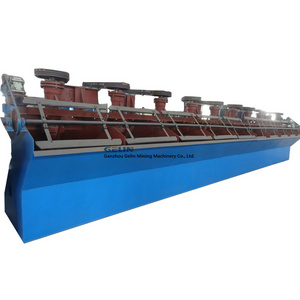

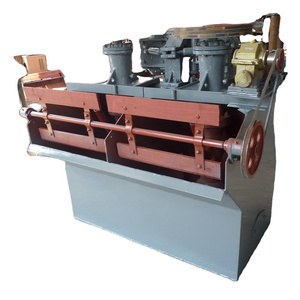

It is widely used in enrichment for non-ferrous metals, black metals and non-metals in medium and big flotation factories for the

roughing and scavenging concentration.

Structure Features:

1. Two sides backward blades of the impeller make the pulp bicirculating in the cell.

2. Large space between impeller and cover can have large air inhalation.

3. Low rotation speed of impeller extends the service life of the spare parts.

4. Forward tank and blind angel make the forth moving quickly.

1. Two sides backward blades of the impeller make the pulp bicirculating in the cell.

2. Large space between impeller and cover can have large air inhalation.

3. Low rotation speed of impeller extends the service life of the spare parts.

4. Forward tank and blind angel make the forth moving quickly.

Performance Features:

1. Large air inhalation and low energy consumption.

2. Long life of the spare parts.

3. Good for the coarse particles flotation.

1. Large air inhalation and low energy consumption.

2. Long life of the spare parts.

3. Good for the coarse particles flotation.