- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Xinli

-

Model Number:

-

Nano silicon carbide powder

-

Use:

-

coatings and paints

-

Usage:

-

coatings and paints

-

Mohs hardness:

-

9.5

-

Material:

-

SiC

-

99.9:

-

99.9 %

-

Crystal form (phase):

-

Alpha,Beta

-

Ca(ppm):

-

≤20

-

Al(ppm):

-

≤20

-

Fe(ppm):

-

≤20

-

Certification:

-

ISO9001

Quick Details

-

Type:

-

abrasive

-

Abrasive Grain Sizes:

-

50nm-500nm, 50nm-500nm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xinli

-

Model Number:

-

Nano silicon carbide powder

-

Use:

-

coatings and paints

-

Usage:

-

coatings and paints

-

Mohs hardness:

-

9.5

-

Material:

-

SiC

-

99.9:

-

99.9 %

-

Crystal form (phase):

-

Alpha,Beta

-

Ca(ppm):

-

≤20

-

Al(ppm):

-

≤20

-

Fe(ppm):

-

≤20

-

Certification:

-

ISO9001

|

|

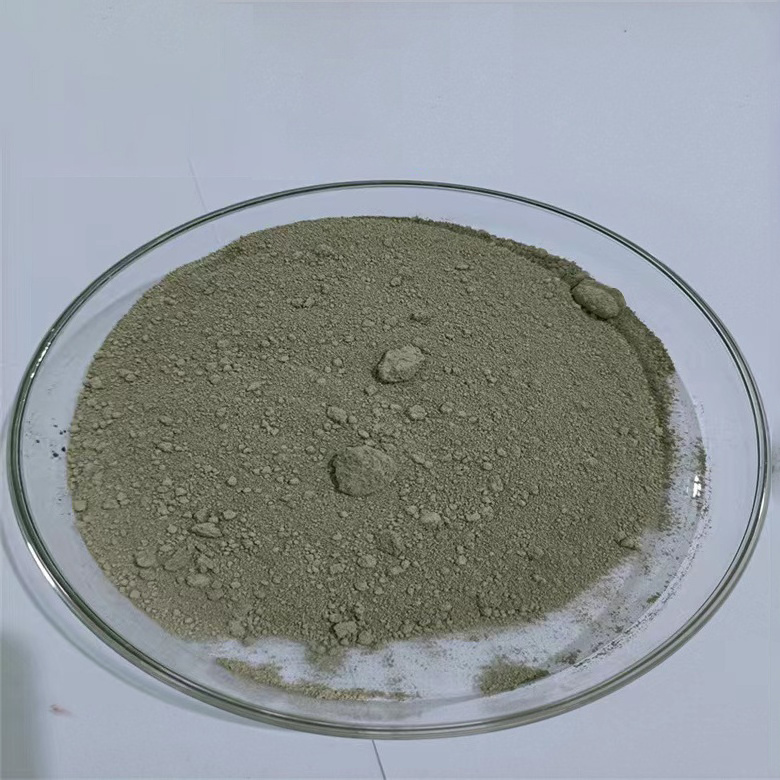

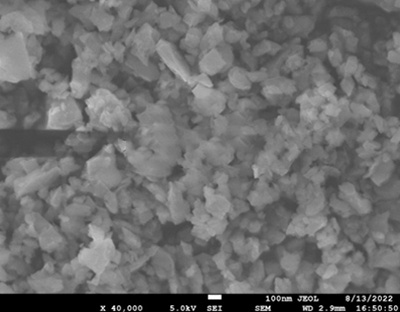

Nano-silicon carbide powder

CAS#: 409-21-2

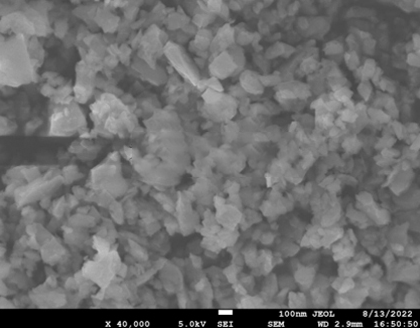

Nano-silicon carbide powder and ultra-fine silicon carbide powder are prepared by variable current laser ion beam gas phase method. Through variable current and high-voltage discharge, the shortcomings of DC arc (incomplete reaction, high product impurities, poor product stability, etc.) can be fully overcome. ).

Nano-silicon carbide powder Features:

Nano-silicon carbide powder and ultra-fine silicon carbide powder are prepared by variable current laser ion beam gas phase method. Through variable current and high-voltage discharge, the shortcomings of DC arc (incomplete reaction, high product impurities, poor product stability, etc.) can be fully overcome. ). It has high purity, small particle size distribution range, and high specific surface area; nano-silicon carbide has stable chemical properties, high thermal conductivity (165W/M.K), small thermal expansion coefficient, high hardness, Mohs hardness of 9.5, and microhardness of 2840~ 3320kg/mm2 is the first material wear-resistant additive, its hardness is between corundum and diamond, and its mechanical strength is higher than that of corundum; ultrafine silicon carbide powder has excellent thermal conductivity, and it is also a semiconductor, which can resist oxidation at high temperatures; Silicon carbide is wear-resistant, high temperature resistant, corrosion resistant, acid and alkali solvent resistant, applied to coatings and paints to increase wear resistance.

