- Product Details

- {{item.text}}

Quick Details

-

Product size:

-

450*450*100mm

-

Standard:

-

CE

-

Repetitiveness:

-

0.02mm

-

Data memory capacity:

-

999 programs

-

Drive:

-

Stepper motor

-

XYZ axis speed:

-

800mm/s Max

-

Valve driving:

-

2*Double Rod Cylinder

-

Light Source:

-

LED

-

Dimension:

-

1300*1800*1700mm

-

PCB speed:

-

0-5000mm/min

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZCX

-

Weight (KG):

-

800

-

Product size:

-

450*450*100mm

-

Standard:

-

CE

-

Repetitiveness:

-

0.02mm

-

Data memory capacity:

-

999 programs

-

Drive:

-

Stepper motor

-

XYZ axis speed:

-

800mm/s Max

-

Valve driving:

-

2*Double Rod Cylinder

-

Light Source:

-

LED

-

Dimension:

-

1300*1800*1700mm

-

PCB speed:

-

0-5000mm/min

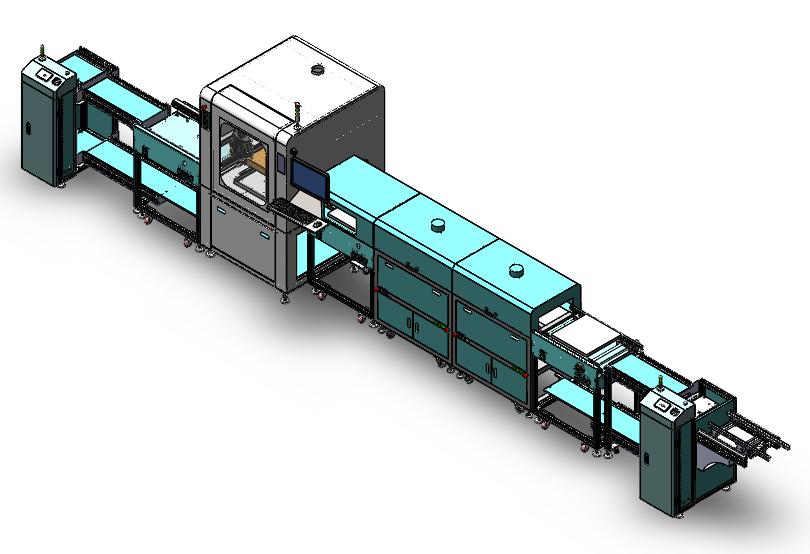

High speed high efficiency spraying online system PCBA automatic adhesive spraying conformal coating machine

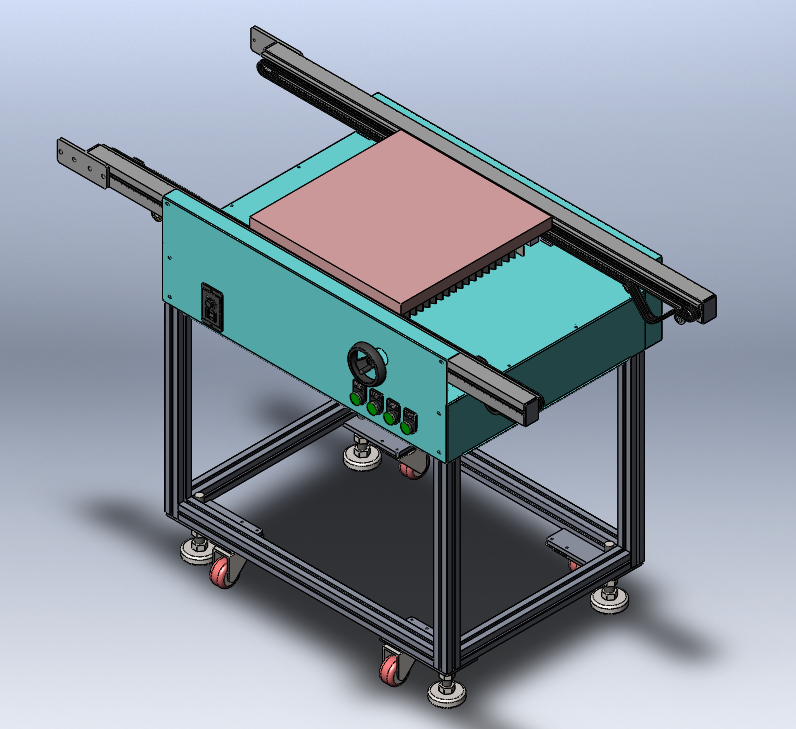

| ITEM | ZCX-PT450A |

| Dimension(L*W*H) | 1300*1800*1700mm |

| Working Platform | T16 Chrome Plate |

| Weight | 850kg |

| Control | PLC+LCD |

| Operating Model | Automatic/PC |

| Programming | Manual |

| Program Storage Quatity | >1000 |

| Track Height | 920±20mm |

| PCB Speed | 0-5000mm/min |

| PCB Direction | L→R (R→L) |

| PCB Width | 50-450mm |

| Speed Control | Automatic Adjustment |

| Driving Method | Stepping Motor+Dual High-precision Screw Rod |

| XY Axis Driving | Servo Motor+High-precision Screw Rod |

| XYZ Axis Speed | 800mm/s Max |

| XYZ Axis Repeatability | 0.01mm |

| Valve Driving | 2*Double Rod Cylinder |

| Valve Quantity | 2 Pcs |

| Valve Type | 1 High-precision Spraying Valve, 1 High-precision Dispensing Valve |

| PCB Size | Max: W450mm*L450mm*H100mm |

| Glue Tank | 10L Stainless Glue Steel Tank(with mixing function) |

| Washing Tank | 1-2L |

| Light Source | LED |

| Detecting Light Source | UV Lighting |

| Power Supply | AC220V 1800W |

| Air Pressure Range | 4-6kgf/cm2 |

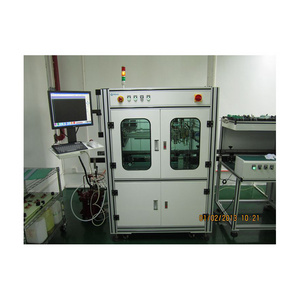

Selective machine is using the high technology to develop, with the unique dispensing valve, make the liquid to be vaporific, evenly dispensing on the PCB. With double-dispensing head, solve the costing difficulty and precise issues. To improve the production and save the costs.

