- Product Details

- {{item.text}}

Quick Details

-

Material:

-

carton

-

Power:

-

none

-

Productivity:

-

1000 Pcs/month

-

Weight (KG):

-

16 kg

-

MembraneChemistry:

-

Polyamide Advanced Nanofiltration Membrane

-

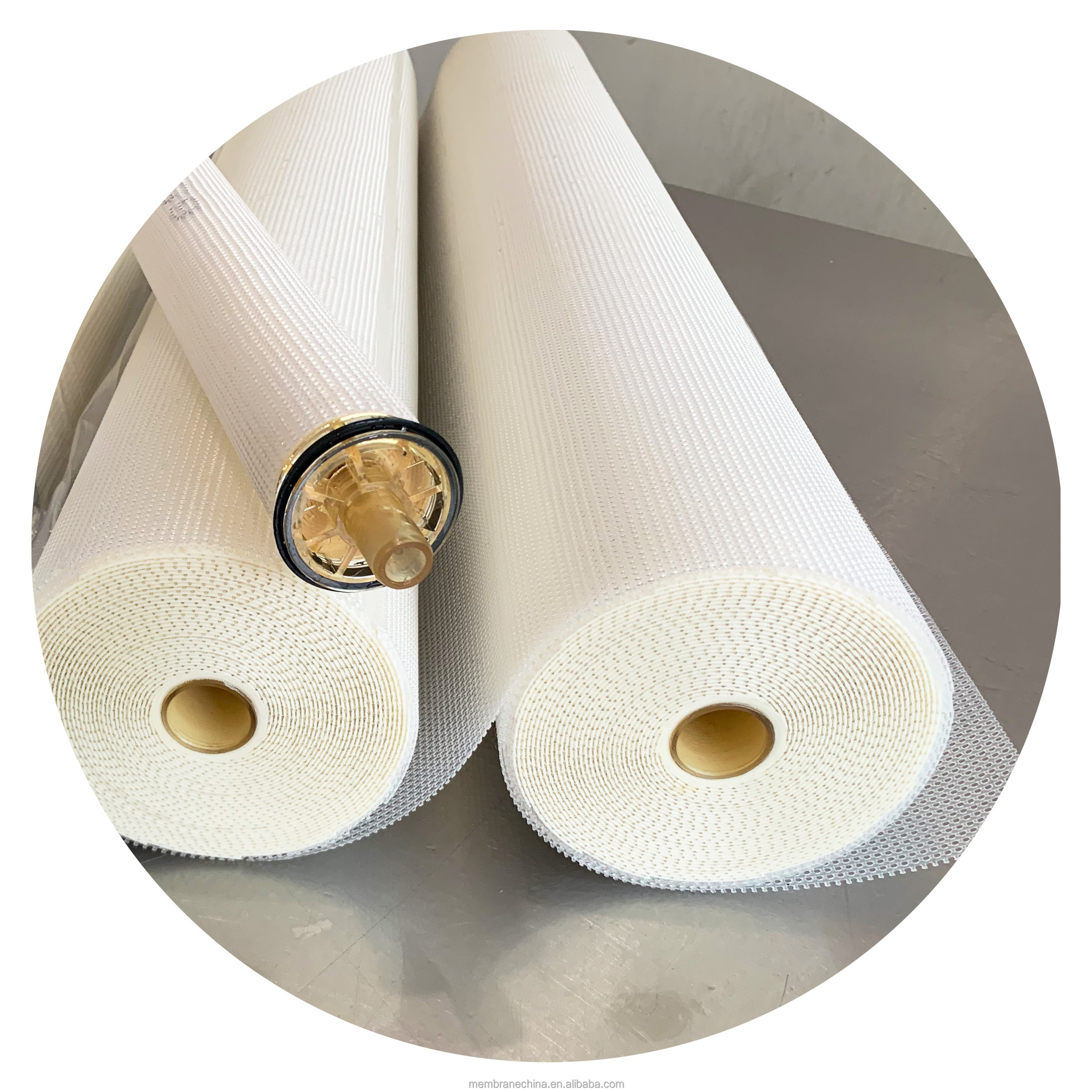

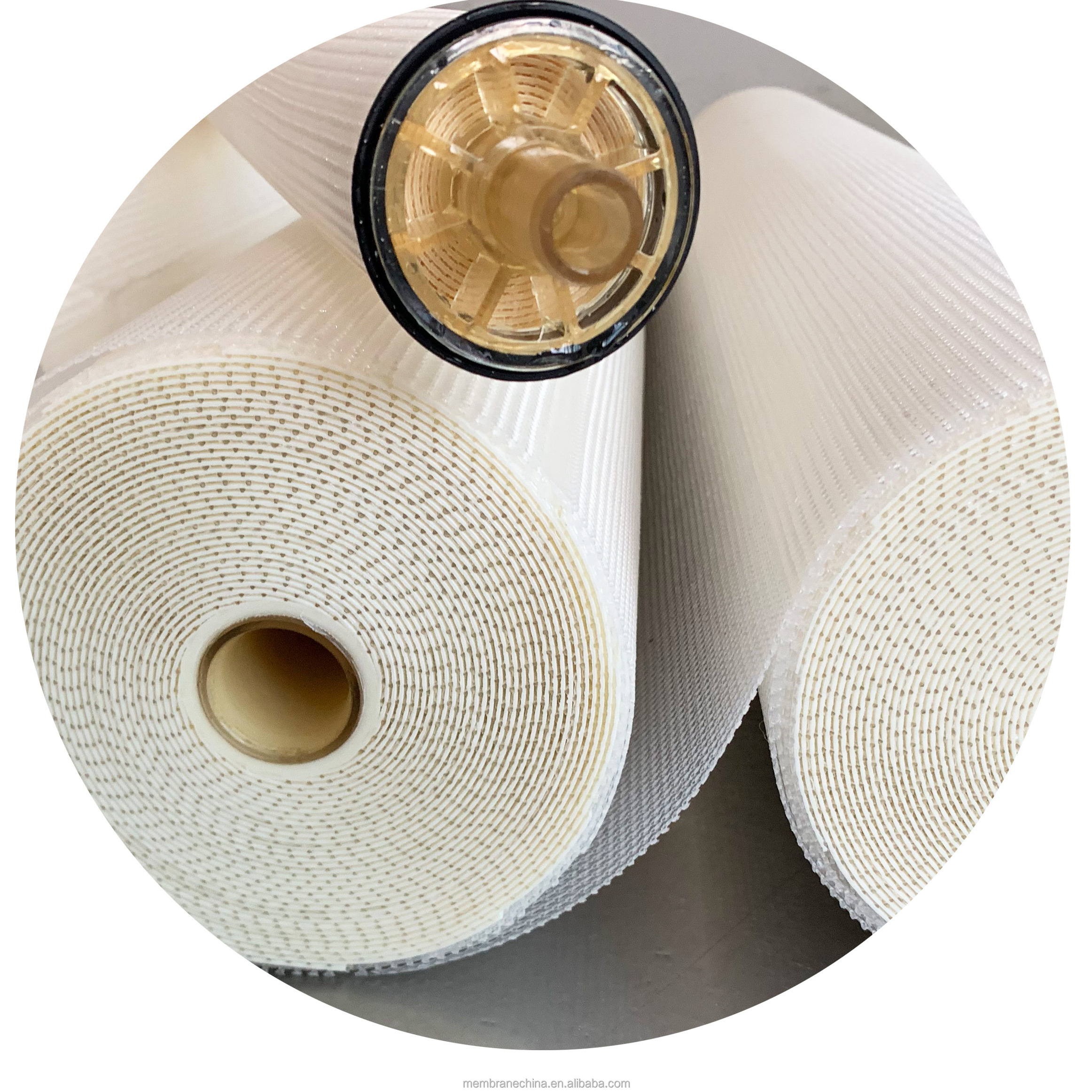

Construction:

