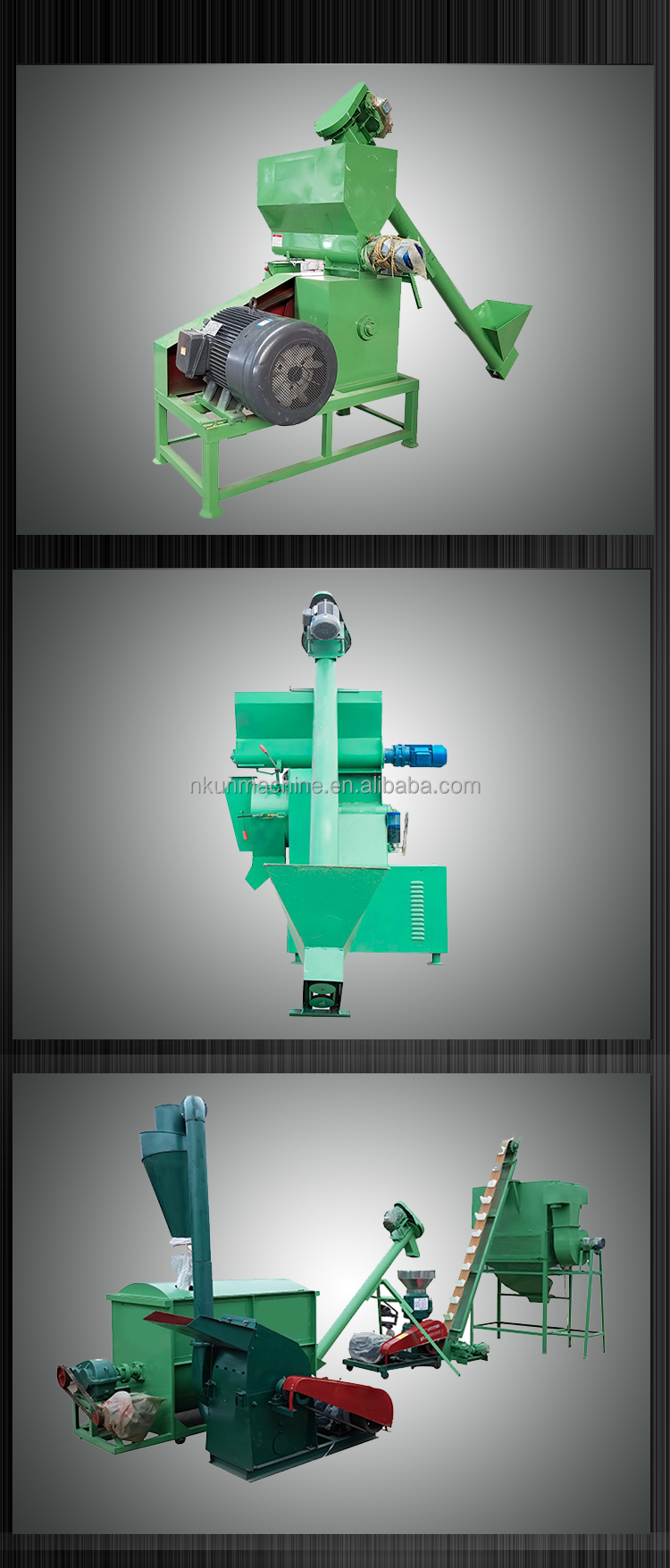

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

/

-

Weight:

-

270 kg

-

Product name:

-

animal feed pellet making line

-

Application:

-

Livestock Farm

-

Function:

-

Aniaml Feed pellet making

-

Raw material:

-

Corn Soybean Wheat

-

Capacity:

-

500kg/1500kg/2000kg

-

Pellet size:

-

3.5/4/5mm

-

Can make feed for:

-

rabbit/chicken/cattle/pig

-

Certification:

-

CE

-

Color:

-

Green

-

Package:

-

Standard Package

Quick Details

-

Max. Capacity:

-

8 ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NKUN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

/

-

Weight:

-

270 kg

-

Product name:

-

animal feed pellet making line

-

Application:

-

Livestock Farm

-

Function:

-

Aniaml Feed pellet making

-

Raw material:

-

Corn Soybean Wheat

-

Capacity:

-

500kg/1500kg/2000kg

-

Pellet size:

-

3.5/4/5mm

-

Can make feed for:

-

rabbit/chicken/cattle/pig

-

Certification:

-

CE

-

Color:

-

Green

-

Package:

-

Standard Package

Products Description

Crumble chicken 5tph pallet feed production line feed mixer machine production line

This unit does not need to add any water to make pellets, it belongs to the kind of dry in

and dry out. When manufacturing, we use it for small-scale farming, and the pellets made at the same time can be stored for a long time, and it is not a problem for more than half a year. At the same time, the feed pellet machine also plays a sterilizing role in the process of operation. The maximum temperature is 80 degrees, which can kill your microbial strains without affecting the

quality of the material.

and dry out. When manufacturing, we use it for small-scale farming, and the pellets made at the same time can be stored for a long time, and it is not a problem for more than half a year. At the same time, the feed pellet machine also plays a sterilizing role in the process of operation. The maximum temperature is 80 degrees, which can kill your microbial strains without affecting the

quality of the material.

Features:

* It has the better raw material versatility.

* Low energy consumption, high production efficiency.

* The dry / wet raw materials can be packed into grains at one time, saving time and effort.

* Low moisture content, better storage.

* Low energy consumption, high production efficiency.

* The dry / wet raw materials can be packed into grains at one time, saving time and effort.

* Low moisture content, better storage.

Product Parameter

|

500kg per hour feed pellet line

|

|

|

|

Type

|

Motor (included)/kw

|

|

|

420 Crusher

|

7.5

|

|

|

500kg Horizontal Mixer

|

4

|

|

|

Screw Conveyor

|

0.75

|

|

|

250 Pellet Machine (flat die)

|

15

|

|

|

Bucket Elevator, Cooler

|

1.1/4

|

|

|

800-1000kg per hour feed pellet line

|

|

|

|

Type

|

Motor (included)/kw

|

|

|

600 Crusher

|

22

|

|

|

1000kg horizontal mixer

|

7.5

|

|

|

330 granulator (flat die with spiral)

250 pellet machine (ring die) |

Conveyor 1.5/22-6

22/0.75 |

|

|

Bucket Elevator, Cooler

|

1.1/4

|

|

|

1500kg per hour feed pellet line

|

|

|

|

Type

|

Motor (included)/kw

|

|

|

50-40 Crusher

|

22-4

|

|

|

1000kg horizontal mixer

|

7.5

|

|

|

400 pellet machine (directly connected flat die)

|

30-6

|

|

|

Bucket Elevator, Cooler

|

1.1/4

|

|

|

2000-2500kg per hour feed pellet line

|

|

|

|

Type

|

Motor (included)/kw

|

|

|

50-50 Crusher

|

30-4

|

|

|

2000kg horizontal mixer

|

11

|

|

|

320 pellet machine (ring die)

|

45-4

|

|

|

Bucket Elevator, Cooler

|

1.1/4

|

|

Main Products

Packing&Delivery

Hot Searches