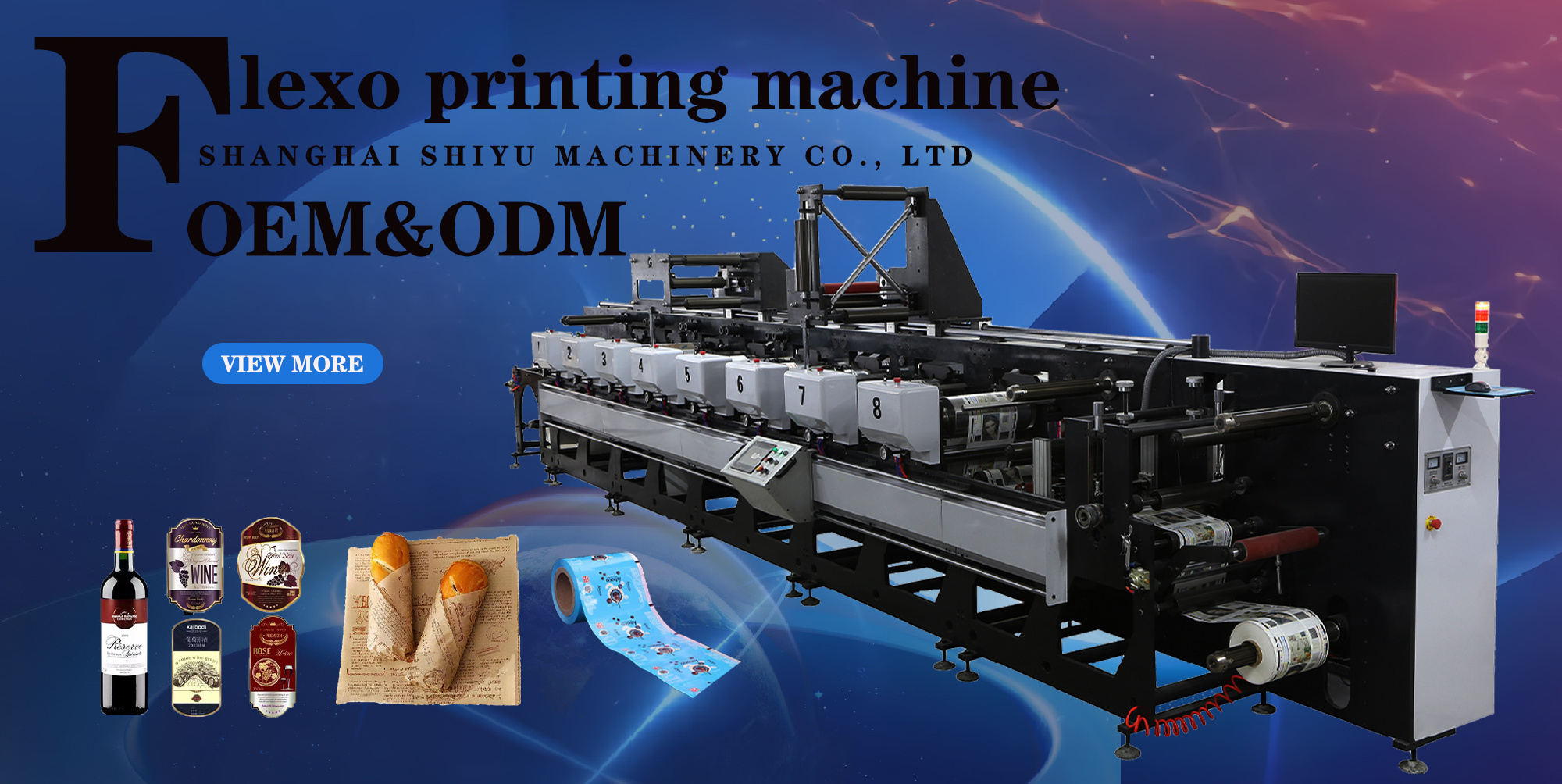

- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

2100*1300*2500(mm)

-

Weight:

-

2200 KG

-

Rewinding Diameter:

-

650mm

-

Unwinding Diamete:

-

650mm

-

Printing Width:

-

310mm

-

Web Width:

-

320mm

-

Options:

-

Laminationi

-

Printing Page:

-

Single Faced

-

Printing Color:

-

1-5 Color

-

Anilox Roller:

-

Ceramic Anilox Roller

-

Dryer:

