- Product Details

- {{item.text}}

Quick Details

-

Power:

-

OEM

-

Weight:

-

KG

-

Dimension(L*W*H):

-

OEM

-

Product name:

-

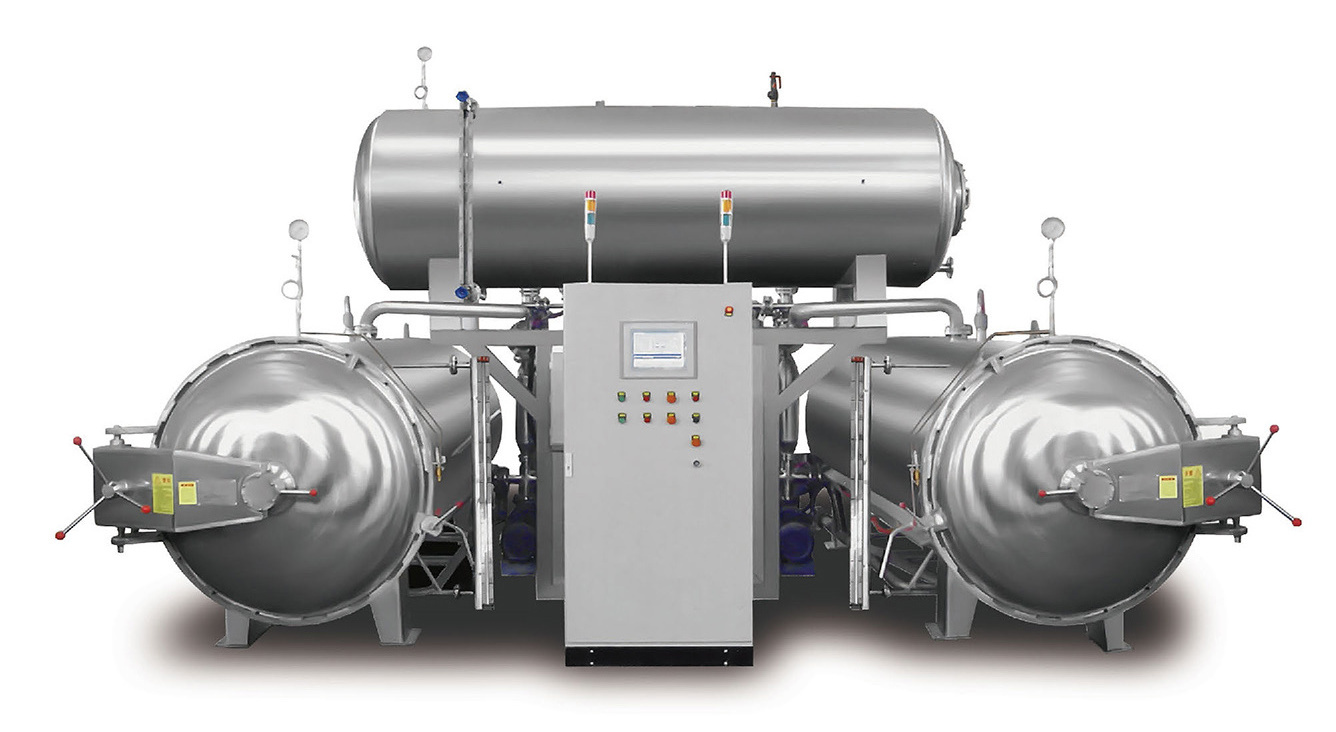

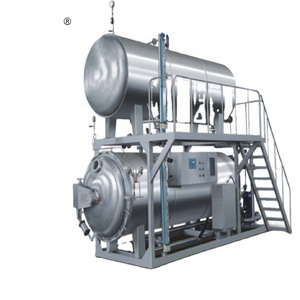

Sterilizer Autoclave Glass jars Retort/Tin can processing Retort

-

Application:

-

Canned Food&Pouch Food&Glass Jar

-

Material:

-

Stainless Steel SUS304

-

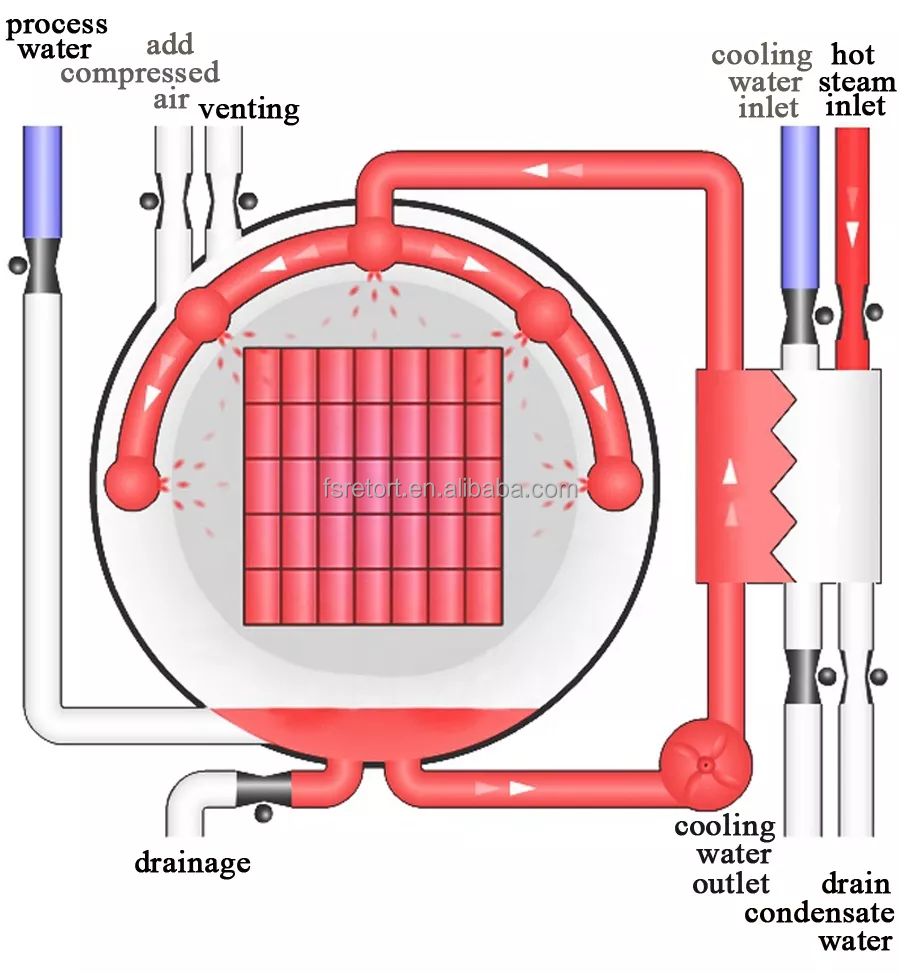

Sterilizing way:

-

Water-spray

-

Heating way:

-

Steam Boiler

-

Advantage:

-

High Efficiency

-

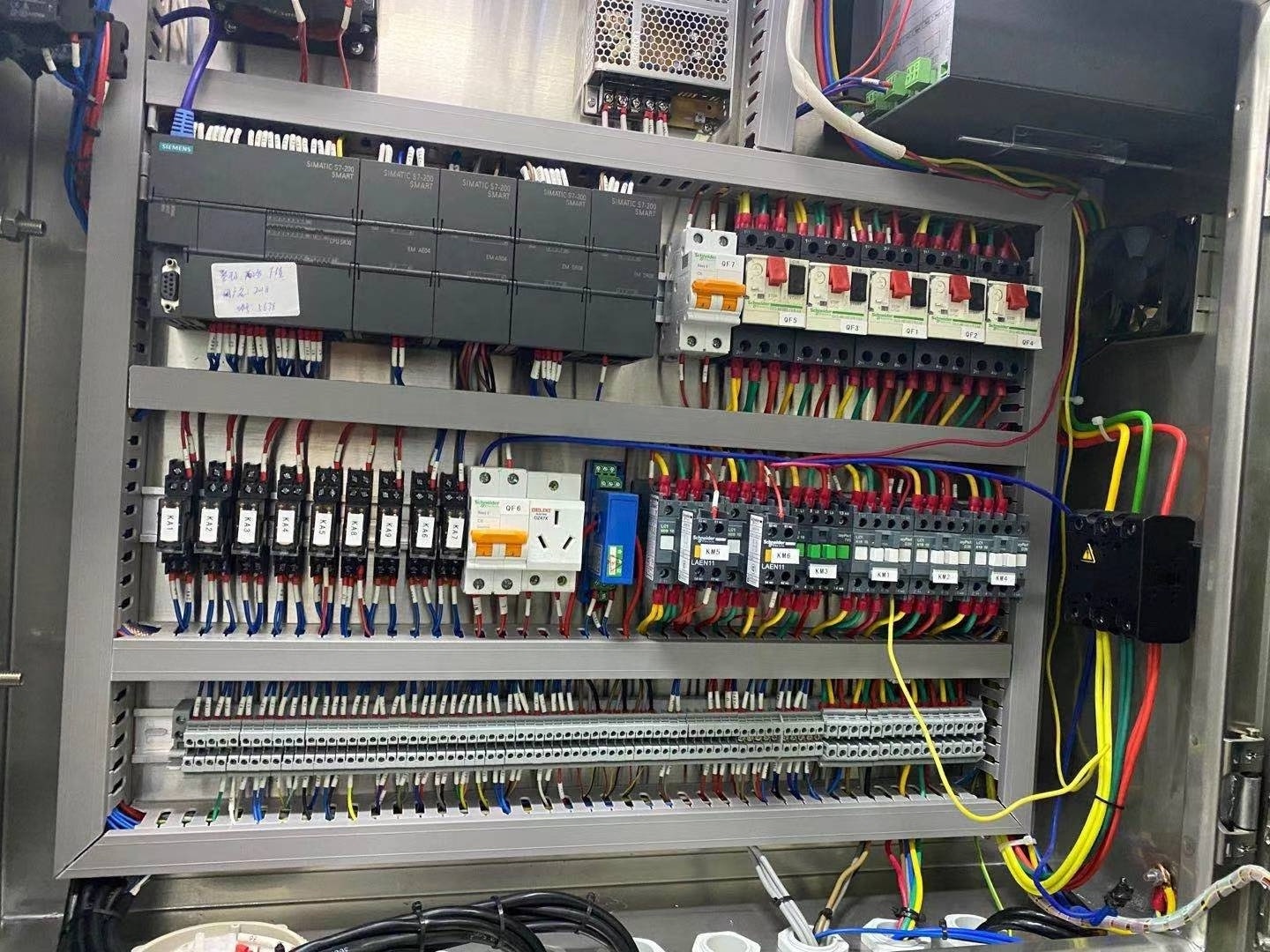

Control system:

-

Automatic Control System

-

Design Temperature:

-

147 Degree Centigrade

-

Design pressure:

-

0.35Mpa

-

Processing Types:

-

Sterilizing Packing Canned

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FS

-

Voltage:

-

220-380V

-

Power:

-

OEM

-

Weight:

-

KG

-

Dimension(L*W*H):

-

OEM

-

Product name:

-

Sterilizer Autoclave Glass jars Retort/Tin can processing Retort

-

Application:

-

Canned Food&Pouch Food&Glass Jar

-

Material:

-

Stainless Steel SUS304

-

Sterilizing way:

-

Water-spray

-

Heating way:

-

Steam Boiler

-

Advantage:

-

High Efficiency

-

Control system:

-

Automatic Control System

-

Design Temperature:

-

147 Degree Centigrade

-

Design pressure:

-

0.35Mpa

-

Processing Types:

-

Sterilizing Packing Canned

Industrial food Sterilizer / Glass jars bottle Retort Machine / Tin can processing Retort Sterilizer

1 Uniform water exchange mode realizes uniform temperature without dead angle.

2 High temperature instant sterilization.

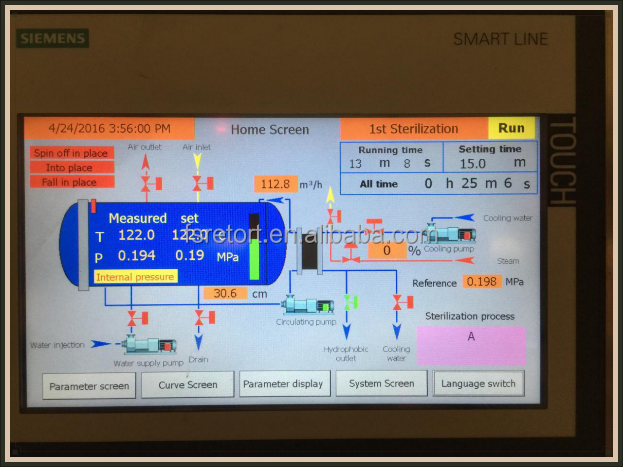

3 High sterilizing precision.

4 Energy saving.

5 All of the sterilizing courses can be controlled by computer PLC.

6 The sterilizing retort adopts simulative temperature control system,and multilevel heating system can be set.

7 The function of F value measurement.

|

Product name:Canned food sterilization equipment

|

|

|

|

|

|

|

||||||

|

Model

|

Diameter(mm)

|

Chamber length(mm)

|

Total length(mm)

|

Total width(mm)

|

Total height(mm)

|

Weight(kg)

|

||||||

|

FS-700

|

700

|

1200

|

2000

|

1000

|

1300

|

320

|

||||||

|

FS-900

|

900

|

1800

|

2600

|

1300

|

1600

|

660

|

||||||

|

FS-1000

|

1000

|

2400

|

2800

|

1500

|

1800

|

830

|

||||||

|

|

1000

|

2400

|

3000

|

1500

|

2000

|

900

|

||||||

|

FS-1200

|

1200

|

3600

|

3500

|

1800

|

2000

|

960

|

||||||

|

|

1200

|

3600

|

3800

|

1800

|

2500

|

1100

|

||||||

|

|

1200

|

3600

|

4000

|

1800

|

2500

|

1500

|

||||||

|

|

1200

|

3600

|

4500

|

1800

|

2500

|

1600

|

||||||

|

|

1200

|

3600

|

4800

|

1800

|

2500

|

1800

|

||||||