-

Spiral wound

-

Outer Wrap:

-

PP net

-

Feed Spacer:

-

F=31MIL

-

Membrane Area:

-

210ft2

-

Flow rate:

-

4800gpd

-

Average Salt Rejection (MgSO4):

-

>99%

-

Average Salt Rejection(NaCl):

-

98.5%

Quick Details

-

Core Components:

-

membrane elements

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

RisingSun Membrane

-

Material:

-

carton

-

Power:

-

none

-

Productivity:

-

1000 Pcs/month

-

Weight (KG):

-

16 kg

-

MembraneChemistry:

-

Polyamide Advanced Nanofiltration Membrane

-

Construction:

-

Spiral wound

-

Outer Wrap:

-

PP net

-

Feed Spacer:

-

F=31MIL

-

Membrane Area:

-

210ft2

-

Flow rate:

-

4800gpd

-

Average Salt Rejection (MgSO4):

-

>99%

-

Average Salt Rejection(NaCl):

-

98.5%

Products Description

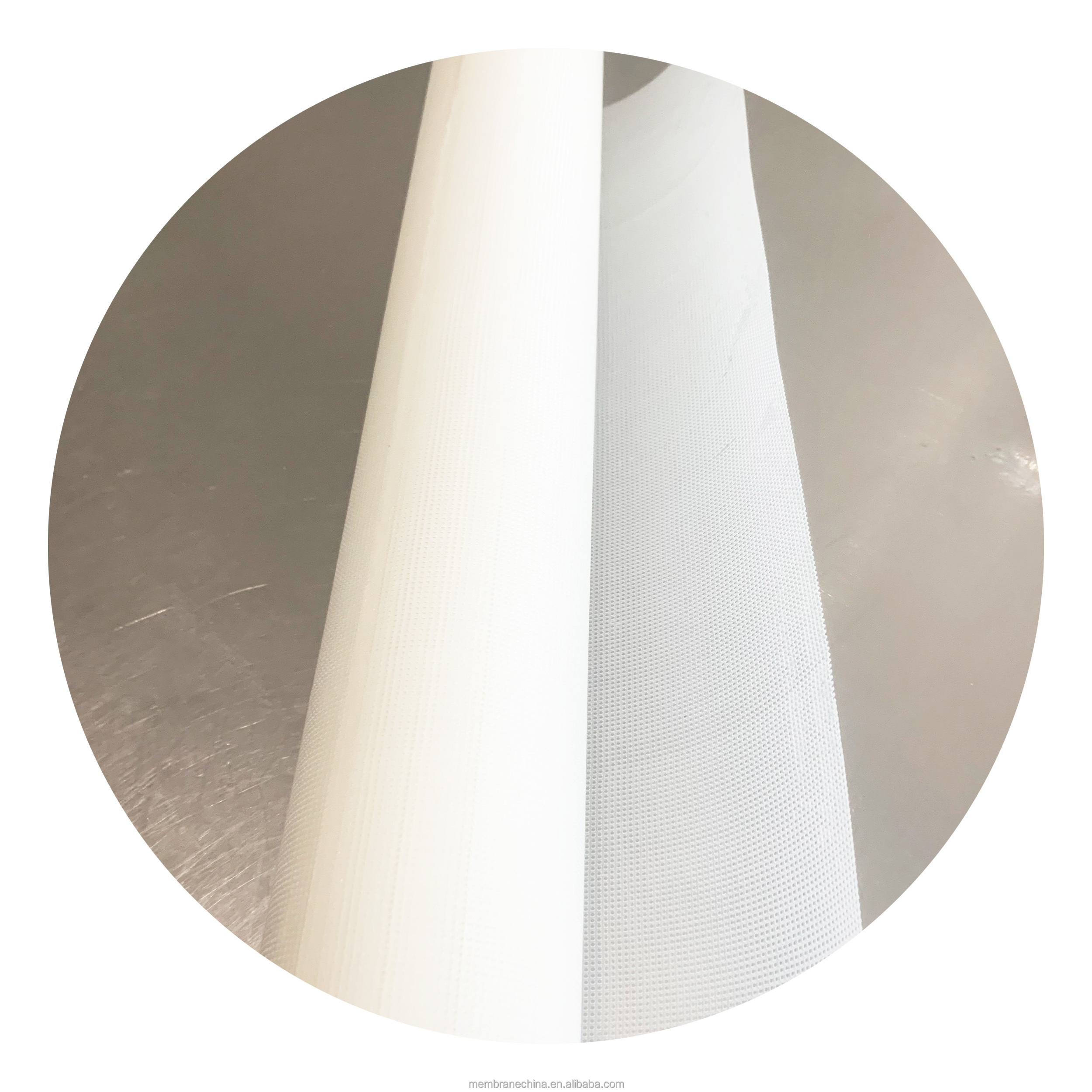

NF Membrane:

NF membranes have a molecular weight cut-off between 150-2000 Dalton usually. RisingSun Membrane manufacture spiral sanitary,

Net-Wrapped NF membrane elements for food process, such as dairy, for simultaneous concentration and partial (monovalent ion)

demineralization, Biotec, Pharma, and other applications.

We offer different dimensions, such as 3838/6338/8038/8040/8338 etc. Full-Fit NF Membrane Elements. They have a compact design and

