- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Injection Mold

-

Product Name:

-

plastic automotive parts mould

-

Material:

-

Polyurethane PU/PP/PC/ABS

-

Mould life:

-

250000-300000shots

-

Design Software:

-

UG,PROE,CAD,CATIA,SOLIDWORKS

-

Mould running:

-

Full automaticity

-

Cavity:

-

Single, Multi-Cavity

-

Size:

-

all kinds

-

Runner:

-

hot/cold

-

Molding time:

-

30-40s

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

yongjia

-

Model Number:

-

Injection Mold

-

Product Name:

-

plastic automotive parts mould

-

Material:

-

Polyurethane PU/PP/PC/ABS

-

Mould life:

-

250000-300000shots

-

Design Software:

-

UG,PROE,CAD,CATIA,SOLIDWORKS

-

Mould running:

-

Full automaticity

-

Cavity:

-

Single, Multi-Cavity

-

Size:

-

all kinds

-

Runner:

-

hot/cold

-

Molding time:

-

30-40s

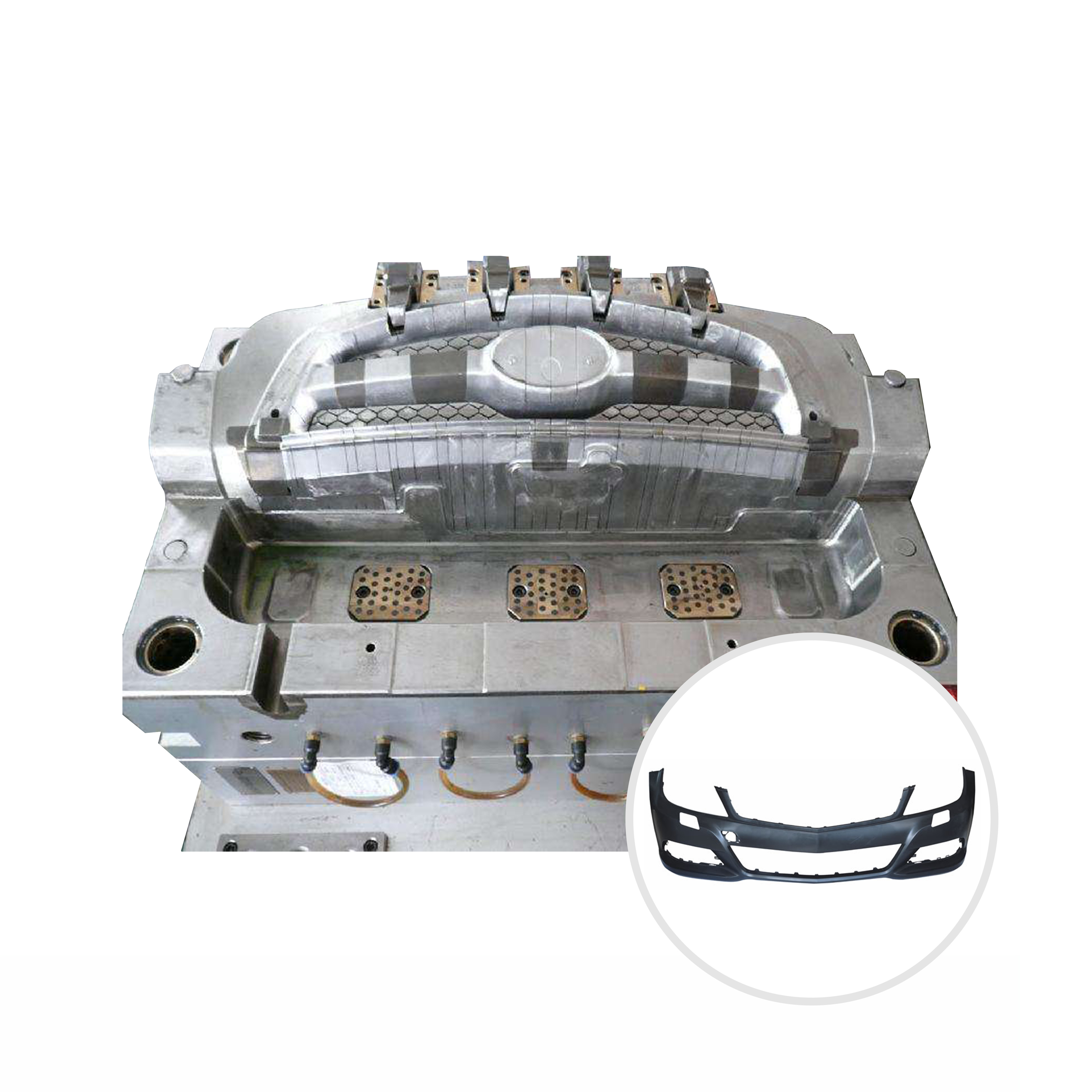

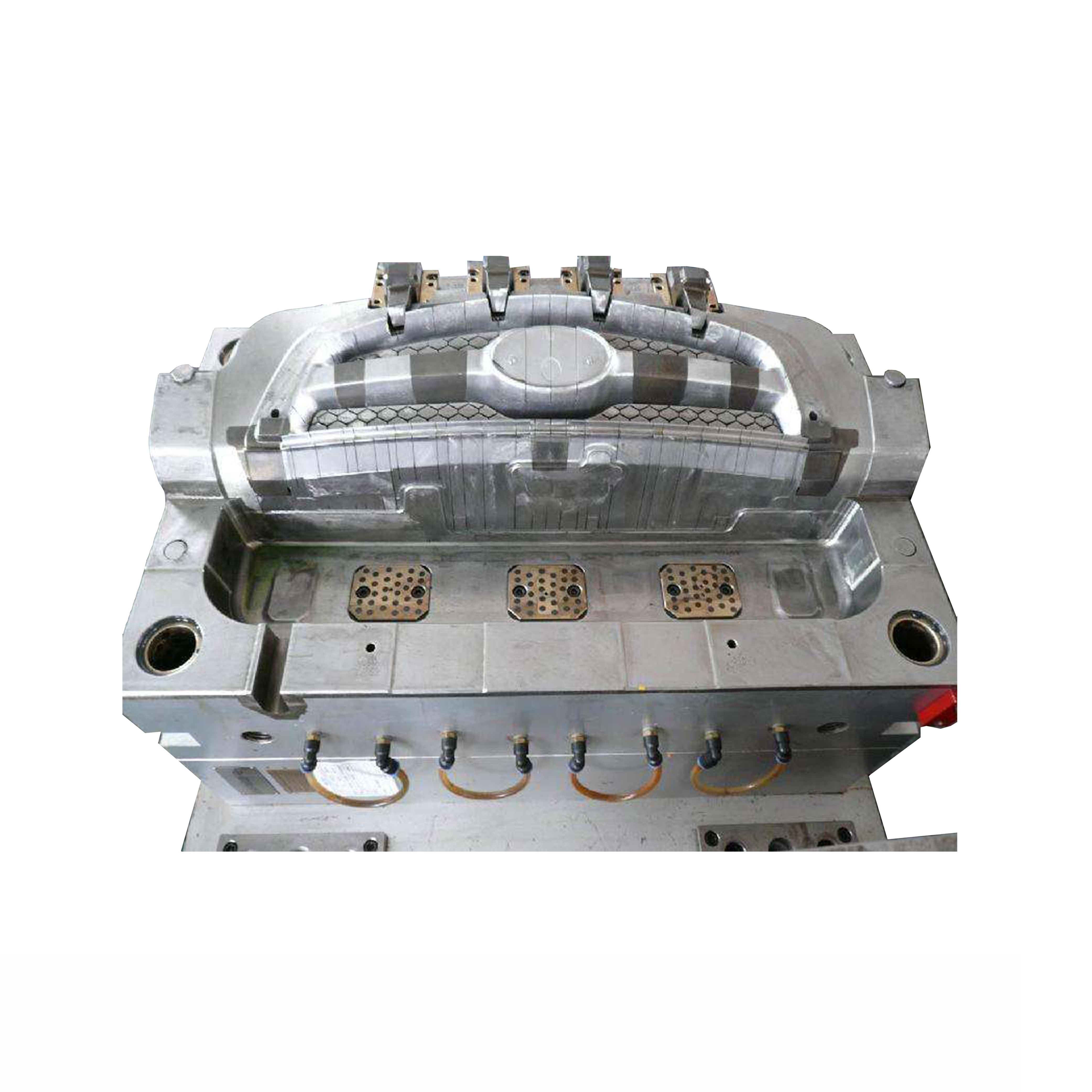

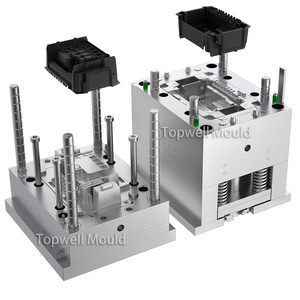

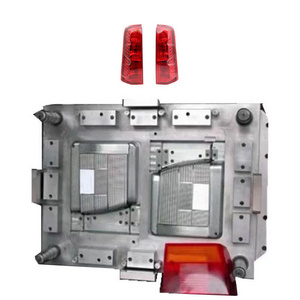

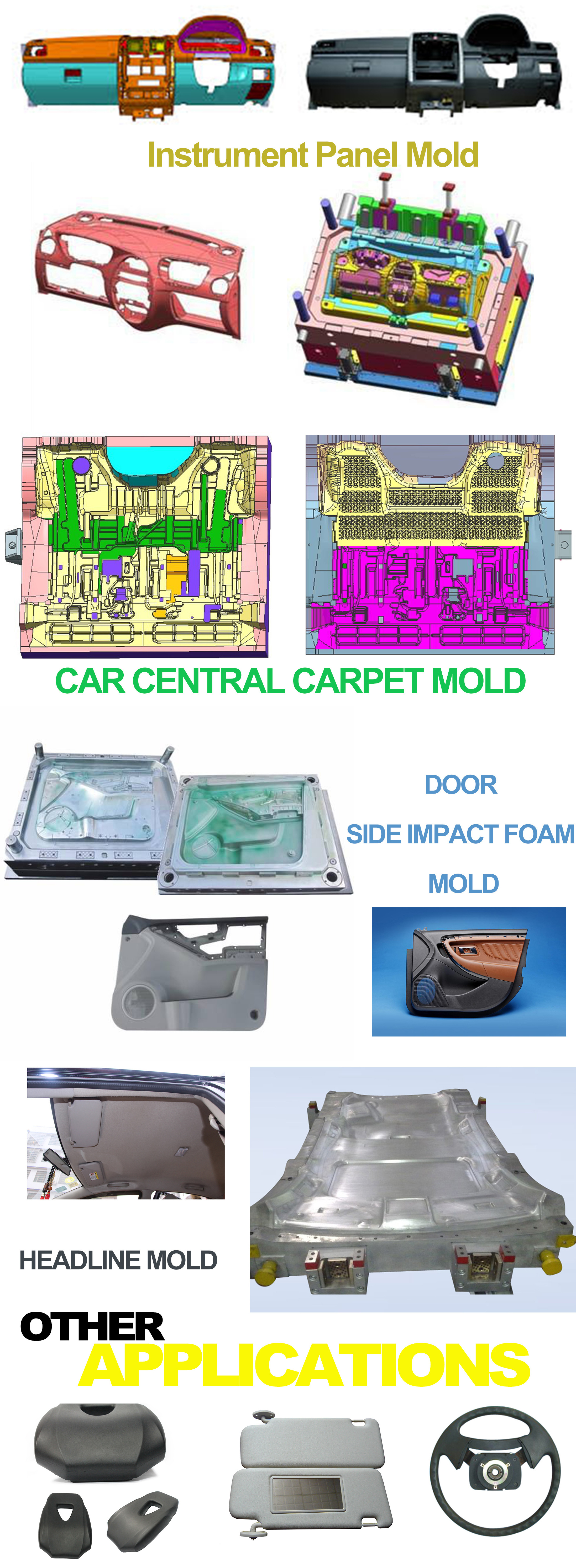

Automotive interior parts Injection Mold Mould

2.one-stop solution

3.mould life,1 million shots

Our Automotive interior parts Injection Mold Mould advantange:

2)Over 16 years in precision plastic mould manufacturing,collected rich experience

3)Stable technical team and frequent training system,middle management peopble are all working for over 10 year in our shop

4)Advanced maching equipment,CNC center from Sweden,Mirror EDM and JAPAN precision WIRECUT

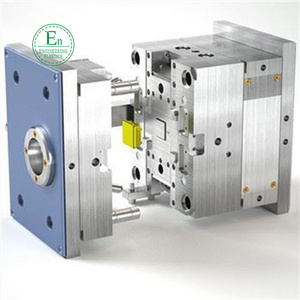

Our professional one-stop plastic mould custom service:

