The purpose of the flotation cell is to attach hydrophobic particles to air bubbles, so that they can float to the surface, form a froth, and can be removed.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Optional

-

Weight:

-

1800 KG

-

Product name:

-

SF type flotation machine

-

Application:

-

Powder separation and concentrate

-

Usage:

-

Widely use for 70 kinds metals

-

Advantage:

-

corrosion resistance long life

-

Recovery rate:

-

85-98%

-

Feeding density:

-

30-40%

-

Installation:

-

Under Technical Guidance

-

After sale service:

-

Life-long Service

-

Certification:

-

ISO9001 CE BV

-

Function:

-

for mineral rough, cleaning and reverse flotation

Quick Details

-

Production Capacity:

-

1-100tph

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XGN

-

Voltage:

-

Optional

-

Weight:

-

1800 KG

-

Product name:

-

SF type flotation machine

-

Application:

-

Powder separation and concentrate

-

Usage:

-

Widely use for 70 kinds metals

-

Advantage:

-

corrosion resistance long life

-

Recovery rate:

-

85-98%

-

Feeding density:

-

30-40%

-

Installation:

-

Under Technical Guidance

-

After sale service:

-

Life-long Service

-

Certification:

-

ISO9001 CE BV

-

Function:

-

for mineral rough, cleaning and reverse flotation

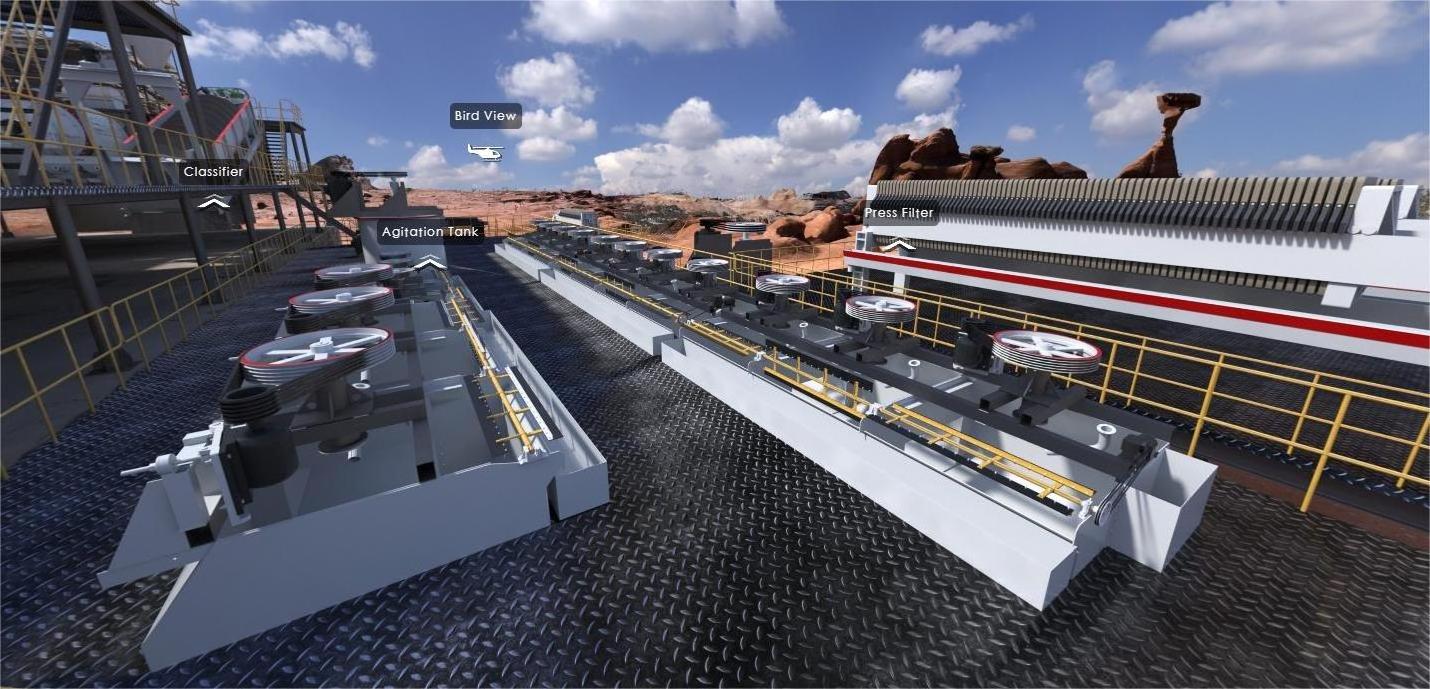

Products Description

Flotation Machine is suitable to separate non-ferrous metal, ferrous metal, noble metal, non-metallic mineral, chemical rough and etc. It can be used in roughing, scavenging, concentration or reverse flotation. In flotation machine, the slurry mixed with drugs would be stirred and inhaled air, so that valuable minerals adhere to bubbles, float to slurry surface and then scraped off ,other minerals still stay in the slurry, thus valuable minerals are separated out.it is the cost-effective one in the market self-priming slurry,self-breathing mining flotation equipment.