an optimum surface area to volume ratio. The feed channel height can be varied by the thickness of the feed spacer material (from

13 to 120 mil). This design feature leads to excellent hydrodynamics in combination with low energy demand.

Net-Wrapped NF membrane elements for food process, such as dairy, for simultaneous concentration and partial (monovalent ion)

demineralization, Biotec, Pharma, and other applications.

We offer different dimensions, such as 3838/6338/8038/8040/8338 etc. Full-Fit NF Membrane Elements. They have a compact design and

an optimum surface area to volume ratio. The feed channel height can be varied by the thickness of the feed spacer material (from

13 to 120 mil). This design feature leads to excellent hydrodynamics in combination with low energy demand.

NF Membrane:

>usually

molecular weight cut-off between 150-2000 Dalton

.

>

operation pressure is around 3.5-30 bar.

>

standard size 2540/4040/8040, other size available.

>

membrane chemistry: Polyamide, Sulfonate PES, Sulfonate PS.

>

cross reference: Koch, Hydranautics, Microdyn Nadir, GE, AMI…

|

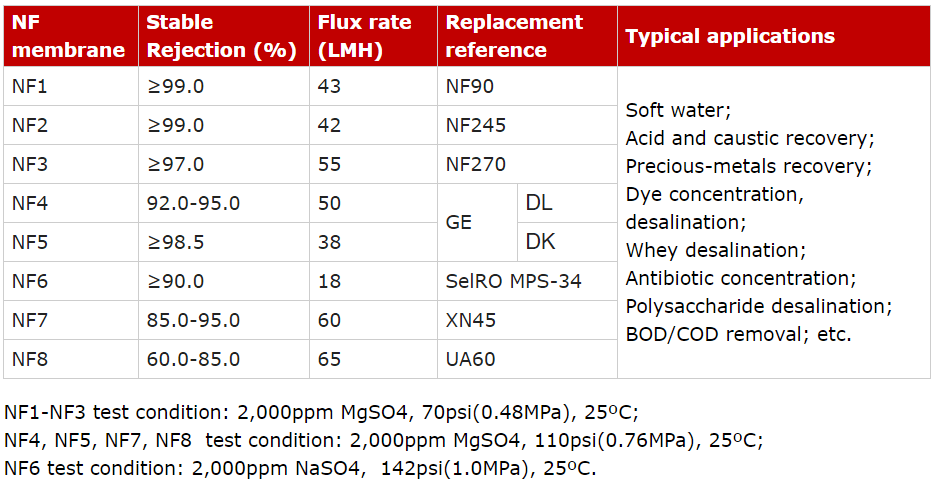

Decoding of Nanofiltration Membrane:

