- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

35 %

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Chemical Processing

-

Grade:

-

Nickel Base Alloy, Inconel 625

-

Ni (Min):

-

30%-35%

-

Model Number:

-

Incoloy 800H

-

Brand Name:

-

Fenghua

-

UNS:

-

N06625

-

W.Nr:

-

2.4856

-

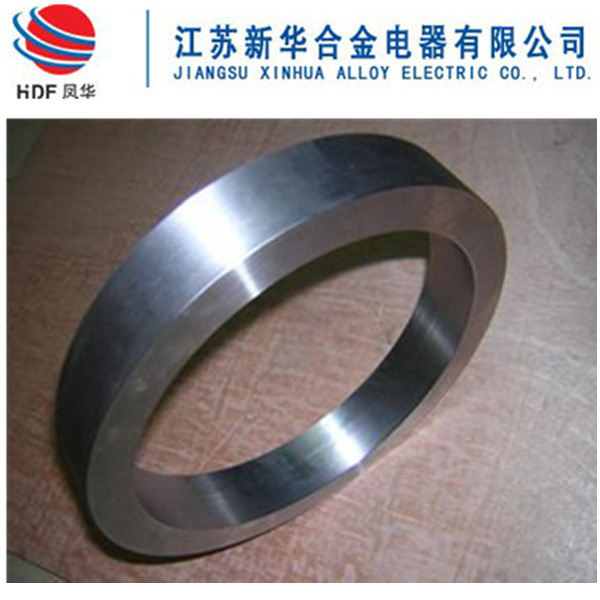

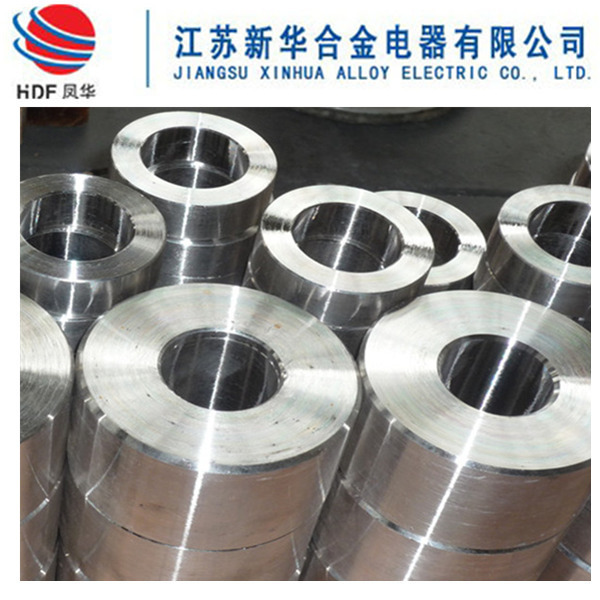

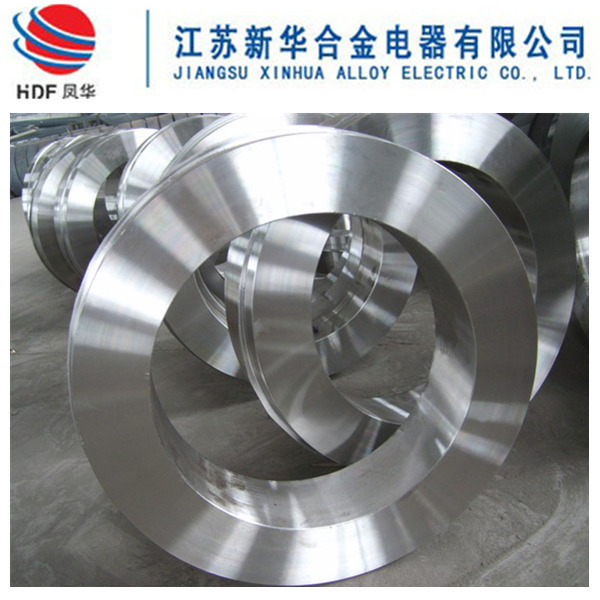

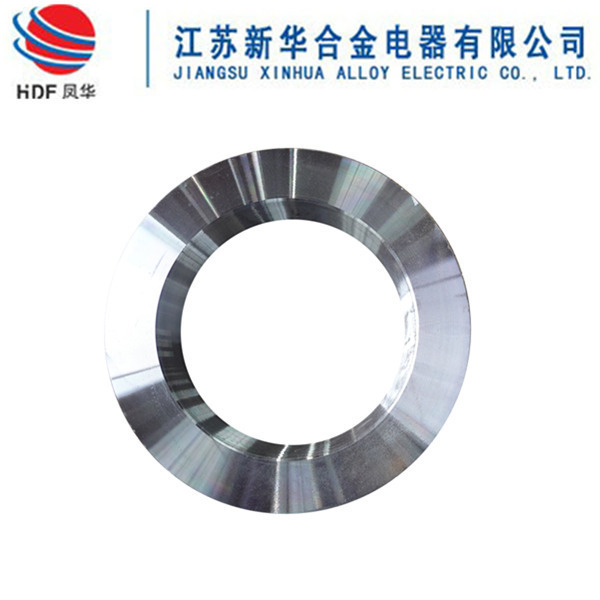

Shape:

-

forging

-

Standard:

-

ASTM

-

Surface:

-

Polished Surface

-

Certificate:

-

SGS ISO9001:2008

-

Name:

-

ASTM B564 Nickel alloy 625 forging

-

Feature:

-

corrosion resistant high level of pitting

-

Material:

-

Nickle Material

Quick Details

-

Resistance (μΩ.m):

-

Stable

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

500

-

Elongation (≥ %):

-

35 %

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Chemical Processing

-

Grade:

-

Nickel Base Alloy, Inconel 625

-

Ni (Min):

-

30%-35%

-

Model Number:

-

Incoloy 800H

-

Brand Name:

-

Fenghua

-

UNS:

-

N06625

-

W.Nr:

-

2.4856

-

Shape:

-

forging

-

Standard:

-

ASTM

-

Surface:

-

Polished Surface

-

Certificate:

-

SGS ISO9001:2008

-

Name:

-

ASTM B564 Nickel alloy 625 forging

-

Feature:

-

corrosion resistant high level of pitting

-

Material:

-

Nickle Material

1.Introduction

Alloy 625 has a high level of pitting and crevive corrosion resistance to chloride contaminated media,such as sea water,neutral salts and brines.Alloy 625 is used in chemical processing,aerospace and marine engineering oil&gas,pollution control equipment and nuclear reactors.

2.National standards and common names

ASTM B446/564/443/446/444/704/705

AWS A5.14

ERNiCrMo-3

|

Trade Name |

USN |

% |

Ni |

Cr |

Mo |

Nb |

Fe |

Al |

Ti |

C |

Mn |

Si |

Co |

P |

S |

|

Inconel625 |

N06625 |

Min |

Bal |

20 |

8 |

3.15 |

|

|

|

|

|

|

|

|

|

|

Max |

23 |

10 |

4.15

|

5 |

0.4 |

0.4 |

0.1 |

0.5 |

0.5 |

1 |

0.015 |

0.015 |

4.Mechanical property

strength of extension:σb≥760Mpa

yield strength:σb≥345Mpa

ductility:δ≥30%

High temperature corrosion: Alloy 625 has excellent corrosion resistance and high oxidation performance. From low temperature to 980 degree, it can have good tensile performance and fatigue performance, as well as resistance to stress corrosion in the atmosphere of salt fog.