-

UV& IR

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SY

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

2100*1300*2500(mm)

-

Weight:

-

2200 KG

-

Rewinding Diameter:

-

650mm

-

Unwinding Diamete:

-

650mm

-

Printing Width:

-

310mm

-

Web Width:

-

320mm

-

Options:

-

Laminationi

-

Printing Page:

-

Single Faced

-

Printing Color:

-

1-5 Color

-

Anilox Roller:

-

Ceramic Anilox Roller

-

Dryer:

-

UV& IR

This machine features:

1. Adopt the ceramic anilox cylinder to transfer the ink.

2. Each printing unit adopts 3600 plate-adjustment.

3. Three die-cutting stations, the first and second die-cutting station can do double sides working, the third die-cutting station can be used as sheeter.

4. Computerized web-guiding system is installed in the front of printing unit, it ensures the material always in the right

position. (standard configuration)

5. After sheeting in the third die-cutting station, conveyor belt can output the products orderly. (option)

6. Unwinding and rewinding tension are auto-controlled by magnetic powder, two Rewinders is possible in this machine.

7. Video inspecting system is an option, it can watch the printing quality when in high speed.

8. The ink rollers will be separated from the printing roller, and keep running when the machine stops.

9. Main machine inverter is imported.

10. The machine can finish material-feeding, printing, varnishing, drying, laminating, die-cutting, rewinding and sheeter in a

lump. It is an ideal machine for printing note and top-grade adhesive label.

Optional:

1, three groups of die-cutting station

2, UV dryer system

3, conveyor device off

4, put, are the magnetic winding automatic tension control

5, correcting device and reverse device

6. Unwinding and rewinding are controlled by magnetism power brake, clutch. (or by automatic tension controller of mitsubishi,made in Japan).

7. Printing unit adopt 360 for registration.

8. Printing unit have one infrared to dry the device group each.

9. The rubber roller can break away from automatically while parking, and running at a low speed, in order to avoid water being black to be dry.

10. The main motor is adopted the import stepless regulation of frequency conversion.

11. Unwinding, printing, varnishing, IR drying, laminating and rewinding can be finished in one process, this kind of printing

machine is best for each printing companies to print on adhesive-paper labels and other commercial label.

1. Adopt the ceramic anilox cylinder to transfer the ink.

2. Each printing unit adopts 3600 plate-adjustment.

3. Three die-cutting stations, the first and second die-cutting station can do double sides working, the third die-cutting station can be used as sheeter.

4. Computerized web-guiding system is installed in the front of printing unit, it ensures the material always in the right

position. (standard configuration)

5. After sheeting in the third die-cutting station, conveyor belt can output the products orderly. (option)

6. Unwinding and rewinding tension are auto-controlled by magnetic powder, two Rewinders is possible in this machine.

7. Video inspecting system is an option, it can watch the printing quality when in high speed.

8. The ink rollers will be separated from the printing roller, and keep running when the machine stops.

9. Main machine inverter is imported.

10. The machine can finish material-feeding, printing, varnishing, drying, laminating, die-cutting, rewinding and sheeter in a

lump. It is an ideal machine for printing note and top-grade adhesive label.

Optional:

1, three groups of die-cutting station

2, UV dryer system

3, conveyor device off

4, put, are the magnetic winding automatic tension control

5, correcting device and reverse device

6. Unwinding and rewinding are controlled by magnetism power brake, clutch. (or by automatic tension controller of mitsubishi,made in Japan).

7. Printing unit adopt 360 for registration.

8. Printing unit have one infrared to dry the device group each.

9. The rubber roller can break away from automatically while parking, and running at a low speed, in order to avoid water being black to be dry.

10. The main motor is adopted the import stepless regulation of frequency conversion.

11. Unwinding, printing, varnishing, IR drying, laminating and rewinding can be finished in one process, this kind of printing

machine is best for each printing companies to print on adhesive-paper labels and other commercial label.

