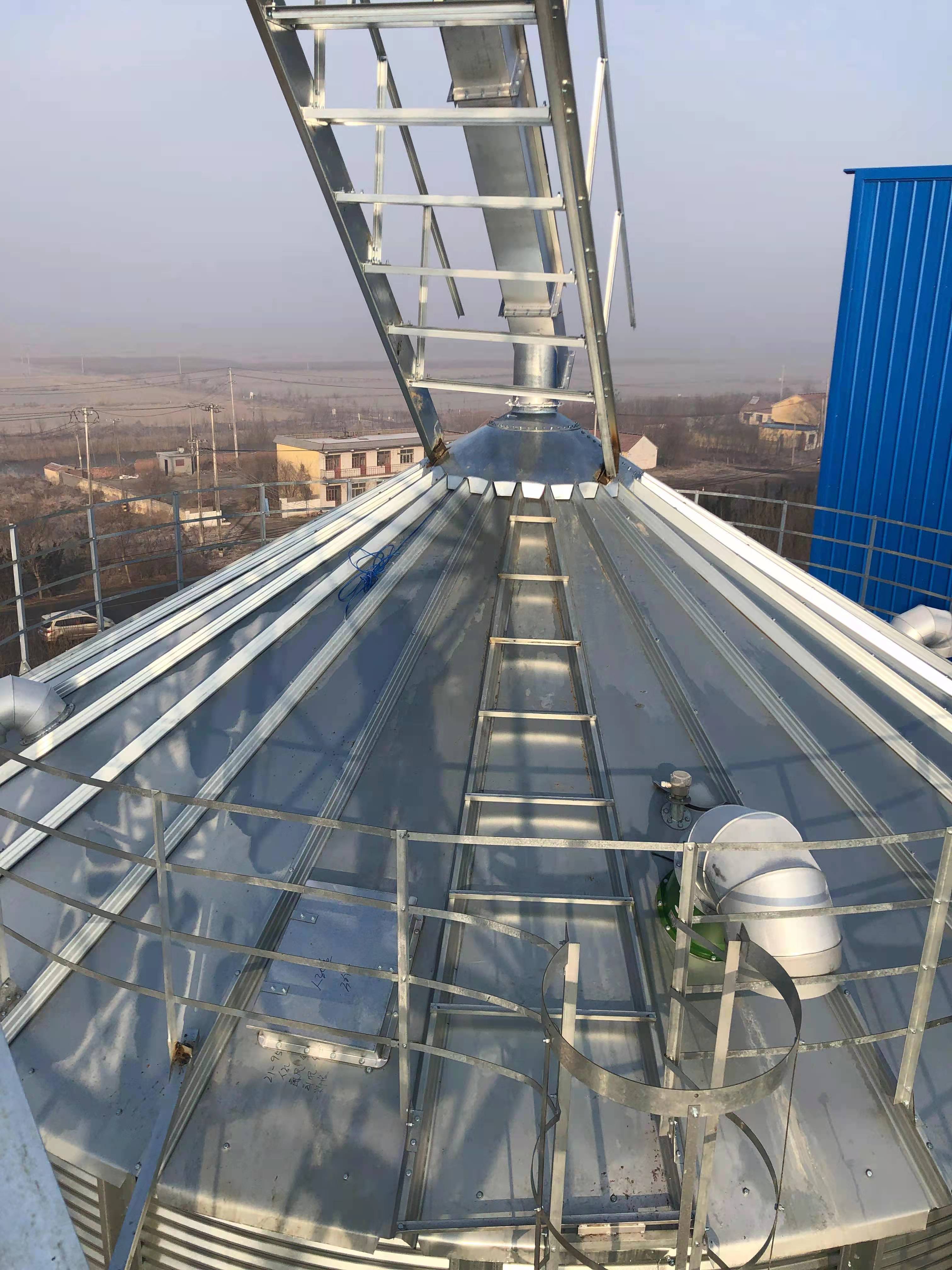

1. Our hopper bottom steel silo series is specially designed by senior engineers in our company, with high-quality galvanizing board.

2. Hopper angles can be 45° and 60°,among which 60° conical bottom is usually used to store larger pellet and powder materials with high viscosity.

3. All silos are precision engineered from high strength, 80mm x 14mm low profile corrugated steel plate, normally

galvanized to 275 g/m2.

4. The life cycle of the silos can come up to 30-50 years long. The products are designed comply with the national standard of GB50322-2001.

5. Our hopper bottom steel silos provide the best quality grain storage option available.Erection of the most popular 250t,500t and 1,000t silos is straightforward,and can typically be completed in around 10 days per silo.