- Product Details

- {{item.text}}

Quick Details

-

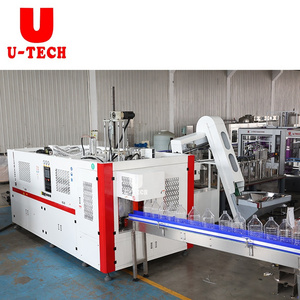

Brand Name:

-

Alps

-

Year:

-

2011

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

2.5*2*3.2m

-

Hollow part volume:

-

1L~10L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

60 mm

-

Screw Heating Power(kW):

-

12 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

550 mm

-

Mold Platen Size(Height)(mm):

-

500 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

1 m³/min

-

Die Head Heating Power(kW):

-

6.6 kW

-

Accumulator Capacity(L):

-

50 L

-

Power (kW):

-

50

-

Weight (T):

-

12

-

High Pressure Valve Brand:

-

SMC

-

Rotary Cylinder Brand:

-

AirTac

-

Keywords:

-

extrusion blow molding machine

-

Control:

-

PLC+Touch Screen

-

Extrusion Motor:

-

Siemens

-

Working station:

-

Single / Double

-

Hydraulic valve:

-

Yuken,Japan

-

Parison controller:

-

Japan MOOG 100 points

-

Hydraulic pump:

-

YUKEN,Japan

-

Certification:

-

CE,ISO...

Quick Details

-

Clamping Force (kN):

-

80

-

Output (kg/h):

-

65 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Alps

-

Year:

-

2011

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

2.5*2*3.2m

-

Hollow part volume:

-

1L~10L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

60 mm

-

Screw Heating Power(kW):

-

12 kW

-

Extruder Motor Power(kW):

-

22 kW

-

Mold Platen Size(Width)(mm):

-

550 mm

-

Mold Platen Size(Height)(mm):

-

500 mm

-

Air Pressure(MPa):

-

0.6 MPa

-

Air Comsumption(m³/min):

-

1 m³/min

-

Die Head Heating Power(kW):

-

6.6 kW

-

Accumulator Capacity(L):

-

50 L

-

Power (kW):

-

50

-

Weight (T):

-

12

-

High Pressure Valve Brand:

-

SMC

-

Rotary Cylinder Brand:

-

AirTac

-

Keywords:

-

extrusion blow molding machine

-

Control:

-

PLC+Touch Screen

-

Extrusion Motor:

-

Siemens

-

Working station:

-

Single / Double

-

Hydraulic valve:

-

Yuken,Japan

-

Parison controller:

-

Japan MOOG 100 points

-

Hydraulic pump:

-

YUKEN,Japan

-

Certification:

-

CE,ISO...

*PLC+touch screen: making the operation easy.

*Automatic malfunction alarm: with self-diagnosis,

making the malfunction clear at a glance.

*Center input die head: eliminating the knit line completely and making it easy to change the material and color.

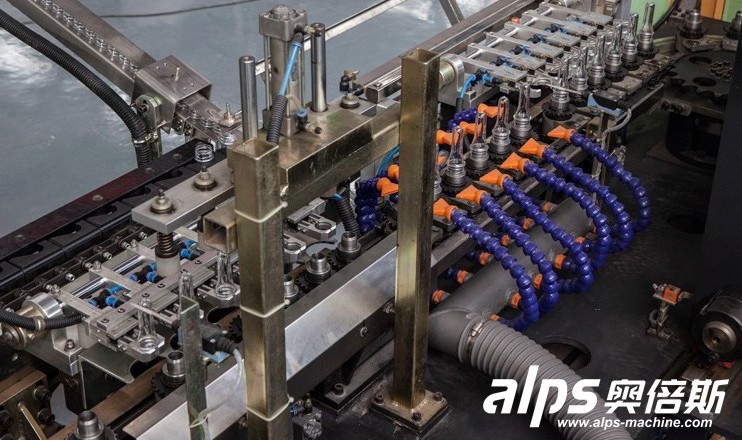

*Double linear guide rail: Unique “liner guide” to the clamping structure to ensure mold-lock uniform, knit line smoother, stable and quite working.

*Mould locking system: adopts Crank arm-Center lock design to provide the strong clamping force.

*High speed and efficient plasticizing: mixing well and ensuring the produce purity.

|

Specifications

|

Unit

|

Double station

|

|

|

||||

|

Machine model

|

|

EXB60D

|

EXB70D

|

EXB90D

|

||||

|

Material

|

|

PE,PP,PVC,PA etc.

|

|

|

||||

|

Max container capacity

|

L

|

2

|

5

|

12

|

||||

|

Number of die head

|

SET

|

|

|

|

||||

|

Machine dimension ( L×W×H )

|

M

|

3.1×2.1×2.5

|

3.4×2.2×2.5

|

4.5×3.5×2.9

|

||||

|

Machine Weight

|

T

|

6.3

|

8.2

|

11

|

||||

|

Clamping unit

|

|

|

|

|

||||

|

Mold platen size ( W×H )

|

MM

|

300×380

|

338×380

|

550×460

|

||||

|

Max mold size ( W×H )

|

MM

|

300×350

|

338×350

|

550×430

|

||||

|

Platen opening storke

|

MM

|

130-370

|

150-500

|

200-600

|

||||

|

Power

|

|

|

|

|

||||

|

Oil pump driving total power

|

KW

|

5.5

|

11

|

15

|

||||

|

Max driving total power

|

KW

|

20.5

|

33

|

52

|

||||

|

Average energy consumption

|

KW

|

15-18

|

23-25

|

31-34

|

||||

|

Blow pressure

|

Mpa

|

0.6

|

0.6

|

0.6

|

||||

|

Extruder unit

|

|

|

|

|

||||

|

Screw diameter

|

MM

|

55

|

70

|

90

|

||||

|

Screw L/D ratio

|

L/D

|

24:1

|

|

|

||||

|

Melting capacity

|

KG/HR

|

62

|

80

|

140

|

||||

|

Extruder power

|

KW

|

15

|

22

|

37

|

||||

|

Die head

|

|

|

|

|

||||

|

Max die-pin diameter

|

MM

|

95

|

135

|

180

|

||||

|

Center distance of double die head

|

MM

|

130

|

160

|

250

|

||||

|

Center distance of three die head

|

MM

|

110

|

110

|

130

|

||||

|

Center distance of four die head

|

MM

|

75

|

85

|

110

|

||||