|

Max.printing speed

|

55m/min

|

|

Printing color

|

5colors

|

|

Max paper roll width

|

320mm

|

|

Max printing width

|

310mm

|

|

Max unwinding diameter

|

650mm

|

|

Max rewinding diameter

|

650mm

|

|

Printing girth

|

175-580mm

|

|

Chromatography precision:

|

±0.1mm

|

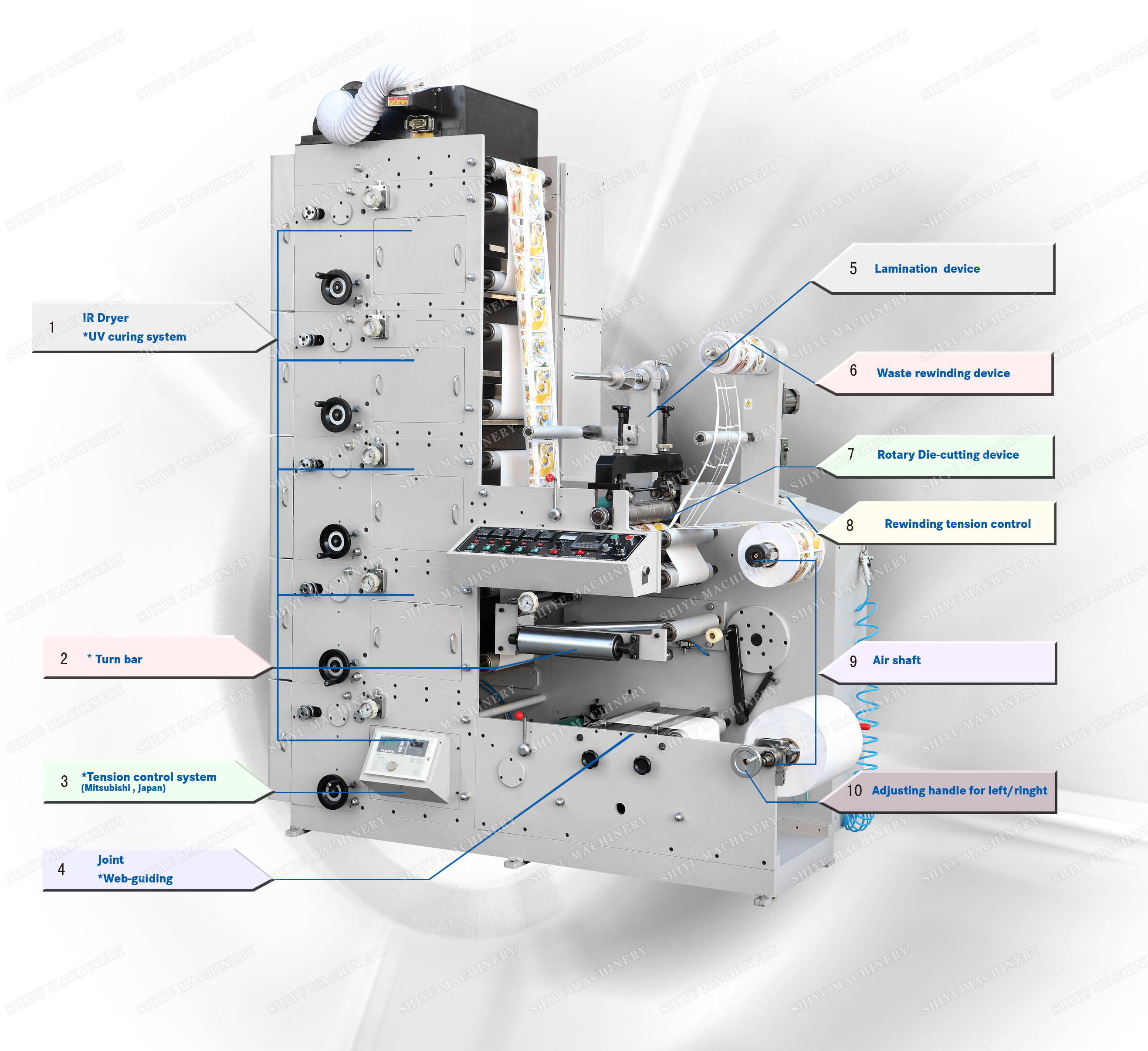

control panel

Power Supply, Stop Button, Start Button and Emergency Stop.Temperature Controller for each Heating Oven.and bottom roller tension control

Die Cutting Unit

Rotary die cutting. Magnetic cylinder need to be customized according to your label size Flexible dies can be customized according to your demand

Printing Unit

Printing station comes with ink rubber roller, ceramic anilox cylinder, printing plate cylinder, scrapper blade and ink

container.helical gear

container.helical gear

UV dryer system

The supporting equipment of the printing equipment can provide the efficiency and effect of the finished printing products.

Web Guide System

Control paper move straightly.

Auto Constant Tension Controller

Auto Constant Tension Controller For Unwind and Rewind

Hot Searches