concentration occurs instantaneously in the concentration part of the front section, and most of the filtrate is discharged. In the dewatering part, it is fully dehydrated due to the continuous rise of the pressure in the inner cavity. The dewatering body of the sludge thickener does not contain a dewatering part.

4.Sludge outlet/concentrated sludge outlet

The back pressure plate arranged in the mud outlet produces a blocking force in the opposite direction, thus further increasing the pressure in the body cavity, making the sludge more fully dehydrated and discharged from the mud outlet in the form of mud cake. The sludge thickener discharged through the sludge outlet is the concentrated sludge. The sludge thickener is not provided with a back pressure plate on the sludge outlet side

Jiangsu Changzhou Senjie Environmental Protection Equipment Co., Ltd.

is a professional waste water treatment equipment research and development, production, installation, after-sales service as one

of the integrated environmental pollution control high-tech enterprises. The company's products are suitable for environmental

management in furniture industry, wood products industry, footwear industry, chemical industry, feed mill, electronics industry

and other industries. According to the different needs of customers, we can design environmental governance programs that make

customers satisfied. So far, several enterprises have solved the problem of environmental pollution.

|

1. Q: Can you provide us with detailed drawings?

|

|

|

|

|

||||

|

Yes, we can provide you with drawings after advance payment.

|

|

|

|

|

||||

|

2. Q: Are you a manufacturer or a trader?

|

|

|

|

|

||||

|

We are a professional and experienced manufacturer located in Changzhou, Jiangsu Province.

|

|

|

|

|

||||

|

3. Q: Can you accept OEM?

|

|

|

|

|

||||

|

Yes, we can produce the machinery exactly according to your design standards.

|

|

|

|

|

||||

|

4. Q: What about delivery time?

|

|

|

|

|

||||

|

Usually 10-20 working days after prepayment, we promise to ship as soon as possible.

|

|

|

|

|

||||

|

5. Q: How do we ensure quality?

|

|

|

|

|

||||

|

We always send drawings for your confirmation prior to production and always carry out a final check before shipping.

|

|

|

|

|

||||

Hot Searches