- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Junbond

-

Model Number:

-

JB7132

-

Type:

-

Waterproof

-

Shelf life:

-

12 Months

-

Material:

-

100% Silicone

-

Color:

-

white, clear, black, grey, and other customer-made colors

-

Feature:

-

Water Resistance

-

Volume:

-

300ml, 280ml, 260ml, 240ml etc

-

Application:

-

Sealing Construction

-

Product name:

-

Silicone Sealant Glue

-

RTV:

-

acetic cure

-

Characteristic:

-

fast curing, excellent waterproof, weather resistent

-

Purpose:

-

glass, windows, doors, tile, ceramic, aluminium, wood, etc

Quick Details

-

CAS No.:

-

4253-34-3

-

Other Names:

-

gap filler

-

MF:

-

Mixture

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Junbond

-

Model Number:

-

JB7132

-

Type:

-

Waterproof

-

Shelf life:

-

12 Months

-

Material:

-

100% Silicone

-

Color:

-

white, clear, black, grey, and other customer-made colors

-

Feature:

-

Water Resistance

-

Volume:

-

300ml, 280ml, 260ml, 240ml etc

-

Application:

-

Sealing Construction

-

Product name:

-

Silicone Sealant Glue

-

RTV:

-

acetic cure

-

Characteristic:

-

fast curing, excellent waterproof, weather resistent

-

Purpose:

-

glass, windows, doors, tile, ceramic, aluminium, wood, etc

Junbond adhesive to fish glass aquarium silicone sealant water tank quick dry silicone sealant

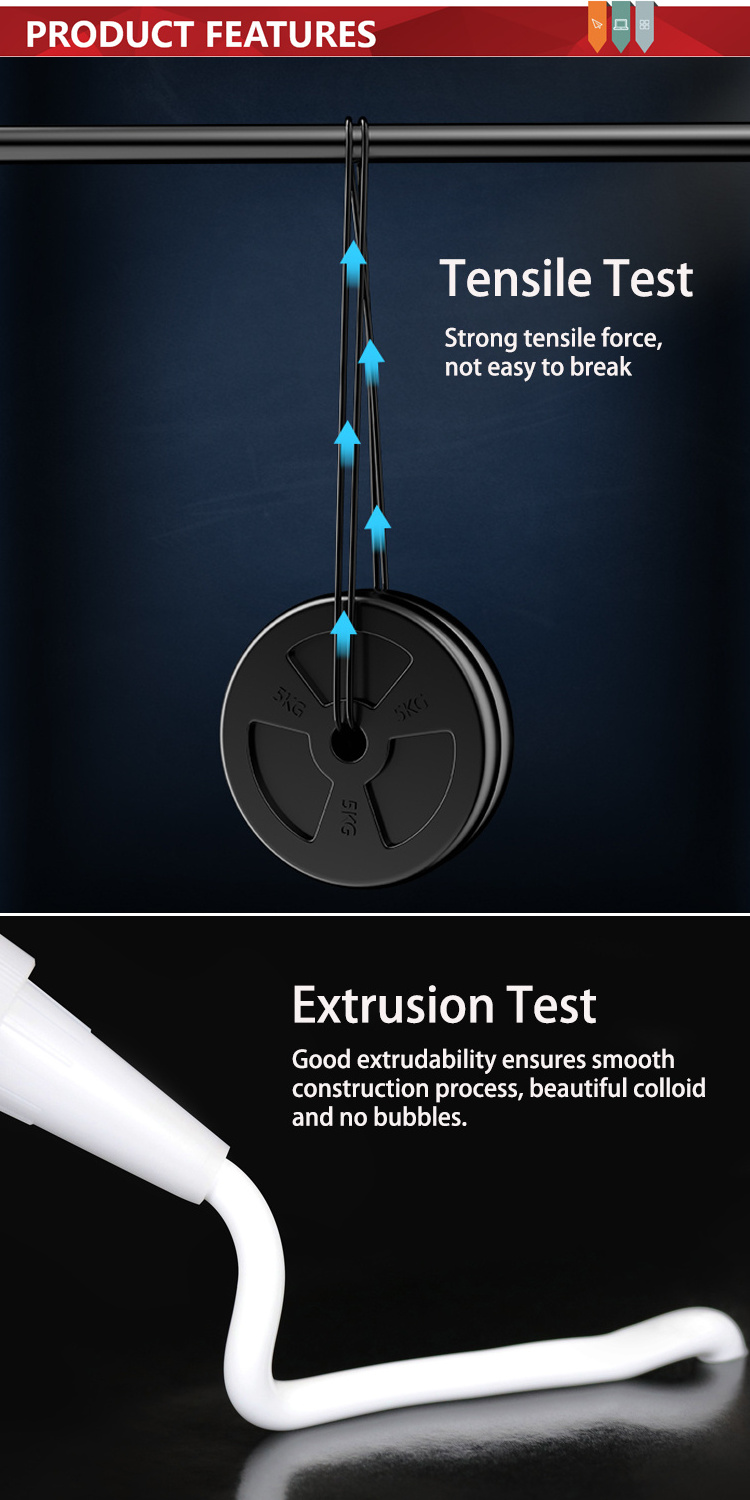

Product Feature:

1. Single component, acidic room temperature cure.

2. Excellent adhesion to glass and most building materials.

3. Cured silicone rubber elastomer with excellent long-term performance in the temperature range of -50° C to +100° C.

Main Application:

1. Caulking and sealing for interior and exterior decoration projects

2. Bonding and sealing of large floor-to-ceiling glass assemblies

3. Bonding and sealing of high-block glass cabinets and glass crafts

4. Large plate glass, small fish tanks less than 50cm in height, bonding and sealing of light roof craft glass structures

5. Other uses tested and applicable

How to use:

1. Before construction, a test of the adhesion of the sealant to the substrate should be carried out to confirm the suitability

of the product.

2. The substrate should be thoroughly cleaned with solvent or suitable cleaning agent, kept dry and glued within 30 minutes

after cleaning.

3. When gluing, ensure that the gap is completely filled, so that the gluing layer is dense and in close contact with the

surface of the substrate, and the gluing gap should be repaired within 5 minutes after gluing.

4. Suitable application temperature range 5°C to 40°C.

Warnings:

1. Use in a well-ventilated environment.

2. Use solvents in accordance with the appropriate safety regulations.

3. Keep the product out of the reach of children.

4. If uncured sealant melts your eyes, wash them immediately with water or seek medical attention.

Executive Standard: GB/T14683-2017

1. Single component, acidic room temperature cure.

2. Excellent adhesion to glass and most building materials.

3. Cured silicone rubber elastomer with excellent long-term performance in the temperature range of -50° C to +100° C.

Main Application:

1. Caulking and sealing for interior and exterior decoration projects

2. Bonding and sealing of large floor-to-ceiling glass assemblies

3. Bonding and sealing of high-block glass cabinets and glass crafts

4. Large plate glass, small fish tanks less than 50cm in height, bonding and sealing of light roof craft glass structures

5. Other uses tested and applicable

How to use:

1. Before construction, a test of the adhesion of the sealant to the substrate should be carried out to confirm the suitability

of the product.

2. The substrate should be thoroughly cleaned with solvent or suitable cleaning agent, kept dry and glued within 30 minutes

after cleaning.

3. When gluing, ensure that the gap is completely filled, so that the gluing layer is dense and in close contact with the

surface of the substrate, and the gluing gap should be repaired within 5 minutes after gluing.

4. Suitable application temperature range 5°C to 40°C.

Warnings:

1. Use in a well-ventilated environment.

2. Use solvents in accordance with the appropriate safety regulations.

3. Keep the product out of the reach of children.

4. If uncured sealant melts your eyes, wash them immediately with water or seek medical attention.

Executive Standard: GB/T14683-2017

|

No

|

Test Item

|

|

Unit

|

Actual results

|

|

|

1

|

Appearance

|

|

-

|

Smooth, no air bubbles, no lumps

|

|

|

2

|

Tack free time(at what % humidity)

|

|

min

|

4

|

|

|

3

|

Slump

|

Vertical

|

mm

|

0

|

|

|

|

|

Horizontal

|

mm

|

Not deformed

|

|

|

4

|

Extrusion

|

|

ml/min

|

1538

|

|

|

5

|

Shore A hardness /72h

|

|

-

|

26

|

|

|

6

|

Shrinkage

|

|

%

|

/

|

|

|

7

|

Effect of heat aging on

|

|

-

|

|

|

|

|

- Weight loss

|

|

%

|

13.0%

|

|

|

|

- Cracking

|

|

-

|

No

|

|

|

|

- Chalking

|

|

-

|

No

|

|

|

8

|

Tensile adhesion

|

|

Mpa

|

|

|

|

|

- Standard condition

|

|

|

0.53

|

|

|

|

- Immersion in water

|

|

|

/

|

|

|

|

- Dry at 100°C

|

|

/

|

|

|

|

9

|

Elongation at break

|

|

%

|

112

|

|

|

10

|

Specific gravity

|

|

g/cm3

|

1

|

|

|

11

|

Completely dry

|

|

hours

|

16

|

|

|

12

|

Temperature Resistence

|

|

°C

|

-50℃~150℃

|

|

|

13

|

Application Temperature

|

|

°C

|

4℃~40℃

|

|

|

14

|

Color

|

|

|

Transparent

|

|

Hot Searches