- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tuotian Bailey Bridge

-

Model Number:

-

CB100 CB200

Quick Details

-

Grade:

-

Steel

-

Tolerance:

-

±3%

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Tuotian Bailey Bridge

-

Model Number:

-

CB100 CB200

Products Description

What is Bailey Bridge?

Bailey bridge is a fabricated steel bridge, which is characterized by light components, convenient disassembly and strong adaptability, and can be built quickly with simple tools and manpower.

The early Compact-100 Bailey Bridge was mainly used in the military, that is, military steel bridge. Now Compact-100 Bailey Bridge has been widely used in rescue and disaster relief, traffic engineering, municipal water conservancy engineering, dangerous bridge reinforcement, etc. in addition to being a war-ready steel bridge.

For example, during the 5.12 Wenchuan earthquake in 2008, a large number of Bailey Bridges were used for rescue and disaster relief. Bailey Bridges played a key role in transport of earthquake relief materials, evacuation of the wounded and evacuation of the masses.

The compact 200 Bailey bridge is an upgraded steel structure prefabricated bridge based on the compact 100 Bailey bridge. The appearance is similar to the compact 100-type Bailey bridge. The height of the truss is increased from 1.448 meters to 2.134 meters, and the load-bearing capacity and strength have been increased. Therefore, it is more suitable for use under heavy load. The 200-type compact Bailey bridge supports two lanes, which greatly expands the scope of use of the bridge.

|

Surface treatment

|

Painting, Galvanized

|

|

Color

|

Green, , Customize

|

|

Material

|

Q235B, Q345B, Q355B

|

|

Orginal

|

Hunan, China

|

|

Certificate

|

ISO9001

|

|

Product name:

|

Compact-100 Bailey Bridge

|

|

Model alias:

|

321-type prefabricated highway steel bridge (Bailey Bridge)

|

|

Derivative models:

|

CB100, Compact-100, British 321-Type Bailey Bridge.

|

|

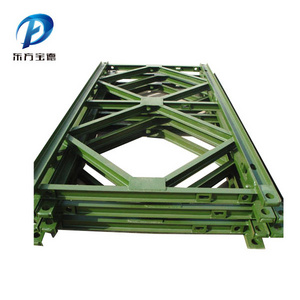

Truss piece model:

|

Type 321 Bailey Panel

|

|

Conventional size of truss piece:

|

3 meters × 1.4 meters (hole to hole) usually also said: 3 meters X 1.5 meters (side to side)

|

|

Maximum span of steel bridge design:

|

51-meter single-span (if the total length is greater than 51 meters, it can be used as a multi-span continuous beam, and 200-type, GWD-type steel bridge can also be selected)

|

|

Standard lane width of steel bridge:

|

4.2 meters single lane (also can be customized according to customer needs)

|

|

Load class:

|

Class 10 for automobiles; Class 15 for automobiles; Class 20 for automobiles; Class 50 for crawlers; Class 80 for trailers; 40

tons for bicycles; AASHTO HS20, HS25-44, HL93, BS5400 HA + HB; City-A; City-B; Highway-I; Highway-II; Indian standard Class-40; Australian standard T44; Korean standard D24, etc. |

|

Design:

|

321 type SS, SSR, DS, DSR, TS, TSR, DD, DDR

According to the difference of span and load, select the appropriate row. Contact us for free design. |

|

Main material of steel bridge:

|

GB Q355B

|

|

Connecting bolt grade:

|

8.8 high-strength bolts

|

|

Surface corrosion:

|

Hot-dip galvanizing; paint; heavy-duty anti corrosive paint for steel structure; anti-skid aggregate treatment of bridge deck, etc.

|

|

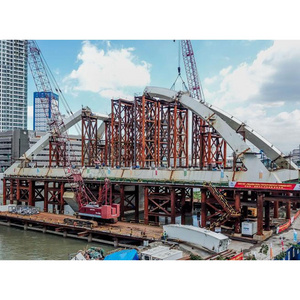

Bridge erection method:

|

Cantilever push-out method; hoisting method; floating method; in-situ assembly method; soil pile construction method, etc.

|

|

Installation takes time:

|

7-14 sunny days after the abutment and other conditions are met (determined according to the length of the bridge and site

conditions) |

|

Installation requires workers:

|

6-8 (determined according to site conditions)

|

|

Equipment required for installation:

|

Cranes, hoists, jacks, chain hoists, etc. (Can be adjusted according to site conditions)

|

|

Steel bridge features:

|

lightweight components,easy disassembly and assembly,wide range of applications

|

|

Pass the certification:

|

ISO,etc.

|

|

Annual output:

|

12000 tons

|

|

Product name:

|

Compact-200 Bailey Bridge

|

|

Model alias:

|

200-type prefabricated highway steel bridge (Bailey Bridge)

|

|

Derivative models:

|

CB200-type, HD200-type Bailey Bridge.

