- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V/Customized

-

Power:

-

45KW/55kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

15000*800*1600mm

-

Year:

-

2020

-

Material:

-

304 Stainless Steel

-

Capacity:

-

150kg/h

-

Application:

-

Puffed food/ snack

-

Energy:

-

Electricity Gas

-

Name:

-

Extruded pellet corn chip snack making machine

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Eagle

-

Voltage:

-

380V/220V/Customized

-

Power:

-

45KW/55kw

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

15000*800*1600mm

-

Year:

-

2020

-

Material:

-

304 Stainless Steel

-

Capacity:

-

150kg/h

-

Application:

-

Puffed food/ snack

-

Energy:

-

Electricity Gas

-

Name:

-

Extruded pellet corn chip snack making machine

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE

Product Description

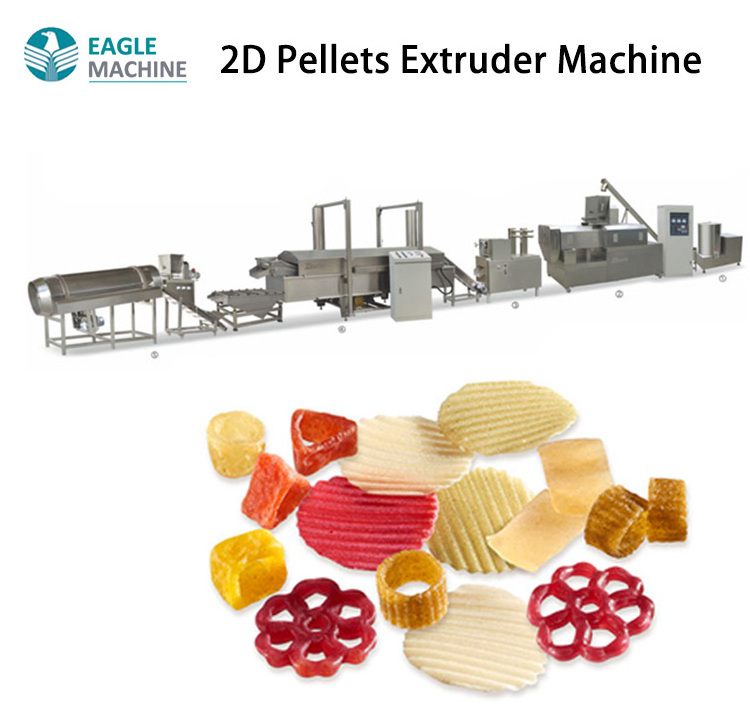

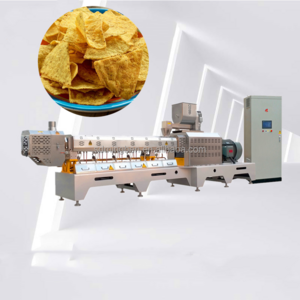

Introduction:

The 2D/3D Pellet/Fryum Process Line with our segment screw technology to ensure the precise control during production, you can have a multiple choice to use different materials to make higher quality, multiple types pellet This line can use wheat flour,corn starch, potato starch, whole potato flour as raw material. Through screw extruding, it shapes various types shape, through drying, frying and flavoring, it makes puffed leisure snacks with crispy, tasty mouthfeel, smooth surface, and different vivid shapes.

Production Process Line:

Flour Mixer → Automatic Feeder→ Double Screw Extruder( With Cooling Tower, Water Injector) → Pattern Machine→ Compounding Machine→Lifter→ Recycling Dryer → Continous Fryer→ De-oiler→ Flavoring Line

Basic Formula:

Basic Formula: wheat flour, corn starch, potato starch, whole potato flour

The 2D/3D Pellet/Fryum Process Line with our segment screw technology to ensure the precise control during production, you can have a multiple choice to use different materials to make higher quality, multiple types pellet This line can use wheat flour,corn starch, potato starch, whole potato flour as raw material. Through screw extruding, it shapes various types shape, through drying, frying and flavoring, it makes puffed leisure snacks with crispy, tasty mouthfeel, smooth surface, and different vivid shapes.

Production Process Line:

Flour Mixer → Automatic Feeder→ Double Screw Extruder( With Cooling Tower, Water Injector) → Pattern Machine→ Compounding Machine→Lifter→ Recycling Dryer → Continous Fryer→ De-oiler→ Flavoring Line

Basic Formula:

Basic Formula: wheat flour, corn starch, potato starch, whole potato flour

Specification

|

Model

|

Installed Power(kw)

|

Capacity (kg/h)

|

Size

|

|

DP65 processing line

|

18/22KW

|

120-150kg/h

|

2.6x0.9x1.7m

|

|

DP70 processing line

|

30/45KW

|

200-250kg/h

|

2.8x0.9x1.7m

|

|

DP85 processing line

|

75kw/90kw

|

400-600kg/h

|

3.4x1.0x1.9m

|

Hot Searches