2)Plastic injection mold making,two shot injection mold,gas assisted mold

3)Precision plastic molding:two shot molding,precision plastic molding and gas assisted molding

4) Plastic Secondary operation,like Silk-screeking,UV,PU painting,Hot stamping,Laser engraving,Ultrasonic welding,Plating etc.

|

Mold Type

|

Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc

|

|

Main services

|

Prototypes, Mold design, Mold making, Mold tesing,

low volume/high volume plastic production |

|

Steel material

|

718H,P20,NAK80,S316H,SKD61, etc.

|

|

Plastic production Raw material

|

PP,PU,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc

|

|

Mold base

|

HASCO ,DME ,LKM,JLS standard

|

|

Mold runner

|

Cold runner, hot runner

|

|

Mold hot runner

|

DME, HASCO, YUDO,etc

|

|

Mold cold runner

|

point way, side way, follow way, direct gate way,etc.

|

|

Mold strandard parts

|

DME, HASCO, etc.

|

|

Mold life

|

>300,000 shots

|

|

Mold hot treatment

|

quencher, nitridation, tempering,etc.

|

|

Mold cooling system

|

water cooling or Beryllium bronze cooling, etc.

|

|

Mold surface

|

EDM, texture, high gloss polishing

|

|

Hardness of the steel

|

20~60 HRC

|

|

Equipments

|

High speed CNC, standard CNC, EDM, Wire cutting, Grinder,Lathe, Milling machine, plastic injection machine

|

|

Month Production

|

100 sets/month

|

|

Mold Packing

|

standard exporting Wooden case

|

|

Design software

|

UG, ProE, Auto CAD, Solidworks, etc.

|

|

Certificate

|

ISO 9001:2008

|

|

Lead time

|

25~30 days

|

Yongjia Polyurethane Co., Ltd.

is a professional machinery manufacturer in PU industry combined with design, development, production. Founded in 2013, the construction area of over 10,000 square meters, is the China forefront polyurethane technology company. At present our company's products range covers:high pressure pouring machine, low pressure foaming machine, PU spraying foam machine, PU elastomer casting machine, also we customize to make production line according to clients requirement,like in flexible foam system we make the lines: PU shoe /sole/insole production line(Egypt),anti-fatigue mat production line(India),memory pillow production line,Albania,elastic ball production line(Mexico),car seat and cushion production line(Morocco),PU slow rebound ear plugs line(India);rigid foam system we make the line:PU decorative molding crown cornice line(Saudi Arab), float trowel making line(Saudi Arab, Pakistan), cold storage panel production line(Uzbekistan),sandwich panel production line(Iraq).Elastomer line:forklift wheel casting line;coal sieve screen select line(Russia).

Our Team

We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines.

Our Service

1. Professional and patient consulting service to help you find the suitable solution.

2.Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3.Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4.Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5.Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6.For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7.For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8.We give an accessory box for free.

9.We offer development solutions for raw material formulations.

10.If you need to visit the factory, we will arrange for personnel to pick up the airport.

Visitors and Exhibitions

We participated in many exhibitions of polyurethane raw materials, polyurethane foam products and polyurethane PU foam machines. Our products left a very good impression to everyone at the show, some customers even placed orders on the spot.

Certificate

We are professional factory in PU industry with more than 10 years experience, covering high pressure pouring machine,low pressure foaming machine, PU spraying foam machine,PU elastomer casting machine and production line.

2.Where is your factory ?

Our Factory is located in Wuxi city, Jiangsu Province.

3.How can I get your factory?

By air: You can take a plan to WUXI airport from China, if you fly from Korea ,Japan, USA, Singapore, Taiwan, Thailand you will can directly fly to us.

By Train: You can stop at WUXI station, Not WUXI EAST station.

4.Do you provide pick-up service?

Yes, of course. If you are in Wuxi airport or station, we can arrange a special car to pick you up directly to our factory.

5.What transport methods do you have for your PU mold?

For PU mold, sea and air transportation are both available.

6.How can I buy your PU mold and pay for the money?

First, you can place an order in Alibaba via L/C, T/T, D/P and other payment methods accepted by Alibaba. Or you can pay US dollars by bank transfer, another way you can pay RMB and transfer to our RMB account.

Good Feedback from our Australian client who buy a low pressure PU polyurethane foaming machine.

Real comment for our PU polyurethane flexible foam shoe sole and insole making production line.