- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

150 mm

-

Brand Name:

-

Darling Machinery

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6500 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V sheet metal cutting machine

-

Dimension(L*W*H):

-

3840x1610x1650mm

-

Name:

-

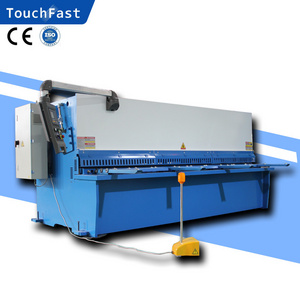

sheet metal cutting machine

-

Color:

-

Blue White sheet metal cutting machine

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Cutting thickness:

-

0-100mm sheet metal cutting machine

-

Cutting length:

-

0-6000mm sheet metal cutting machine

-

Application:

-

Industrial Metal Cutting

-

Control system:

-

E21 Estun sheet metal cutting machine

-

Type:

-

Swing Beam Shear sheet metal cutting machine

-

Backgauge range:

-

20-800mm sheet metal cutting machine

-

Keyword:

-

sheet metal cutting machine

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

6 mm

-

Shearing Angle:

-

1"30

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

150 mm

-

Brand Name:

-

Darling Machinery

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6500 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V sheet metal cutting machine

-

Dimension(L*W*H):

-

3840x1610x1650mm

-

Name:

-

sheet metal cutting machine

-

Color:

-

Blue White sheet metal cutting machine

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Cutting thickness:

-

0-100mm sheet metal cutting machine

-

Cutting length:

-

0-6000mm sheet metal cutting machine

-

Application:

-

Industrial Metal Cutting

-

Control system:

-

E21 Estun sheet metal cutting machine

-

Type:

-

Swing Beam Shear sheet metal cutting machine

-

Backgauge range:

-

20-800mm sheet metal cutting machine

-

Keyword:

-

sheet metal cutting machine

guillotine shear QC12K 6X3200mm stainless sheet metal cutting shearing machine

Video link:

