- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CP-30

-

Model:

-

CP-30

-

Max Load Weight:

-

30kg

-

Wire diameter:

-

0.6-5mm

-

Feeding speed:

-

Max 2.5m/s

-

Power Supply:

-

220V

-

Power:

-

120W

-

Dimensions:

-

450*430*760 mm

-

Weight:

-

58kg

Quick Details

-

Use:

-

feeder wire

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

Wejion

-

Model Number:

-

CP-30

-

Model:

-

CP-30

-

Max Load Weight:

-

30kg

-

Wire diameter:

-

0.6-5mm

-

Feeding speed:

-

Max 2.5m/s

-

Power Supply:

-

220V

-

Power:

-

120W

-

Dimensions:

-

450*430*760 mm

-

Weight:

-

58kg

Product Description

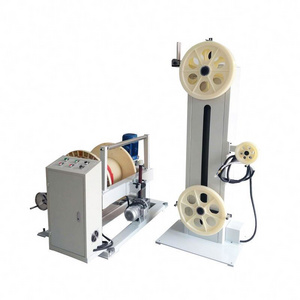

CP-30 Cable Prefeeder

Parameters

|

Model

|

CP-30

|

|

Max Load Weight

|

30kg

|

|

Wire diameter

|

0.6-5mm

|

|

Feeding speed

|

Max 2.5m/s

|

|

Power Supply

|

220V

|

|

Power

|

120W

|

|

Dimensions

|

450*430*760 mm

|

|

Weight

|

58kg

|

CP-30

Features:

Built-in 2 sets of motors and multiple sets of sensors, the middle section is equipped with a wire straightener, which can automatically straighten the wire at the same time as the wire is fed. It can easily respond to the typical intermittent starting and stopping actions associated with automatic wire processing machines.

Hot Sell Products

A. Small One Core Stripping Machine:

C. Multi-Core Wire Stripping Machine:

Packing

Company Introduction

Kunshan Weijiang Automation Equipment Co., Ltd

is a modern technology enterprise specializing in the research,development, production and sales of intelligent equipment for processing, cutting and wiring harnesses. The company's core products include: large square computer stripping machine, automatic terminal machine,corrugated pipe cutting machine, rotary pneumatic stripping machine, hexagonal crimping machine, and so on.

Fully automatic heat shrinkable sleeve terminal machine, automatic sheath terminal machine, automatic waterproof bolt terminal machine, automatic rubber shell terminal machine, automatic cable terminal machine, new energy automation equipment, etc. In addition, the company undertakes R&D and manufacturing of non-standard automation equipment.

Our Services & Strength

We are one of the most professional Chinese wire cable process machine manufacturers and leaders.

* 1year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to

pay for the delivery.

* OEM and customized service.

*

Best products and factory price.

*

On-time delivery and the shortest delivery time.

* 1year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to

pay for the delivery.

* OEM and customized service.

*

User manuals will go with relative machines.

QC: All products will be checked before delivery.

Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

Operation Guidance: If you have any problem with operation, please feel free to contact us.

Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

Operation Guidance: If you have any problem with operation, please feel free to contact us.

FAQ

1. Why choose us?

We provide overall solutions for processing equipment. Our standard equipment is very complete, all are in stock and can be shipped quickly. We have our own equipment factory, which can lightly customize equipment according to customer requirements, such as ordering different appearances and brands for agents, and non-standard equipment according to customer requirements.

2. Should I worry about the quality?

Before delivery, we do test the machine working condition for you.

Take a video of the normal operation of the machine to you, and then confirm the delivery

3.How can I know your machine is designed for my product?

You tell us the specific parameters of your product, or you can send us samples of your product and we test it on machine.

Video for you to make samples

4. How to operate the equipment?

My friend, don't worry about it, we have made vedio for you, it will show you how to do it step by step. Contact our engineers at any time when you don’t understand, support video and telephone communication

5.When the machine can't work well,What should I do?

The Engineer is online for 24-hours, they can check the problems and then give you solution way very soon. Please rest assured that manual will be offered along with machine,ensuring you can operate the machine easily.

We provide overall solutions for processing equipment. Our standard equipment is very complete, all are in stock and can be shipped quickly. We have our own equipment factory, which can lightly customize equipment according to customer requirements, such as ordering different appearances and brands for agents, and non-standard equipment according to customer requirements.

2. Should I worry about the quality?

Before delivery, we do test the machine working condition for you.

Take a video of the normal operation of the machine to you, and then confirm the delivery

3.How can I know your machine is designed for my product?

You tell us the specific parameters of your product, or you can send us samples of your product and we test it on machine.

Video for you to make samples

4. How to operate the equipment?

My friend, don't worry about it, we have made vedio for you, it will show you how to do it step by step. Contact our engineers at any time when you don’t understand, support video and telephone communication

5.When the machine can't work well,What should I do?

The Engineer is online for 24-hours, they can check the problems and then give you solution way very soon. Please rest assured that manual will be offered along with machine,ensuring you can operate the machine easily.

Hot Searches