- Product Details

- {{item.text}}

Quick Details

-

Rated Voltage:

-

24kv

-

Tensile Strength:

-

340MPa

-

Color:

-

green, yellow, black,white

-

Product name:

-

Epoxy glass Sheet

-

Certification:

-

Rhos

-

Thickness:

-

0.1-100mm

-

Sample:

-

Sample Avaliable

-

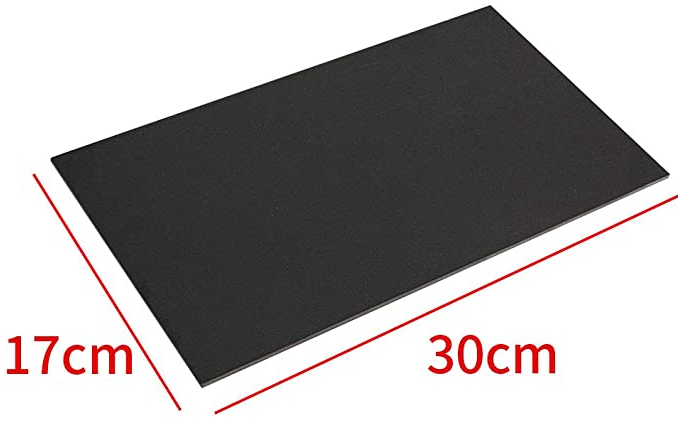

Size:

-

1020X2040mm, 1220x2440mm, 1020x1220mm,1200*3100mm,1220*2700mm

-

MOQ:

-

500KG

-

Density:

-

2 g/cm3

-

Delivery time:

-

5-20 days

-

material:

-

epoxy resin +fiberglass cloth

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Leadwin

-

Model Number:

-

epoxy glass fiber sheet

-

Rated Voltage:

-

24kv

-

Tensile Strength:

-

340MPa

-

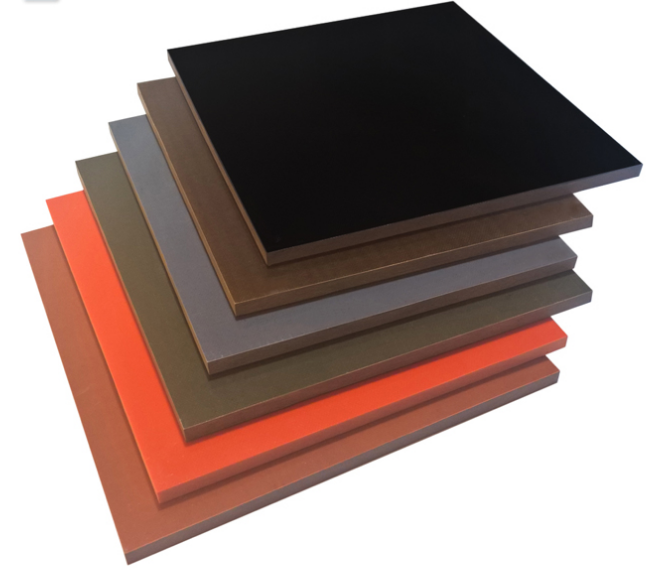

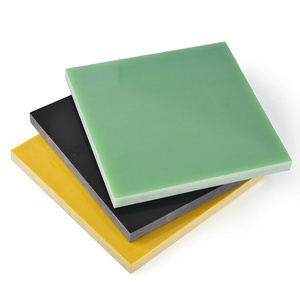

Color:

-

green, yellow, black,white

-

Product name:

-

Epoxy glass Sheet

-

Certification:

