- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

10*1.3*3.5m

-

Voltage:

-

0

-

Power:

-

0, 22.25kw

-

Weight (KG):

-

8000

-

Product name:

-

Rice Husk Peanut Husk Waste Tree Branch Air Flow Carbonization Furnace

-

Model:

-

HR

-

Capacity:

-

150-200kg

-

Color:

-

Customer Required

-

Raw material:

-

Rice Husk

-

Dimensions:

-

10*1.3*3.5m

-

Effective furnace volume:

-

6-10 cbm

-

Weight:

-

8T

-

Advantage:

-

Continuous Working

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HR

-

Effective Volume:

-

6-10CBM

-

Dimension(L*W*H):

-

10*1.3*3.5m

-

Voltage:

-

0

-

Power:

-

0, 22.25kw

-

Weight (KG):

-

8000

-

Product name:

-

Rice Husk Peanut Husk Waste Tree Branch Air Flow Carbonization Furnace

-

Model:

-

HR

-

Capacity:

-

150-200kg

-

Color:

-

Customer Required

-

Raw material:

-

Rice Husk

-

Dimensions:

-

10*1.3*3.5m

-

Effective furnace volume:

-

6-10 cbm

-

Weight:

-

8T

-

Advantage:

-

Continuous Working

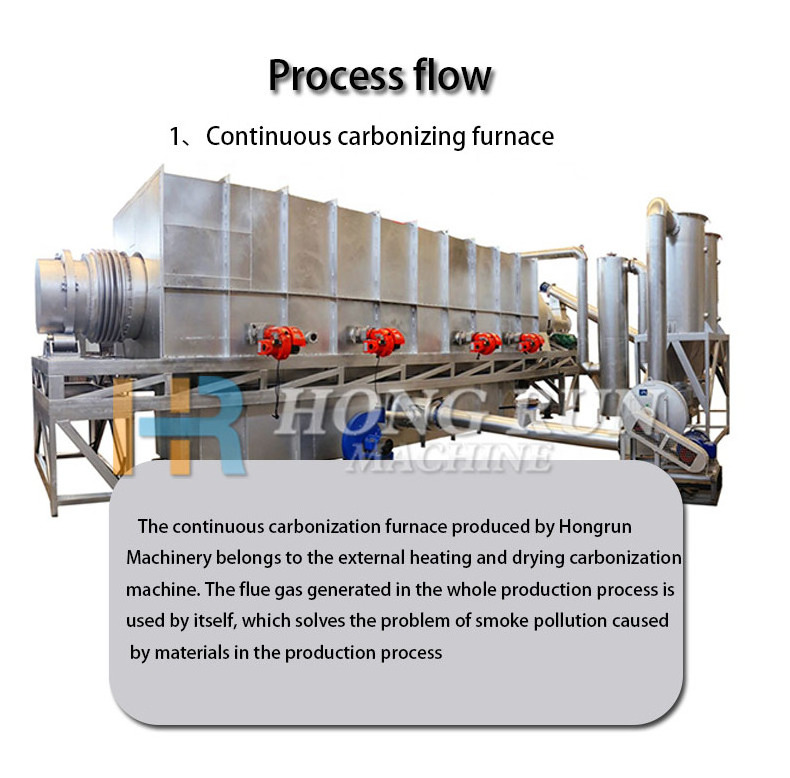

Continuous Rotary Sawdust Carbonization Furnace can carbonize different powder materials into charcoal, such as sawdust, wood chips, rice husk, olive waste, coconut shells, nuts shell,sugarcane bagasse,small things(size: less than 20mm,moisture:15%--20%) . The whole set mainly contains carbonization furnace, gasification furnace, charging part, discharging part, fan, etc.

Gongyi Hongrun energy-saving environment-friendly continuous carbonization machine is a reasonable use of materials in the carbonization process, the production of carbon monoxide, methane, oxygen and other combustible gas recovery, purification, recycling combustion of advanced technology. Both to solve the ordinary carbonization furnace in the carbonization project generated by the smoke on the environment pollution problems, but also to solve the equipment required for thermal problems, fully self-sufficiency, improve the continuity of equipment, economy, environmental protection, energy saving Nature, and efficiency, make full use of agricultural and forestry residues, make it waste into treasure, reduce the contradiction between supply and demand of forestry resources in China, and make more contributions to the green environment.

Continuous Rotary Sawdust Carbonization Furnace can carbonize different powder materials into charcoal, such as sawdust, wood chips, rice husk, olive waste, coconut shells, nuts shell,sugarcane bagasse,small things(size: less than 20mm,moisture:15%--20%) . The whole set mainly contains carbonization furnace, gasification furnace, charging part, discharging part, fan, etc.

The environmentally friendly aluminim cans paint remove furnace uses high temperature to melt the paint

layer of the can to achieve the effect of paint stripping. It can be used to process aluminum cans, aluminum

capacitors, paint cans, and other aluminum wastes. After the paint is stripped, the purity of aluminum during

smelting is improved and profits are increased.

|

Technical parameters of continuous carbonization furnace |

|

|

Model |

HR |

|

Fuel |

F ire wood,nature gas,coal gas,etc |

|

Raw materials |

Sawdust,rice husk, bamboo,coconut shell,wood waste,etc |

|

Furnace dimension |

10*1.3*3.5m |

|

Capacity |

150-200kg |

|

Volume |

6-10 m3 |

|

Power |

22.25KW |

|

Weight |

8T |

Working principle and process of Continuous Rotary Sawdust Carbonization Furnace

Burning the raw material inside of the gasification furnace (as sawdust, shell, Palm shell, husk, straw, wood scrap etc.), the produced flue gas in pipeline within after spray pour, cooling purification, became combustible gas (carbon monoxide, methane, ethane,), as early carbonization of heat, heating and carbonizing the raw material inside of the carbonization furnace(as mechanism core rod, abandoned logs, bark, coconut shell, life garbage,etc.) When the temperature reached to 300 degrees Celsius, carbonization furnace starting carbonizing of raw materials, producing smoke; flue gas become into a combustible gas after spray pour, cooling purification by the cooling purification system, continue carbonizing, then gasifier stop working.

Packing

Shipping

The machine will be shipped with wooden case which has the plastic film inside, and will be delivered in 15 days after receives the payment.