Technical indicators:

|

A verage particle size(nm) |

50nm |

100nm |

500nm |

50nm |

100nm |

500nm |

|

P urity(%)≥ |

99.9 |

99.9 |

99.9 |

99.9 |

99.9 |

99.9 |

|

Crystal form (phase) |

α |

α |

α |

β |

β |

β |

|

S pecific surface area m2/g |

40-60 |

30-40 |

5-10 |

40-60 |

30-40 |

5-10 |

|

Ca(ppm)≤ |

20 |

20 |

20 |

20 |

20 |

20 |

|

Al(ppm)≤ |

20 |

20 |

20 |

20 |

20 |

20 |

|

Fe(ppm)≤ |

20 |

20 |

20 |

20 |

20 |

20 |

|

Remarks: Purity, particle size, surface properties and other specifications can provide customized services according to user requirements |

||||||

Nano-silicon carbide powder a pplication

1. Nano-SiC powder modified high-strength nylon material: Nano-SiC powder has good compatibility and dispersion in polymer composite materials, and good combination with the matrix. The tensile strength of high-strength nylon alloy after modification is higher than ordinary PA6 is increased by more than 150%, and the wear resistance is increased by more than 3 times. It is mainly used for polymer parts of armored tracked vehicles, steering parts of automobiles, textile machinery, lining plates of mining machinery, train parts, etc., which can be sintered at a lower temperature to achieve densification;

2. The wear resistance of special engineering plastic polyetheretherketone (PEEK) modified by nanometer silicon carbide powder: the superfine silicon carbide powder after surface treatment of our company can greatly improve and increase the wear resistance of PEEK when the addition amount is about 5%. Wear resistance (improved by more than 30%);

3. The application of nano-silicon carbide powder in rubber tires: adding about 2% of ultra-fine silicon carbide powder can be modified without changing the original rubber formula, and its wear resistance can be improved without reducing its original performance and quality. It can be increased by 20%-40%. In addition, micron silicon carbide powder is used in rubber rubber rollers, printer fixing films and other rubber products such as wear-resistant, heat-dissipating, and temperature-resistant rubber products. Nano-silicon carbide is a good heat-conducting and wear-resistant filler;

4. Nano-SiC composite coating on the metal surface: Nano-scale particle binomial mixed particles are used, and nickel is used as the matrix metal to form a high-density electrodeposition composite coating on the metal surface with very good binding force. The metal surface has superhard (wear-resistant ) and anti-friction (self-lubricating) high temperature characteristics. The microhardness of the composite coating is greatly improved, the wear resistance is increased by 2-3 times, the service life is increased by 3-5 times, the bonding force between the coating and the substrate is increased by 40%, the covering ability is strong, the coating is uniform, smooth and meticulous;

5. Nano-silicon carbide powder and ultra-fine silicon carbide powder have other applications: high-performance structural ceramics (such as rocket nozzles, nuclear industry, etc.), wave-absorbing materials, anti-wear lubricants, high-performance brake pads, high-hardness wear-resistant powder coatings , composite ceramic reinforcement and toughening, etc.; structural coatings, functional coatings, protective coatings, absorbing materials, stealth materials, etc. in the aerospace industry; protective armor for tanks and armored vehicles; nano-silicon carbide powder can be used as ceramic knives and cutting tools , measuring tools, molds; structural ceramics, functional ceramics, and engineering ceramics that can be used for special purposes; igniters; electric heating elements for the electrical industry, and far-infrared generators.

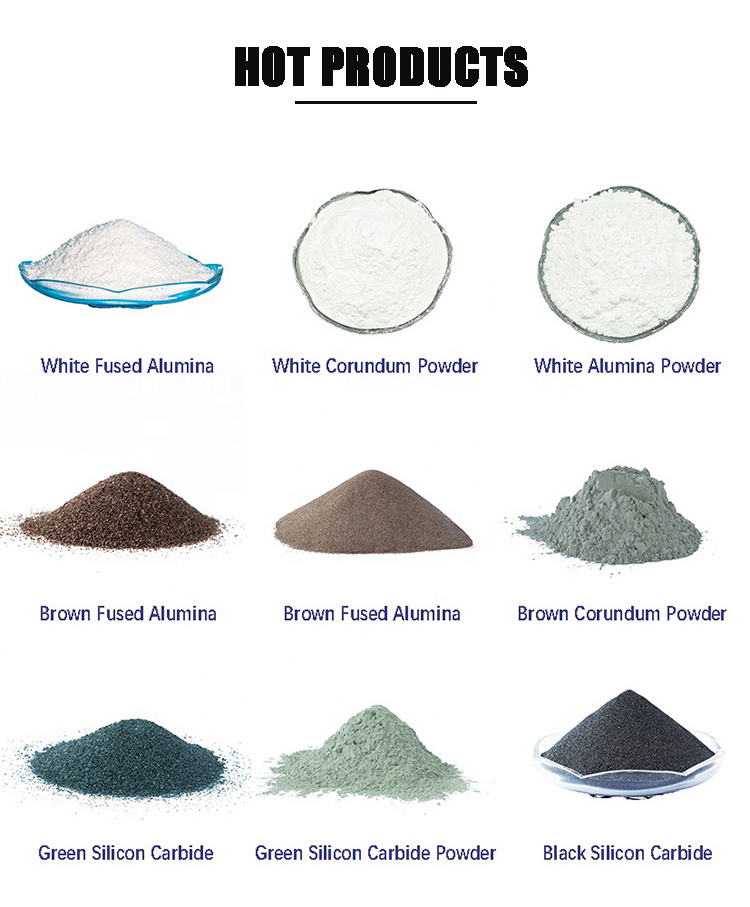

6. Black Silicon Carbide acking

1. 25kg woven bag, 40 woven bags/jumbo bag.

2. 25kg woven bag, 40 woven bags/pallet

3. 25kg paper bag, 40 paper bags/pallet

4. 25kg paper bag, 40 paper bags/paper box