- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1.8*2.5*1.8m

-

Voltage:

-

380V

-

Power:

-

4

-

Applicable Industries:

-

forestry, Wood industry, Furniture Factory

-

Weight (KG):

-

2400

-

Product name:

-

horizontal carbonization furnace

-

Production Capacity:

-

300-3000kg

-

Applicable raw materials:

-

Bamboo, coconut shell, log, rice husk,wood chips, etc.

-

Heat source material:

-

Coal, wood, natural gas, diesel, etc.

-

Carbonization method:

-

Dry distillation carbonization

-

Carbonization time:

-

Decide time based on raw materials

-

aw material size:

-

Within 30cm

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Materials:

-

Carbon Steel

Quick Details

-

Place of Origin:

-

Henan,China

-

Core Components:

-

pipeline, thermometer

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Dimension(L*W*H):

-

1.8*2.5*1.8m

-

Voltage:

-

380V

-

Power:

-

4

-

Applicable Industries:

-

forestry, Wood industry, Furniture Factory

-

Weight (KG):

-

2400

-

Product name:

-

horizontal carbonization furnace

-

Production Capacity:

-

300-3000kg

-

Applicable raw materials:

-

Bamboo, coconut shell, log, rice husk,wood chips, etc.

-

Heat source material:

-

Coal, wood, natural gas, diesel, etc.

-

Carbonization method:

-

Dry distillation carbonization

-

Carbonization time:

-

Decide time based on raw materials

-

aw material size:

-

Within 30cm

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Materials:

-

Carbon Steel

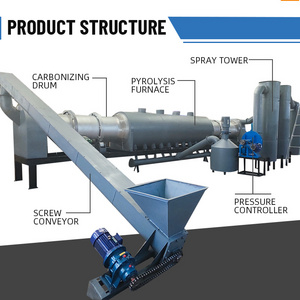

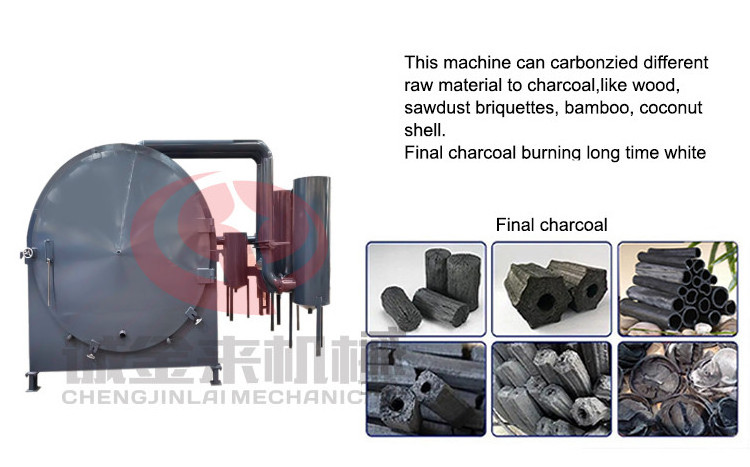

product Description

biochar making machine biochar carbonization furnace charcoal making machine

biochar making machine

range of carbonization furnace includes drying and carbonization of various granular biomass particles such as sawdust particles, olive nucleus and peanut shell. The material is charred into charcoal particles.A flammable gas is generated during the carbonization process, and is returned to the ignition port at the bottom of the carbonization furnace through a pipe to perform secondary combustion.

The feature:

1.

biochar making machine

is the use of horizontal manufacturing process, carbonization furnace has a three-layer structure, and the middle of light insulation materials,It is possible to keep the temperature in the furnace at all times.

2.The door use packing seal, not into the air, Out of carbon than the conventional carbonization furnace is much higher.

3.The reason is called green carbonization furnace because the stick in the carbonization process will produce a lot of light yellow combustible gas. These gases through the carbonization furnace with there own pipes can make combustible gas diversion to the charring furnace combustion zone to the second fire heating. More environmentally friendly and saving fuel.

4. Carbonization furnace excess gas can be used to dry the sawdust or to burn the boiler.

5.Carbonization furnace to end charcoal cooling time is shorter, we use the inter layer of the gap between the unit water cooling carbonization furnace natural cooling, more efficient and convenient.

Carbonization furnace can be customized according to customer requirements.(Materials and working process)

biochar making machine

consists of inner tank, insulation, furnace door, rail car , combustible gas reburning pipe, dehumidifying buffer tank, burner, exhaust pipe, and thermometer. The gasifier and flue gas purification device are the optional machine. This furnace using anaerobic dry distillation principle to remove volatile substances in biomass material, to carbonize the biomass material, carbonization process: Feeding raw material and sealing the furnace→Preheating and drying the raw material → Anaerobic carbonization →Cooling and discharging the carbon, total four steps.

Product Paramenters

Raw material & Final products

Raw Materials: Sawdust, Crops Straw(corn stalk, beanstalk, broomcorn stalk, cotton stalk, rape stalk,palm kernel shell, groundnut stem, sunflower stalk), Husk, Grass, Bush branches, Bamboo butt, Bamboo scraps, Bagasse and so on.

Packing&Shipping

Hot Searches