|

|

|

|

|

||||

|

construction

|

Outer Wrap

|

Material Type

|

Size

|

Feed Spacer

|

||||

|

S

piral

|

S

anitary net

G

lass fiber

|

NF1

NF2 NF3 NF4 NF5 … |

2319

2.3"×19"

3838

3.8"×38"

8338

8.3"×38"

8040

8.0"×40"

... ...

|

A

=13mil

F

=31mil

B

=17mil

G

=46mil

C

=20mil

H

=65mil

D

=26mil

I

=80mil

E

=28mil

J

=120mil

|

||||

|

|

|

|

1=Diamond2=Parallel

|

1

=Diamond

2

=Parallel

|

||||

Our Nanofiltration Membrane Sheet Specifications:

Specification:

|

Model

|

Effective Area

|

|

Flow Rate

|

|

Average Salt Rejection (MgSO4)

|

|

Average Salt Rejection (NaCl)

|

|

||||

|

SS-NF2-8038-F

|

370 ft2

|

|

8,600 gpd

|

|

99.0%

|

|

98.5%

|

|

||||

|

SS-NF2-8038-G

|

270 ft2

|

|

6,200 gpd

|

|

99.0%

|

|

98.5%

|

|

||||

|

SS-NF2-8038-H

|

210 ft2

|

|

4,800 gpd

|

|

99.0%

|

|

98.5%

|

|

||||

|

SS-NF2-8038-I

|

189 ft2

|

|

4,300 gpd

|

|

99.0%

|

|

98.5%

|

|

||||

Operation Specification:

|

Typical Operating Pressure:

|

40-200 psi (3.0-14.0 bar)

|

|

Maximum Operating Pressure:

|

600 psi (41 bar)

|

|

Operating Temperature Range:

|

35-113°F (2-45℃)

|

|

Cleaning Temperature Range:

|

113-131°F (45-55℃)

|

|

Allowable pH-Continuous Operation @25℃:

|

2.0-11.0

|

|

Allowable pH-CIP @25℃:

|

1.8-11.5

|

|

Maximum Feed Flow:

|

80 GPM (F); 110 GPM(G); 128 GPM (H); 145 GPM(I)

|

|

Maximum Pressure Drop:

|

13 psi (0.9 bar)

|

|

Maximum SDI ( 15 minutes):

|

5

|

|

Chlorine Tolerance:

|

<0.1 ppm

|

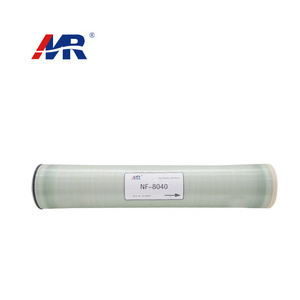

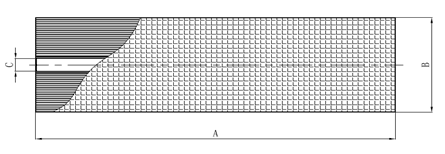

Dimension:

|

Model

|

A

|

|

B

|

|

C

|

|

|||

|

|

inches

|

(mm)

|

inches

|

(mm)

|

inches

|

(mm)

|

|||

|

SS-NF1-8038

|

38.0

|

(965)

|

7.9

|

(200)

|

1.125

|

(28.6)

|

|||

Application:

Water softening

Precious metal recovery

Concentration of protein, amino acid, vitamin in food, beverage and pharmaceutical industry