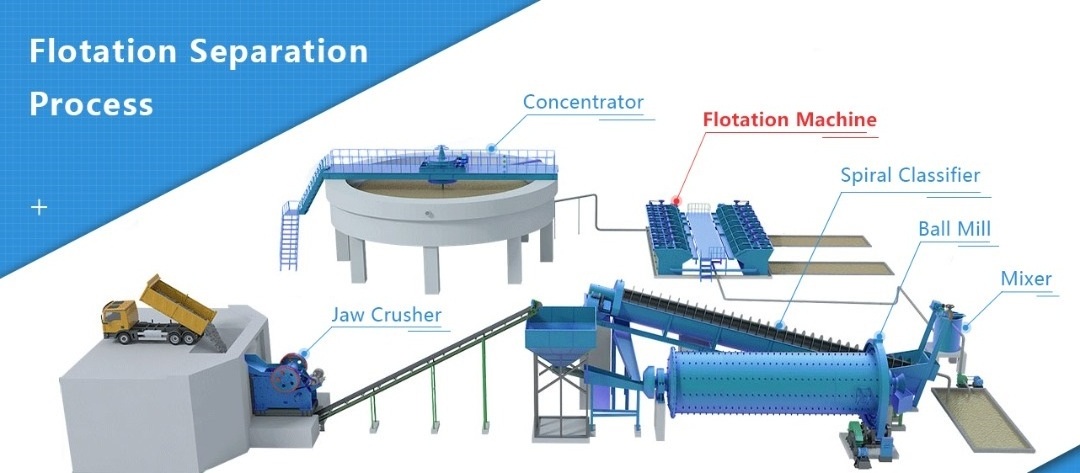

Flotation process introduction

Maintaining recovery and ensuring availability and sustainability while keeping costs under control is challenging. Our flotation solutions maximize your return on investment by enabling gains in throughput, grade and recovery, with minimized environmental impact.

Application range of the flotation machine:

*

Froth flotation has become one of the most important mineral processing methods. Almost all mineral resources can be floated by the Xingaonaifloatation machine.

* Ferrous metal ores: metals mainly concentrate iron and manganese, such as hematite, zincite, ilmenite, etc.

* Precious metal ores: metals mainly concentrate gold and silver.

* Non-ferrous metal ores: copper, lead, zinc, cobalt, nickel, molybdenum, antimony, etc.

* Sulfide minerals: galena, sphalerite, chalcopyrite, chalcocite, pyrite, molybdenite, nickel pyrite, etc.

* Oxide minerals: malachite, scheelite, heteropolar ore, cassiterite, wolframite, etc.

* Soluble saline minerals: potassium salt, rock salt, etc.

* Non-metallic saline minerals: fluorite, apatite, barite, etc.

* Non-metallic minerals and silicate minerals: coal, coal slurry, graphite, sulfur, diamond, quartz, mica, feldspar, beryl,

spodumene, clay minerals, etc.

* Ferrous metal ores: metals mainly concentrate iron and manganese, such as hematite, zincite, ilmenite, etc.

* Precious metal ores: metals mainly concentrate gold and silver.

* Non-ferrous metal ores: copper, lead, zinc, cobalt, nickel, molybdenum, antimony, etc.

