Connect 8bar to drive compressed air, turn on the booster system switch to start boosting, when the pressure increases to 40bar, the booster system will automatically stop working, install the standard meter and the check pressure gauge.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ODMT

-

Model Number:

-

HLTD Series

-

Material:

-

none

-

Size:

-

1500*800*2000mm

-

Weight:

-

300kg

-

color:

-

White

-

Appllication:

-

all the pressure gauges

-

Application:

-

test for pressure guage

-

Name:

-

pressure gauge tester

Quick Details

-

Type:

-

Pressure Calibrators

-

Warranty:

-

1 years

-

Place of Origin:

-

Shandong, China, Shandong China

-

Brand Name:

-

ODMT

-

Model Number:

-

HLTD Series

-

Material:

-

none

-

Size:

-

1500*800*2000mm

-

Weight:

-

300kg

-

color:

-

White

-

Appllication:

-

all the pressure gauges

-

Application:

-

test for pressure guage

-

Name:

-

pressure gauge tester

Product Description

Specification

|

item

|

value

|

|

Warranty

|

1 year

|

|

Customized support

|

OEM

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

ODMT

|

|

Model Number

|

MFCG

|

|

Product Name

|

pressure gauge test bench

|

|

Warranty

|

1 year

|

|

Thread

|

BSP1/2

|

|

Pressure range

|

0.1~0~100Mpa

|

|

Material

|

Carbon Steel

|

|

Accuracy

|

0.5%

|

|

Connection

|

NPT

|

|

Application

|

Hydraulic Industries

|

|

Certification

|

CE cerification

|

|

Medium

|

water

|

Introduction

MFCG series pressure gauge calibration table is applicable for testing spring tubes (C-type tube, coil spring tube, spiral tube), etc. The calibration pressure of pneumatic calibration table is up to 15Mpa and that of hydraulic calibration table is up to 250Mpa.

When the negative pressure gauge needs to be tested, the vacuum pump is turned on, a certain degree of vacuum is drawn, and the vacuum check valve is opened to start the calibration;

When testing the positive pressure pressure gauge, first adjust the pressure of the pressure reducing valve to 0, then gradually increase the pressure. According to the range test pressure gauge of the table calibration table, compare with the standard table, and determine the accuracy of the pressure gauge after manual recording.

|

Tested object

|

Pressure gauge

|

|

Features

|

Calibration test

|

|

Related standards

|

GB/T 1226-2001

|

|

Test medium

|

Gas

|

|

Test Pressure

|

0~100bar.

The pressure test uses the compressed air provided by the customer to drive the gas supercharger to increase the pressure, and the pressure is increased by 15MPa, and the precision pressure reducer is output after the pressure is adjusted. The pressure is used for the test. |

|

Pressure testing accuracy

|

±1%F.S

|

|

Pressure control accuracy

|

±2%F.S

|

|

Drive pressure

|

3-8bar

|

|

Medium temperature

|

Room temperature +10-80℃

|

|

Ambient temperature

|

Room temperature

|

|

Simultaneous test pieces

|

2 pieces

|

|

Control

|

Manual control

|

|

Dimensions

|

1300mm*600mm*1100mm

|

|

Wooden Cases

|

Export standard fumigation wooden cases

|

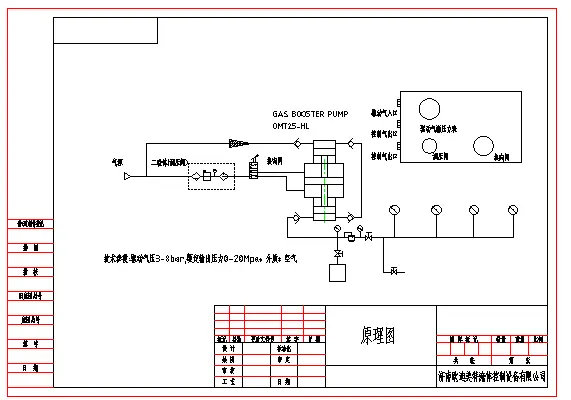

Schematic Diagram of Control Part

Details Images

Test Bench Structure

|

The main components

|

Detailed composition

|

|

power system

|

2-8bar compressed air (customer-supplied), clean water (customer-supplied), booster pump.

Liquid test: The test air source is pressurized by the built-in pneumatic booster pump for testing. |

|

Drive gas source treatment

|

Drive the air supply line to the front end of the supercharger with a duplex./Can be used for coarse filtration and pressure

regulation of pipeline gas pressure |

|

Test cabinet

|

Ordinary carbon steel profile welding./Surface rust and spray treatment

|

|

Booster system

|

Booster pump, high pressure needle valve, precision pressure regulating valve, etc.for high pressure gas testing

|

|

Test piece installation

|

Threaded, the joint is directly attached to the test bench panel

|

Hot Searches