Mainly used in PCB products.

Main features:

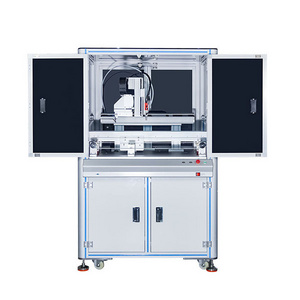

1. The frame is designed with gold sheet metal welding, which has beautiful appearance and stable operation;

2. Using industrial computer control, WINDOWS XP operating system, more convenient and more humane;

3. can be programmed online, or offline programming;

4. With automatic accuracy calibration function, high running accuracy;

5. Controlled by imported pneumatic components;

6. The atomization adjustment adopts a precision pressure regulating valve, which can balance the atomization airflow and improve the edge definition;

7. Unique electric eye installation method can effectively prevent malfunction and extend the service life;

8. Self-contained exhaust emission collection function to better protect the working environment;

9. with low air pressure protection function, can effectively prevent low air pressure and damage the machine and workpiece;

10. The device is equipped with an online automatic signal connection port;

11. Pneumatic adjustment filter has automatic drainage function;

12. With low air pressure alarm function, more secure;

13. UV detection function;

14. High speed and good mute effect, that is, it can work on the jigsaw at the same time, and it can spray the veneer, which is more efficient.

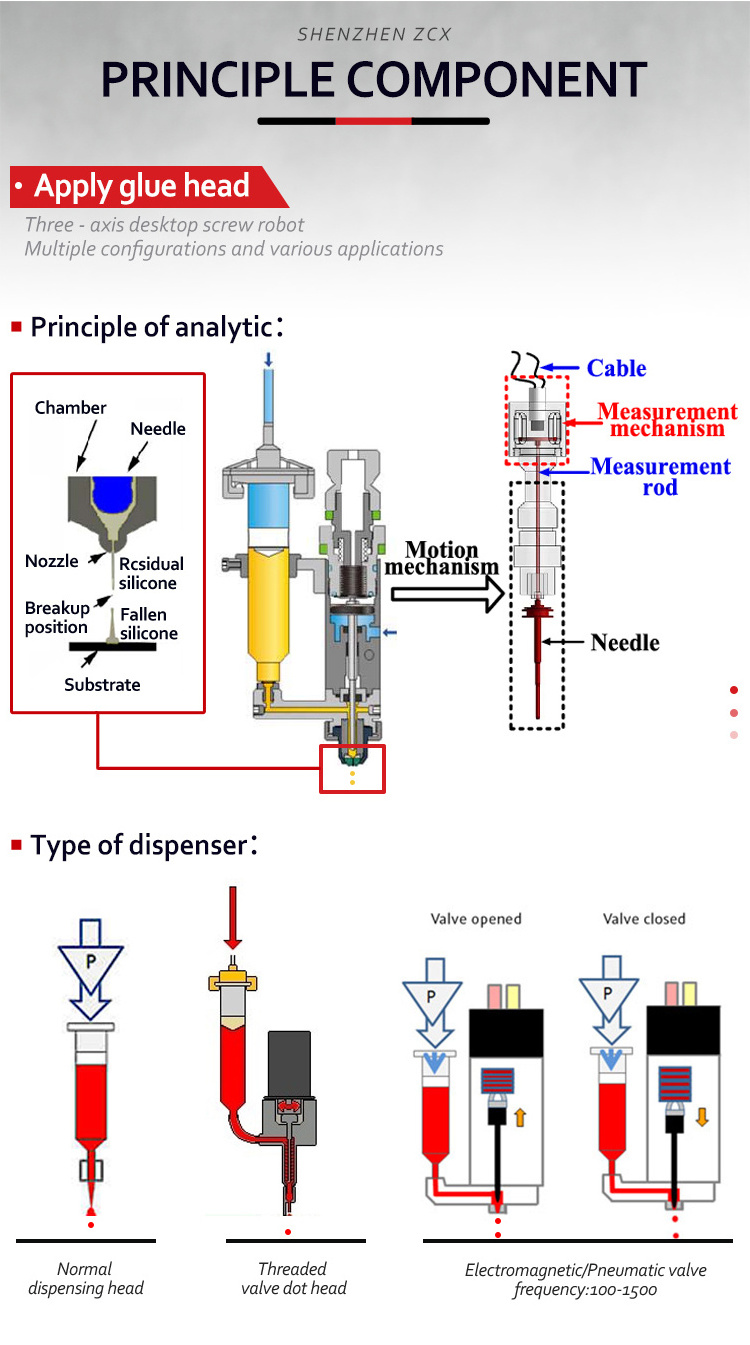

Dispensing valve principle & structure:

There are variaty of configurations for different technique processing. Different glue and glue ratio,substrate,surface, program or dispensing type may effect on the configurations of the machine.

So provide glue TDS to us is important.

1. Plenty options of configurations

2. Fit for various of glue

3. Match for most of processing of production

We have well experienced sales man, please do not hesitate to tell him your requirments, they will provide you the best solution right now!