* Sulfide minerals: galena, sphalerite, chalcopyrite, chalcocite, pyrite, molybdenite, nickel pyrite, etc.

* Oxide minerals: malachite, scheelite, heteropolar ore, cassiterite, wolframite, etc.

* Soluble saline minerals: potassium salt, rock salt, etc.

* Non-metallic saline minerals: fluorite, apatite, barite, etc.

* Non-metallic minerals and silicate minerals: coal, coal slurry, graphite, sulfur, diamond, quartz, mica, feldspar, beryl,

spodumene, clay minerals, etc.

Flotation Machine Performance

Xingaonai is a professional flotation machine manufacturer. It has strict quality requirements on the design of the equipment and a mature and excellent flotation machine production process. for different place and different project our flotation machine performace like show in the following table.

|

Country

|

Ore type

|

Grade of raw copper

|

Grade of copper concentration

|

Copper recovery rate(%)

|

|

Indonesia

|

Copper ore

|

1.77%

|

23.86%

|

95.24%

|

|

Bolivia

|

Tungsten ore

|

0.2%

|

21.20%

|

>65%

|

|

Peru

|

Copper-lead-zinc ore

|

85.2%

|

50.4%

|

87.3%

|

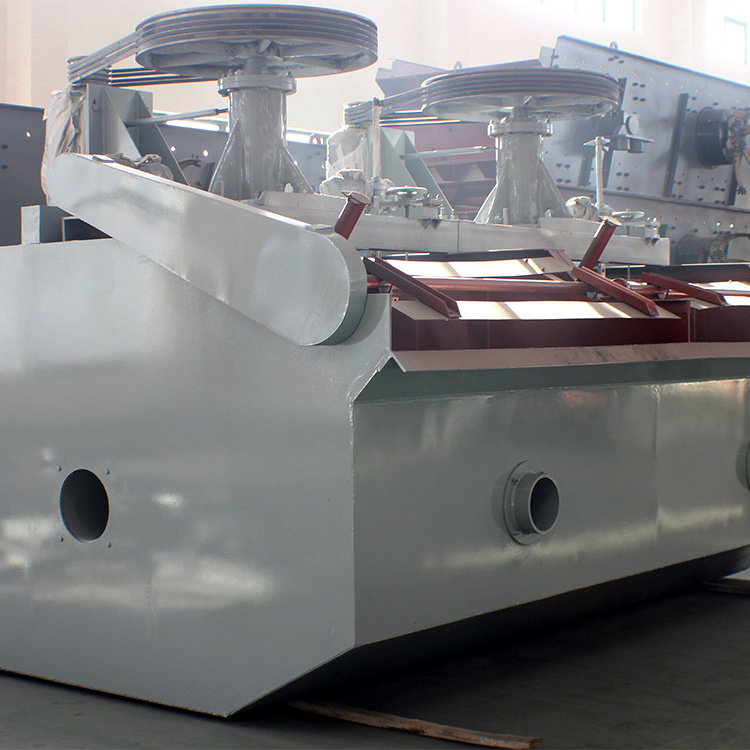

Machine Structure

Working Principle

the rotation of the impeller produces centrifugal action to form a negative pressure. On the one hand, sufficient air is inhaled to mix with the ore pulp, on the other hand, the ore pulp is stirred to mix with drugs, and the interaction between mineral particles and air bubbles is used to achieve the purpose of mineral separation.

Flotation cell

It has a slurry inlet and a gate device for adjusting the slurry surface. It is mainly composed of a tank welded with steel plate and a gate welded with steel plate and round steel.

Mixing device

Being mainly composed of the pulley, impeller, vertical shaft and so on, it is used to mix ore pulp to prevent ore sand from settling in the cells.

Aeration device

It consists of the intake-tube. When the impeller rotates, a negative pressure is generated in the impeller cavity, so the air is inhaled through the hollow pump tube and dispersed in the slurry to form a bubble cluster.