YouTube: https://youtu.be/ya8VmHqORqA

QQ video: https://v.qq.com/x/page/k3215hu5ul0.html

Baidu video: https://haokan.baidu.com/v?vid=3844352724008884888&bfe=1

T echnical P arameters

|

Model |

Max.cutting thickness (mm) |

Max. Cutting width (mm) |

Shearing angle ( ° ″ ) |

Strokes (times/min) |

Back gauge (mm) |

Main power (KW) |

weight (kg) |

Dimension (L x W x H) mm |

|

QC12Y-4x2500 |

4 |

2500 |

1° 30″ |

≥18 |

20-600 |

4 |

4200 |

3040x1610x1650 |

|

QC12Y-4x3200 |

4 |

3200 |

1° 30″ |

≥14 |

20-600 |

5.5 |

5500 |

3840x1610x1650 |

|

QC12Y-4x4000 |

4 |

4000 |

1° 30″ |

≥10 |

20-600 |

5.5 |

6500 |

4640x1705x1700 |

|

QC12Y-4x6000 |

4 |

6000 |

1° 30″ |

≥10 |

20-600 |

7.5 |

15000 |

6460x2100x3200 |

|

QC12Y-6x2500 |

6 |

2500 |

1° 30″ |

≥18 |

20-600 |

7.5 |

5200 |

3140x1610x1650 |

|

QC12Y-6x3200 |

6 |

3200 |

1° 30″ |

≥14 |

20-600 |

7.5 |

6500 |

3840x1610x1650 |

|

QC12Y-6x4000 |

6 |

4000 |

1° 30″ |

≥10 |

20-600 |

7.5 |

7500 |

4640x1705x1700 |

|

QC12Y-6x5000 |

6 |

5000 |

1° 30″ |

≥10 |

20-750 |

11 |

13500 |

5786x2200x2160 |

|

QC12Y-6x6000 |

6 |

6000 |

1° 30″ |

≥7 |

20-800 |

15 |

17000 |

6900x2570x2280 |

|

QC12Y-8x2500 |

8 |

2500 |

1° 30″ |

≥14 |

20-600 |

11 |

5800 |

3040x1610x1650 |

|

QC12Y-8x3200 |

8 |

3200 |

1° 30″ |

≥10 |

20-600 |

11 |

6800 |

3840x1610x1650 |

|

QC12Y-8x4000 |

8 |

4000 |

1° 30″ |

≥8 |

20-600 |

11 |

8500 |

4860x1705x1700 |

|

QC12Y-8x5000 |

8 |

5000 |

1° 30″ |

≥7 |

20-750 |

15 |

15000 |

5786x2252x2310 |

|

QC12Y-8x6000 |

8 |

6000 |

1° 30″ |

≥5 |

20-750 |

18.5 |

18000 |

6900x2570x2280 |

|

QC12Y-10x2500 |

10 |

2500 |

1° 30″ |

≥11 |

20-600 |

15 |

6500 |

3350x2050x1950 |

|

QC12Y-10x3200 |

10 |

3200 |

1° 30″ |

≥10 |

20-600 |

15 |

7400 |

4050x2050x1950 |

|

QC12Y-10x4000 |

10 |

4000 |

1° 30″ |

≥12 |

20-600 |

18.5 |

12500 |

4800x2200x2100 |

|

QC12Y-10x6000 |

10 |

6000 |

1° 30″ |

≥10 |

20-800 |

18.5 |

22000 |

6900x2570x2280 |

|

QC12Y-12x2500 |

12 |

2500 |

1° 30″ |

≥11 |

20-600 |

18.5 |

9500 |

3350x2050x1950 |

|

QC12Y-12x3200 |

12 |

3200 |

1° 30″ |

≥10 |

20-800 |

18.5 |

11500 |

4020x2050x2230 |

|

QC12Y-12x4000 |

12 |

4000 |

1° 30″ |

≥8 |

20-800 |

18.5 |

13500 |

4820x2400x2730 |

|

QC12Y-12x5000 |

12 |

5000 |

1° 30″ |

≥7 |

20-800 |

22 |

18000 |

5600x2500x2000 |

|

QC12Y-12x6000 |

12 |

6000 |

1° 30″ |

≥6 |

20-800 |

22 |

19000 |

6900x2570x2280 |

|

QC12Y-16x2500 |

16 |

2500 |

2° |

≥8 |

20-800 |

18.5 |

11500 |

3520x2060x2350 |

|

QC12Y-16x3200 |

16 |

3200 |

2° |

≥7 |

20-800 |

22 |

13500 |

4062x2300x2320 |

|

QC12Y-16x4000 |

16 |

4000 |

2° |

≥5 |

20-800 |

22 |

16000 |

4850x2350x2300 |

|

QC12Y-16x5000 |

16 |

5000 |

2° |

≥5 |

20-800 |

22 |

25000 |

5900x2600x2700 |

|

QC12Y-16x6000 |

16 |

6000 |

2° |

≥5 |

20-800 |

22 |

36800 |

6900x2700x2700 |

|

QC12Y-20x2500 |

20 |

2500 |

2° 30″ |

≥6 |

20-800 |

37 |

18000 |

3400x2088x2570 |

|

QC12Y-20x3200 |

20 |

3200 |

2° 30″ |

≥5 |

30-800 |

37 |

23000 |

4150x2350x2710 |

|

QC12Y-20x4000 |

20 |

4000 |

2° 30″ |

≥5 |

30-1000 |

37 |

19000 |

4920x2400x2730 |

|

QC12Y-20x5000 |

20 |

5000 |

2° 30″ |

≥4 |

20-800 |

37 |

25000 |

5900x3000x3300 |

|

QC12Y-20x6000 |

20 |

6000 |

