- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1000 KG

-

Product Name:

-

robot stacker palletizer stacking machine

-

Control mode:

-

Computer and controller

-

Object to be transported:

-

Carton, turnover box, woven bag, etc

-

Keywords:

-

palletizer bag line machine

-

Function:

-

Automatic palletizing replaces manual work

-

Packing speed:

-

Max.500 Pcs/h

-

Machine type:

-

Vertical Automatic Packing Machine

Quick Details

-

Application:

-

Food, Beverage, Commodity, Chemical, Machinery & Hardware

-

Packaging Material:

-

Plastic, Paper

-

Place of Origin:

-

China

-

Weight:

-

1000 KG

-

Product Name:

-

robot stacker palletizer stacking machine

-

Control mode:

-

Computer and controller

-

Object to be transported:

-

Carton, turnover box, woven bag, etc

-

Keywords:

-

palletizer bag line machine

-

Function:

-

Automatic palletizing replaces manual work

-

Packing speed:

-

Max.500 Pcs/h

-

Machine type:

-

Vertical Automatic Packing Machine

Products Description

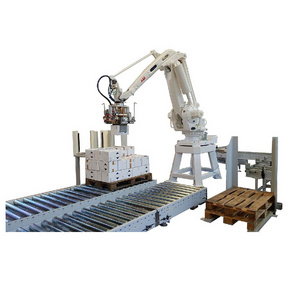

Column Rotary Palletizer

The column palletizing machine, also called stacking robot, robot palletizer, automatic palletizing machine, is a high-tech product of mechatronics. It can automatically arrange and stack the bags and cartons conveyed by the conveyor belt on the pallet or pallet according to the required grouping method and number of layers according to the customer's process requirements.

This equipment adopts PLC system control to realize intelligent operation management, easy to learn and understand, easy to master. Can greatly reduce labor and reduce labor intensity.

Vertical Automatic Palletizer is widely used in petrochemical, synthetic rubber, fertilizer, salt, building materials, grain, food, beverage, tobacco and alcohol, steel, postal, port and other industries of granules, powders, blocks, flakes, boxes, packaging and palletizing production line for solid and liquid materials such as boxes, bottles, bags, barrels, etc.

Product Parameter

|

Model

|

Column Type Rotary Palletizer

|

|

Machine height

|

3000mm

|

|

Weight range

|

10-50kg

|

|

Palletizing height

|

≤1.6m (gripper, clamp) ≤ 1.8m (suction cup)

|

|

Cross arm activity radius

|

700-1980 mm

|

|

Column effective travel

|

1850 mm

|

|

Rotation angle

|

±160°

|

|

Palletizing Speed

|

300-500 times/hour (depends on the material)

|

|

Palletizer Motor Power

|

6kw

|

|

Conveyor Motor Power

|

1.5kw

|

|

Pallet size reference

|

≤ 400*1600mm

|

Product Structure

A column type palletizing system is including the palletizer, carton or bag feeding roller conveyor and fences, its significance lies in its ability to streamline processes, optimize space, and enhance overall productivity within manufacturing and warehousing environments.

The single column stacker, also known as a single mast stacker, offers several advantages in warehouse and industrial settings. C

ompact dimensions, fully automatic, easy to install and operate,

international brand components.

Product Features

Single column stacker crane

1. Compact Design: Single column stackers have a compact design, making them suitable for narrow aisles and confined spaces. This allows for efficient use of warehouse space.

2. Maneuverability: Due to their compact design, single column stackers are highly maneuverable, allowing operators to navigate tight spaces with ease.

3. Versatility: These stackers are versatile and can be used for a variety of material handling tasks, such as lifting, transporting, and stacking pallets and other loads.

4. Cost-Effective: Single column stackers are often more cost-effective than larger, multi-column stackers, making them a practical choice for businesses with budget constraints.

5. Easy Maintenance: With fewer moving parts compared to multi-column stackers, single column stackers are generally easier to maintain and repair.

6. Operator Visibility: The single mast design provides excellent visibility for the operator, enhancing safety and efficiency during operation. These advantages make single column stackers a popular choice for businesses looking for efficient and cost-effective material handling solutions.

These advantages make single column stackers a popular choice for businesses looking for efficient and cost-effective material handling solutions.

Customer Site

Hot Searches