|

|

Truss piece model:

|

Type 200 Bailey Panel

|

|

Conventional size of truss piece:

|

3048mm*2134mm(hole centre distance)

|

|

Maximum span of steel bridge design:

|

Single Lane Maximum Allowable Span 60.96m

Double lane Maximum Allowable Span 45.72M

If the total length is greater than the maximum allowable span,it can be used as a multi-spam continuous beam.

|

|

Standard lane width of steel bridge:

|

Net width of bridge deck:

Standard single lane 3.15m

Extra width single lane 4.2m

Standard double lane 7.35m

|

|

Load class:

|

Class 10 for automobiles; Class 15 for automobiles; Class 20 for automobiles; Class 50 for crawlers; Class 80 for trailers; 40

tons for bicycles; AASHTO HS20, HS25-44, HL93, BS5400 HA + HB; City-A; City-B; Highway-I; Highway-II; Indian standard Class-40; Australian standard T44; Korean standard D24, etc. |

|

Design:

|

321 type SS, SSR, DS, DSR, TS, TSR, DD, DDR

According to the difference of span and load, select the appropriate row. Contact us for free design. |

|

Main material of steel bridge:

|

GB Q355B

|

|

Connecting bolt grade:

|

8.8 high-strength bolts

|

|

Surface corrosion:

|

Hot-dip galvanizing; paint; heavy-duty anti corrosive paint for steel structure; anti-skid aggregate treatment of bridge deck, etc.

|

|

Bridge erection method:

|

Cantilever push-out method; hoisting method; floating method; in-situ assembly method; soil pile construction method, etc.

|

|

Installation takes time:

|

7-14 sunny days after the abutment and other conditions are met (determined according to the length of the bridge and site

conditions) |

|

Installation requires workers:

|

6-8 (determined according to site conditions)

|

|

Equipment required for installation:

|

Cranes, hoists, jacks, chain hoists, etc. (Can be adjusted according to site conditions)

|

|

Steel bridge features:

|

lightweight components,easy disassembly and assembly,wide range of applications

|

|

Pass the certification:

|

ISO,etc.

|

|

Annual output:

|

12000 tons

|

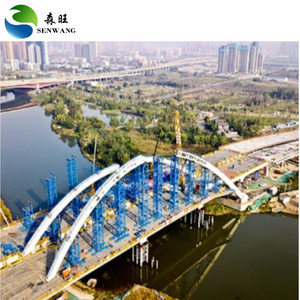

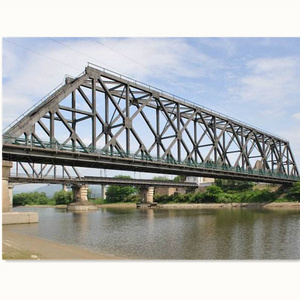

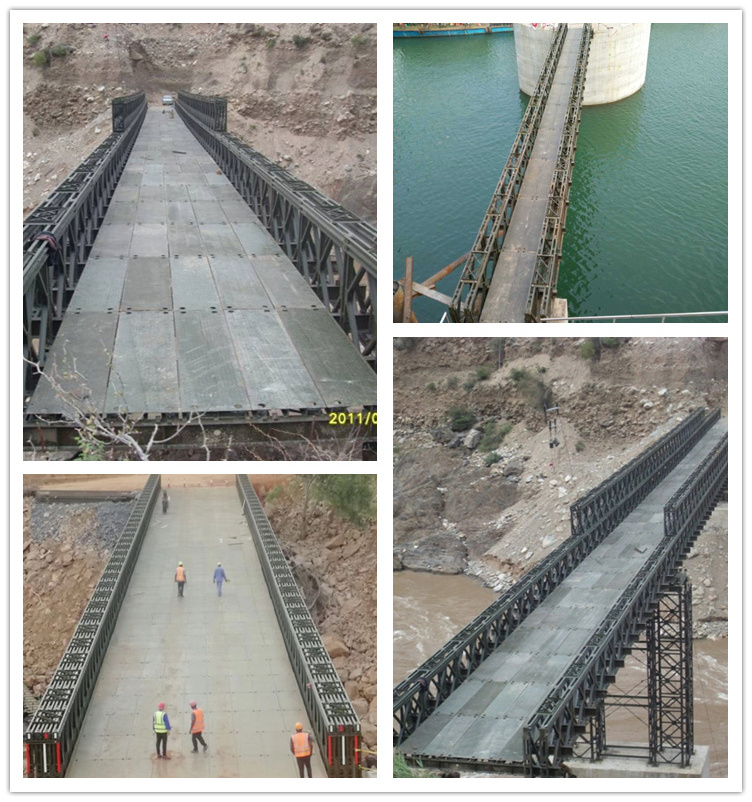

Cases

Customer Photos

Product packaging

Hot Searches