Mineralized foam discharging device

The device, which is mainly composed of the motor, reducer and scraper, scrapes out the foam floating

on the surface of

on the surface of

Product Parameters

|

Specification model

|

CTBC1018

|

CTBC1024

|

CTBC1030

|

CTBC1218

|

CTBC1224

|

CTBC1230

|

|

Cylinder diameter(mm)

|

1000

|

1000

|

1000

|

1200

|

1200

|

1200

|

|

Cylinder length(mm)

|

1800

|

2400

|

3000

|

1800

|

2400

|

3000

|

|

Cylinder field strength(mt)

|

300~500

|

300~500

|

300~500

|

300~500

|

300~500

|

300~500

|

|

Cylinder rotating speed(r/min)

|

23

|

23

|

23

|

20

|

20

|

20

|

|

Dry ore processing capacity(t/h)

|

36~54

|

44~75

|

66~103

|

47~82

|

62~105

|

83~129

|

|

Feed particle size(mm)

|

0~4

|

0~4

|

0~4

|

0~4

|

0~4

|

0~4

|

|

Pulp concentration(%)

|

20~50

|

20~50

|

20~50

|

20~50

|

20~50

|

20~50

|

|

Motor power(kw)

|

5.5

|

7.5

|

7.5

|

7.5

|

11

|

11

|

|

Gross weight(mm)

|

5.2

|

6.4

|

7.1

|

6.7

|

7.2

|

8.9

|

|

Equipment length(mm)

|

3160

|

3790

|

4460

|

3380

|

4190

|

4770

|

|

Equipment width(mm)

|

2250

|

2250

|

2250

|

2460

|

2460

|

2460

|

|

Equipment height(mm)

|

1750

|

1750

|

1750

|

2000

|

2000

|

2000

|

Why Choose Us

Stone Crushing & Grinding First Brand

We have

3

manufacturing base

Zhengzhou City, Henan Province

Wuzhi City, Henan Province

Xiuwu City, Henan Province

We have

2

brand

Zhengzhou Xingaonai Heavy Industry Machinery Co., Ltd.

(For middle hard stone solutions)

Jiaozuo Pathfinder Heavy Industry

Machinery Co.,Ltd,

(For hard stone solutions)

We have 33 service station worldwide

Give clear solutions within 12 hours

Rush to the site within 24 hours

Xingaonai Group is specialized in R&D and manufacturing of stone crushing, sand making, powder grinding, screening, feeding, conveying, dust collecting and other equipment, we give One-stop Green-Smart-Efficient mining solutions.

Innovation can't just be said in words, it must be turned into a project, and the innovation must be implemented. Today, the company has continuously developed crushing equipment, sand making equipment, mineral processing equipment, supporting equipment, etc. with keen market insight and forward-looking Multi-series, more than 100 models of highly influential products have created more value for enterprises and society.

Our group continuously researches and develops new equipment, adjusts product structure, improves product system, intensively cultivates the core fields of "building crushing, mine crushing, industrial sand making, green building materials, and metal beneficiation", builds three modern equipment production bases, and establishes large-scale equipment The production line continuously improves the production capacity and market influence of the enterprise. In addition to the XGN-Q series hammer crusher, the types of medium and large intelligent crushing equipment are also becoming more and more perfect.

Exhibition

Packaging & Logistics

Packing

1.The equipment and wearing parts are packed in plastic film and wooden box.

2.FCL:Shipped in standard export container.

3.Various packaging methods can be provided according to customer requirements, such as: fumigation-free wooden boxes, steel boxes, etc.

Sea freight

We ship the goods to China's main seaports, such as Qingdao, Tianjin, Shanghai, etc., and then ship the equipment to your country by sea.

FAQ

A) What is the core competitiveness of the company?

We regard product development as a key task, and develop new products with strong technology, intensive knowledge and good market prospects by tracking demand hot spots and aiming at technological progress in the industry.

B) Product line coverage?

The main business is the equipment required for the production line with an output of 100-6000 tons per hour.

C) What is the main business direction of the product?

Our comprehensive solutions for a range of processes in rock crushing and metal ore.

D) Does the company undertake to build a complete production line?

According to customer needs, we tailor-made recommendations or customization, fast and accurate understanding, special car transportation and distribution, customer inspection and after-sales service, escorting you.

E) Does the company have relevant crusher parts services?

We can provide all kinds of accessories for crushing and screening equipment, with advanced technology, reliable performance and durability, to ensure that customers' needs can be met in a timely and effective manner.

Hot Searches