- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3.5KW

-

Dimension(L*W*H):

-

1900x1500x1150MM

-

Weight:

-

760 KG

-

Product name:

-

Leather Splitter Machine

-

Application:

-

Leather Splitting Machine

-

Function:

-

Leather Splitting Machine

-

Keywords:

-

Band Knife Leather Splitting Machine

-

Certification:

-

CE

-

Name:

-

Leather Belt Slitting Machine

-

Suitable for:

-

Leather Goods Industry

-

Working width:

-

400mm

Quick Details

-

Voltage:

-

AC380V/220V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DAFENG

-

Power:

-

3.5KW

-

Dimension(L*W*H):

-

1900x1500x1150MM

-

Weight:

-

760 KG

-

Product name:

-

Leather Splitter Machine

-

Application:

-

Leather Splitting Machine

-

Function:

-

Leather Splitting Machine

-

Keywords:

-

Band Knife Leather Splitting Machine

-

Certification:

-

CE

-

Name:

-

Leather Belt Slitting Machine

-

Suitable for:

-

Leather Goods Industry

-

Working width:

-

400mm

Product Description

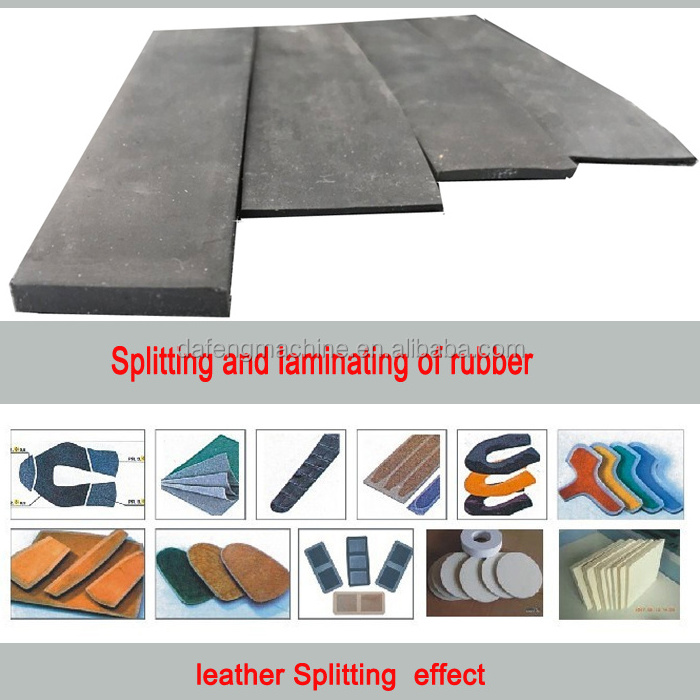

Leather Production Machine 400 PLC China Band Knife Leather Splitting Machine

The machine adapts to splitting the hard or soft leather symmetrically, which the width is less than 520mm and the thickness is less than 8mm, according the required thickness in the industry of leather products, improve the quality of products and strengthen the competitiveness of markets.

CHARACTERS

1.DF-L520W inherits the DF-L620W great function and all advantages.

2.With automatic feed registration device, no need to adjust cutting tool.

3.With function of dropping out when it is splitting.

4.Automatic pause system when leather material entangles in and automatic detection system of electronic phase.

5.Freestanding set of dust absorbing and knife grinding dust absorbing device.

6.The outsize flying wheel makes the operation of band knife more steady and exact.

CHARACTERS

1.DF-L520W inherits the DF-L620W great function and all advantages.

2.With automatic feed registration device, no need to adjust cutting tool.

3.With function of dropping out when it is splitting.

4.Automatic pause system when leather material entangles in and automatic detection system of electronic phase.

5.Freestanding set of dust absorbing and knife grinding dust absorbing device.

6.The outsize flying wheel makes the operation of band knife more steady and exact.

|

Model

|

DF-L520W

|

|

Max width of split

|

520MM

|

|

Min thickness of split

|

0.15mm with top bar、

|

|

|

0.5mm with top feed roller

|

|

Max thickness of split

|

8MM

|

|

Feeding speed

|

1-20M/Min

|

|

Specification of band knife

|

3810x50x0.8MM

|

|

Power of motor

|

3.5KW

|

|

Package size

|

1900x1500x1150MM

|

|

Net weight

|

760KG

|

|

Gross weight

|

850KG

|

Specification

|

item

|

value

|

|

Applicable Industries

|

Manufacturing Plant

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts

|

|

Local Service Location

|

Indonesia, Thailand

|

|

Showroom Location

|

None

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Motor

|

|

Condition

|

New

|

|

Automatic Grade

|

Semi-automatic

|

|

Place of Origin

|

China

|

|

|

Guangdong

|

|

Brand Name

|

DAFENG

|

|

Type

|

SPLITTING MACHINE

|

|

Voltage

|

AC380V/220V/50Hz

|

|

Power

|

3.2KW

|

|

Dimension(L*W*H)

|

1500*1250*1270mm

|

|

Weight

|

650KG

|

|

Certification

|

CE

|

|

Warranty

|

1 Year

|

|

After-sales Service Provided

|

Free spare parts, Field maintenance and repair service, Online support, Video technical support

|

|

Product name

|

Leather Splitter Machine

|

|

Application

|

Leather Splitting Machine

|

|

Function

|

Leather Splitting Machine

|

|

Keywords

|

Band Knife Leather Splitting Machine

|

shoe machine application

shoe manufacturing process

Why Choose Us

Hot Searches