-

Rhos

-

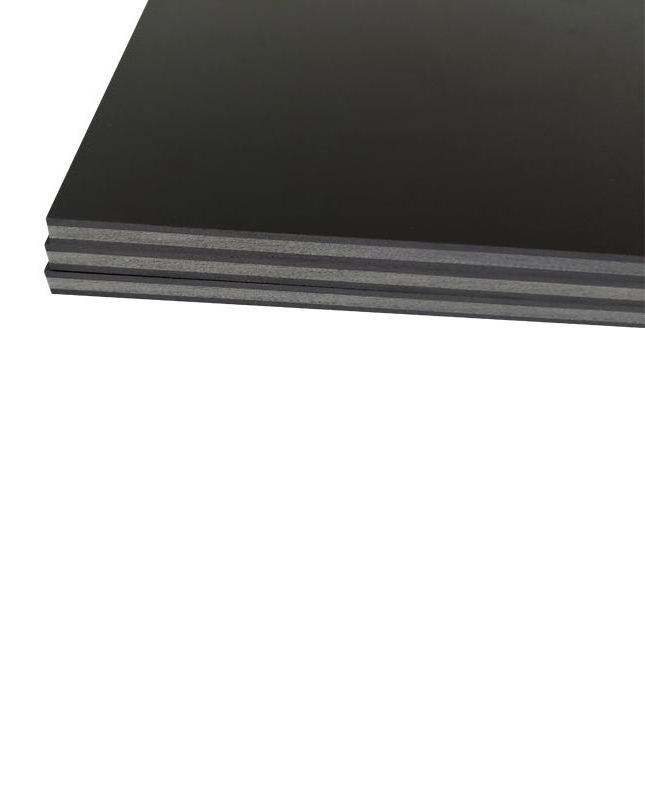

Thickness:

-

0.1-100mm

-

Sample:

-

Sample Avaliable

-

Size:

-

1020X2040mm, 1220x2440mm, 1020x1220mm,1200*3100mm,1220*2700mm

-

MOQ:

-

500KG

-

Density:

-

2 g/cm3

-

Delivery time:

-

5-20 days

-

material:

-

epoxy resin +fiberglass cloth

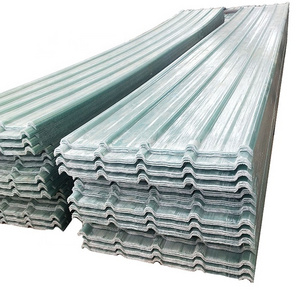

Product Introduction

NO.1 Product Introduction

Epoxy Glass Fiber Sheet is a NEMA grade designation for glass-reinforced epoxy laminate materials.

G10 fiberglass plate

(

EPGC 201

)

, made of E-glass fabric impregnated with epoxy resin by processing under high temprature and pressure.

G10 fiberglass plate is a popular and versatile high-pressure thermal plastic laminate grade with good strength to weight ratios.

| International Standard | IEC60893 | EPGC 203 | EPGC204 | ||

| DIN 7735 | Hgw2372.4 | Hgw2372.2 | |||

| NEMA | G11 | FR5 | |||

| Properties | Test Method | Unit | Value | Value | |

| Physical | Density | g/cm 3 | 1.9-2.0 | 1.9-2.0 | |

| properties | Colour | Green | Yellow/Green | ||

| Water absorption | E-24/50+D-24/23 | % | 0.07-0.16 | 0.07-0.16 | |

| Mechanical | Flexural Strength | A | Mpa | 385-490 | 385-490 |

| properties | Flexural Strength | 150℃ | Mpa | 210 | 210 |

| Impact Strength | A | KJ/M 2 | 33 | 33 | |

| Rockwell Hardness | A | M | 110 | 110 | |

| Compressive | A | Mpa | 280-330 | 280-330 | |

| Strength | A | Mpa | 180-230 | 180-230 | |

| Electrical | Electrical | C-96/20/65(in 90℃ oil) | KV/mm | ≥14 | ≥14 |

| Properties | Strength | C-0.5/90(in 90℃ oil) | KV | 40 | 40 |

| Volume Resistivity | C-96/20/65 | Ω.cm | ≥10 11 | ≥10 11 | |

| C-96/20/65+C-96/40/90 | Ω.cm | ≥10 10 | ≥10 10 | ||

| Surface Resistivity | C-96/20/65 | Ω | ≥10 10 | ≥10 10 | |

| C-96/20/65+C-96/40/90 | Ω | ≥10 10 | ≥10 10 | ||

| Dielectric Constant | C-96/20/65 | 4.0-5.0 | 4.0-5.0 | ||

| 1MHz | C-96/20/65+D-48/50 | 4.0-5.5 | 4.0-5.5 | ||

| Disspation Factor | C-96/20/65 | 0.03-0.04 | 0.03-0.04 | ||

| 1MHz | C-96/20/65+D-48/50 | 0.04-0.05 | 0.04-0.05 | ||

| Arc Resisitance | C-96/20/65 | Sec | 130-140 | 130-140 | |

| Flame | UL Subject 94 | A | HB | V-0 | |

| Resistance | Smoke Density 90 | ASTM-E 662 | 1 | 1 | |

| Toxicant Content | ASTM-E 663 | Low | Low | ||

| Others | Acetone Resisitance | boiled | Min | 30(ok) | 30(ok) |

| Punchability( 3mm) | A | Good | Good | ||

Hot Searches