- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SANLE

-

Model Number:

-

eps sandwich panel

-

Product name:

-

Precast concrete wall eps sandwich panel price

-

Usage:

-

Interior Wall Partition

-

Material:

-

Calcium Silicate Board+EPS+cement

-

Advantage:

-

Eco-friendly

-

Thickness:

-

50/75/100/125/150mm/200mm

-

Certificate:

-

CE

-

Thermal conductivity:

-

0.19 W(m.k)

-

Hanging force:

-

≥1000N

-

Dry shrinkage rate:

-

<0.5 Mm/m

-

Combustion performance:

-

grade A

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SANLE

-

Model Number:

-

eps sandwich panel

-

Product name:

-

Precast concrete wall eps sandwich panel price

-

Usage:

-

Interior Wall Partition

-

Material:

-

Calcium Silicate Board+EPS+cement

-

Advantage:

-

Eco-friendly

-

Thickness:

-

50/75/100/125/150mm/200mm

-

Certificate:

-

CE

-

Thermal conductivity:

-

0.19 W(m.k)

-

Hanging force:

-

≥1000N

-

Dry shrinkage rate:

-

<0.5 Mm/m

-

Combustion performance:

-

grade A

Precast concrete wall eps sandwich panel price

Artificial House, And Also Made Man.

Are you still working in dirty and wet construction site, moving many heavy machines to the site? Are you still waiting for more than half a year before you can move inside to your new house? Are you still paying high salary to the workers and still unhappy about the final work? Are you still...?

You are so lucky to be here and get to know the best substitute to traditional concrete wall, it is called eps cement sandwich panel. Comparison with other wall materials, this one is more stronger and longer life span with many advantages and wide usages.

Firstly, let me tell you the what exactly is it and its structure.

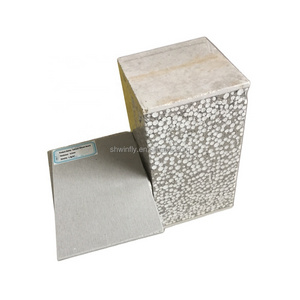

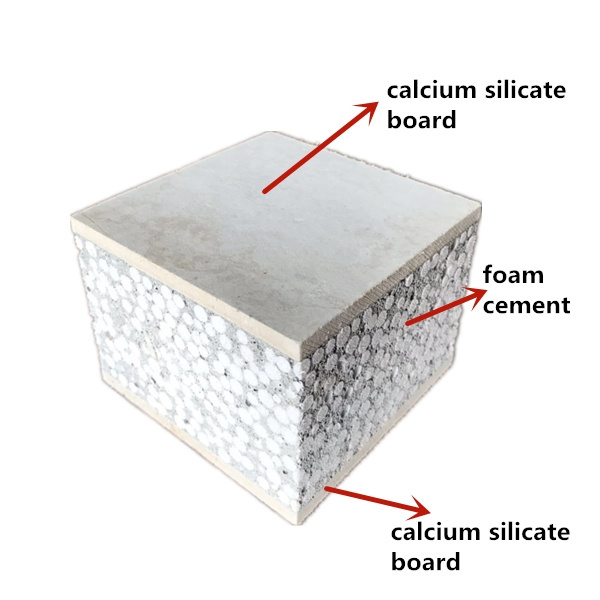

Sanle EPS cement sandwich panel is composed of exterior panels and interior core filling, to form a non-load-bearing light-weight composite wall panel. The exterior panels on both sides are 5mm calcium silicate board, and the middle core is filled with polystyrene beads & cement or ceramsite, polystyrene beads & cement.

Projects :

Physical Property

| Item | Unit | 125mm | 100mm | 75mm | 50mm |

| volume weight | kg/m3 | 680 | |||

| bending failure load | multiple of plate weight | ≥ 5.5 | ≥ 4.0 | ≥ 3.0 | ≥ 1.5 |

| bending strength | Mpa | ≥ 3.5 | |||

| shock resistance | standard sandbags/time | ≥ 5.0 | |||

| moisture content | % | ≤ 8 | ≤ 10 | ||

| dry shrinkage rate | Mm/m | ≤ 0.5 | |||

| softening coefficient | ≥ 0.8 | ||||

| hanging force | N | ≥ 1000 | |||

| thermal conductivity | W(mk) | 0.19 | |||

| combustion performance | grade A | ||||

| fire endurance | H | ≥ 5.0 | ≥ 4.5 | ≥ 4.0 | ≥ 2.5 |

| air heat insulation | dB | ≥ 50 | ≥ 48 | ≥ 45 | ≥ 40 |

| radioactivity | class A materials | ||||

| Environment | 100% free of asbestos, without formaldehyde, benzene and other harmful substances to human body | ||||

Advantages :

1. Good fireproof performance, moisture-proof, corrosion resistance, Environmental protection.

2. Strong and light weight materials suitable for the construction. It's easy of installation and labor cost saving.

3. Thermally efficient rigid foam insulation used as the core material of sandwich panel. Excellent high temperature stability and low temperature application.

4. Widely used as roofing material for steel structure plant, gym, Supermarket, commercial and civilian facilities.