2° 30″ |

≥4 |

20-800 |

37 |

47000 |

6700x3000x3000 |

|

QC12Y-25x2500 |

25 |

2500 |

3° |

≥5 |

30-800 |

45 |

19000 |

3500x2400x2500 |

|

QC12Y-25x3200 |

25 |

3200 |

3° |

≥4 |

30-800 |

45 |

22000 |

4200x2400x2500 |

|

QC12Y-25x4000 |

25 |

4000 |

3° |

≥4 |

30-800 |

45 |

26000 |

4950x2500x2600 |

|

QC12Y-30x2500 |

30 |

2500 |

3° |

≥4 |

30-800 |

37 |

28000 |

3300x2900x3000 |

|

QC12Y-30x3200 |

30 |

3200 |

3° 30″ |

≥4 |

30-800 |

45 |

34000 |

4200x2500x2600 |

|

QC12Y-40x2500 |

40 |

2500 |

4° |

≥3 |

30-800 |

75 |

46000 |

3200x3300x3200 |

|

QC12Y-40x3200 |

40 |

3200 |

4° |

≥3 |

30-800 |

90 |

58000 |

4300x3300x3000 |

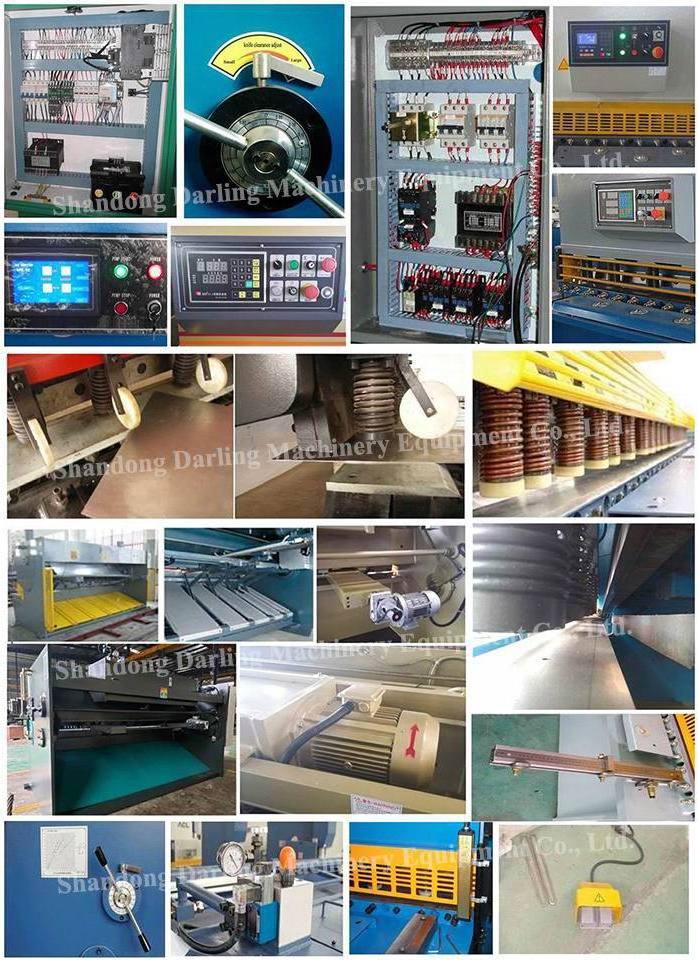

M ain configuration

1, electric control parts is manufactured by Schneider.

2, cylinder main sealing parts is manufactured by VALQUA of Japan.

3, hydraulic system is cartridge valve control, main part of hydraulic is manufactured by HOERBIGER of Germany.

4, cutting knife is manufactured by Shanghai brand (shang knife) 6CrW2Si.

5, hydraulic pump standard is space technology, lower noise gear pump NT3 series.

6, line guide and ball screw guide is supplied by HIWIN of Taiwan.

7, hydraulic system joint is EMB of Germany, which keep hydraulic system steady working.

Our service

1, before sales: we will give you professional instruction and help you to buy the suitable machine, after you choose our machine, let you take the biggest profit through using our machine.

2, in sales: we will give you feedback informations about your order through photos and video. let you put your heart into stomach.

3, after sales: we will go to your factory to give you a training and teach you how to use our machine, or we will give you a video training. if there is our local agent and office, we will let our local engineer to your factory and give you a training.

4, our quality assurance: all our machine using life.

Getting Local office support, please contact with our company:

|

Shandong Darling Machinery Equipment Co., Ltd.

Add: Shacun Industry Park, Licheng District, Jinan City, China. Contact person: Martin Hoo +86-15253156158 (WhatsApp) Skype/Wechat: martinhoo936 QQ: 613252158 Website: www.darlingmachinery.com |

We will be the best partner

Although we live in different countries, our hearts are always together . We don ’ t only sell machine, we also sell service, technology and brand. One time cooperation, be friend forever!

Our cooperation is Double win results.

® Our aim is:

Through using our machine, you can make better product and earn more money !

FAQ:

1, are you manufacture or trading company?

we are manufacture more than 15 years, 3 branch factory, more than 10000 square meters.

2, how about your quality ?

we only sell high quality machine, we use the world famous brand component, like SIEMENS, MITSUBISHI, DELEM, PANASONIC, SCHNEIDER, ABB, etc. so there is no worry about our quality.

3, what about your after sales service ?

we go to your factory for site training or you can get local branch company traning, if there is no requirement, we can give you video training in other methods.

4, why do we must choose you as our supplier ?

customer real voice is your best reference, 5 stars customer feedback reviews, 100% high praise. those voice can let you to cooperate with us safely.