Acid/caustic recycling

Dye color removal

Heavy metal separation of waste water

Removal of natural organic matter in water and wastewater treatment

Reduction of hardness in water purification

Sulfate removal from seawater and chemical processes

Desalting of process streams in various industries

Precious metal recovery

Concentration of protein, amino acid, vitamin in food, beverage and pharmaceutical industry

Acid/caustic recycling

Dye color removal

Heavy metal separation of waste water

Removal of natural organic matter in water and wastewater treatment

Reduction of hardness in water purification

Sulfate removal from seawater and chemical processes

Desalting of process streams in various industries

Replacements Reference

|

RisingSun Membrane

|

Other Brands

|

RisingSun Membrane

|

Other Brands

|

|

|

SG-NF1-2540

|

DOW NF90-2540

|

SG-NF4-2540-F1

|

Trisep 2540-XN45

|

|

|

SG-NF1-4040

|

DOW NF90-4040

|

SG-NF4-2540-G2

|

GE DL2540F50

|

|

|

SG-NF1-8040

|

DOW NF90-400

|

SG-NF4-4040-F1

|

Trisep 4040-XN45

|

|

|

|

|

SG-NF4-4040-G2

|

GE DL4040F50

|

|

|

SS-NF2-3838-F1

|

DOW NF245-3838/30-FF

|

SG-NF4-8040-F1

|

Trisep 8040-XN45

|

|

|

SS-NF2-3840-F1

|

DOW NF245-3840/30-FF

|

SG-NF4-8040-G2

|

GE DL8040F50

|

|

|

SS-NF2-8040

|

DOW NF245-390-FF

|

|

|

|

|

|

|

SG-NF5-2540-F1

|

GE DK2540F1072

|

|

|

SG-NF3-4040

|

DOW NF270-4040

|

SG-NF5-2540-G2

|

GE DK2540F1073

|

|

|

SG-NF3-8040

|

DOW NF270-400

|

SG-NF5-4040-F1

|

GE DK4040F1020

|

|

|

|

|

SG-NF5-4040-G2

|

GE DK4040F1021

|

|

|

SS-NF6-4040

|

GE HL4040F

|

SG-NF5-8040-F1

|

GE DK8040F1001

|

|

|

SS-NF6-8040

|

GE HL8040F

|

SG-NF5-8040-G2

|

GE DK8040F1002

|

|

FAQ

1, Q: Are you manufacturer?

A:Yes, definitely,our factory locate in Beijing,China.

2, Q:What's your main products ?

A: we manufactur filter membranes, RO, NF, UF, MF membrane, spiral wound/flat sheet membrane, tubular membrane, MBR, DTRO,

STRO,E-coat UF membrane, anode cell etc.

3, Q: what's your main market?

A:There're about 94 countries we've been exported, mainly in USA, Korea, UK, France, Russia, Germany, India, Spain, Brazil etc.

4, Q:Can you supply free sample?

A:Yes, we can supply free samples which are in stock, and the freight charge should be on your side.

5, Q: What about the package?

A:The membrane elements are wrapped with plastic bubble paper, then carton box, safe wooden box outise, the breakage is less than

1%.

6, Q: Do you offer OEM?

A: Sure!

A:Yes, definitely,our factory locate in Beijing,China.

2, Q:What's your main products ?

A: we manufactur filter membranes, RO, NF, UF, MF membrane, spiral wound/flat sheet membrane, tubular membrane, MBR, DTRO,

STRO,E-coat UF membrane, anode cell etc.

3, Q: what's your main market?

A:There're about 94 countries we've been exported, mainly in USA, Korea, UK, France, Russia, Germany, India, Spain, Brazil etc.

4, Q:Can you supply free sample?

A:Yes, we can supply free samples which are in stock, and the freight charge should be on your side.

5, Q: What about the package?

A:The membrane elements are wrapped with plastic bubble paper, then carton box, safe wooden box outise, the breakage is less than

1%.

6, Q: Do you offer OEM?

A: Sure!

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches