strain, elongation at the break ≤8%, good filler interlocking effect, and reduced filler usage. The stretching process makes the original scattered pore-distributed clusters of molecular chains re-aligned along the stretching direction, in a straight state, so that the tensile strength of the geogrid is greatly increased, the tensile strain and creep strain are significantly reduced, and the mechanical properties of the material is improved.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Bridge abutment, Bridge abutment

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

NETE

-

Model Number:

-

S2

-

Material:

-

Polypropylene

-

Product name:

-

biaxial geogrid

-

Color:

-

Black

-

Keywords:

-

geogrid

-

Feature:

-

High Tensile Strength

-

Usage:

-

Road Railway Construction

-

Package:

-

PP Woven Bags

-

Function:

-

Base Reinforcement

Quick Details

-

Warranty:

-

5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design

-

Application:

-

Bridge abutment, Bridge abutment

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

NETE

-

Model Number:

-

S2

-

Material:

-

Polypropylene

-

Product name:

-

biaxial geogrid

-

Color:

-

Black

-

Keywords:

-

geogrid

-

Feature:

-

High Tensile Strength

-

Usage:

-

Road Railway Construction

-

Package:

-

PP Woven Bags

-

Function:

-

Base Reinforcement

Products Description

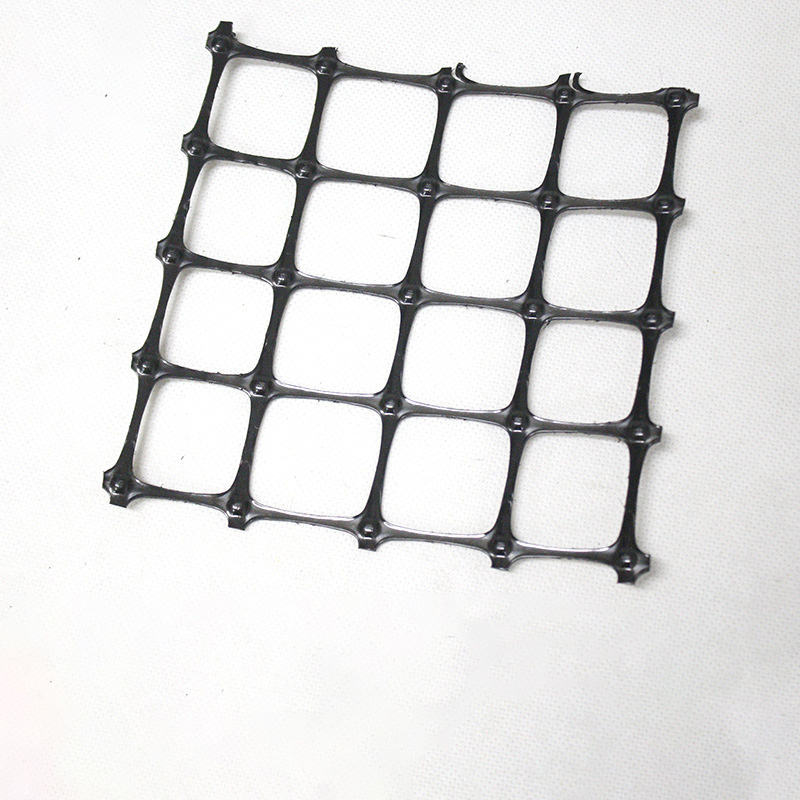

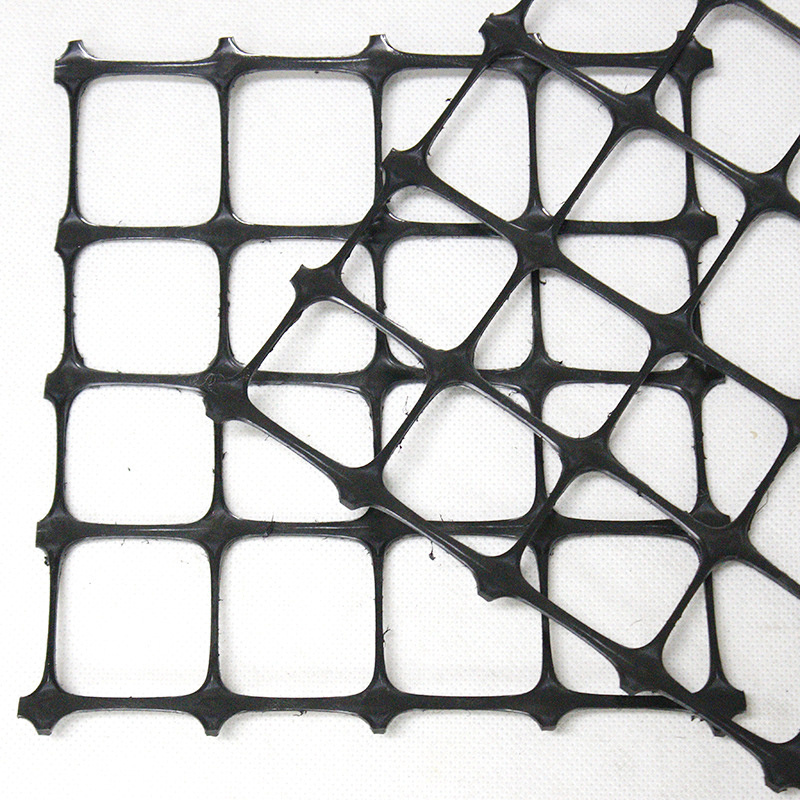

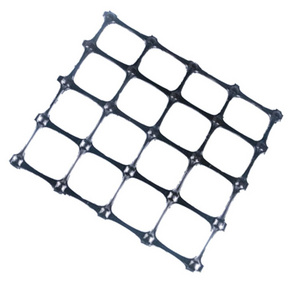

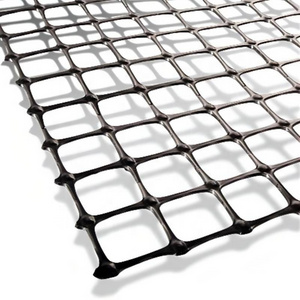

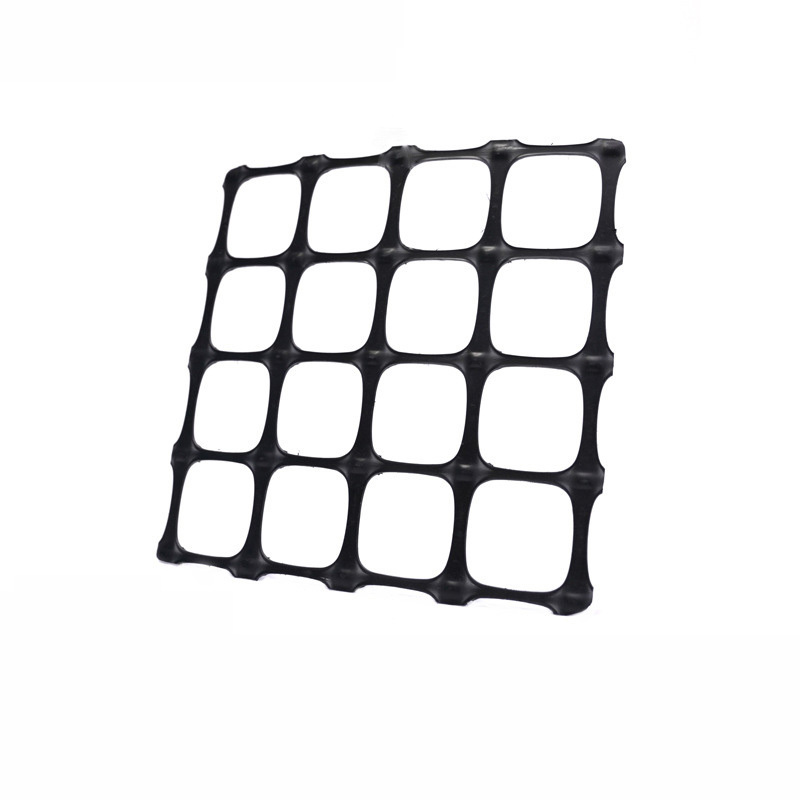

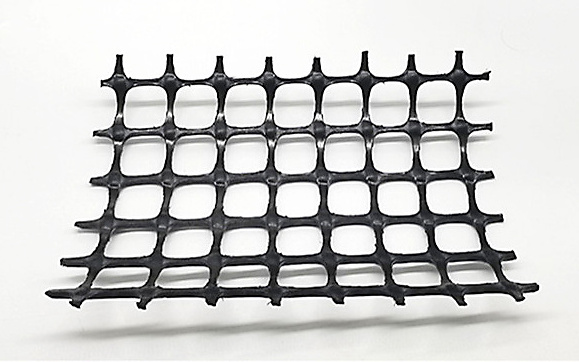

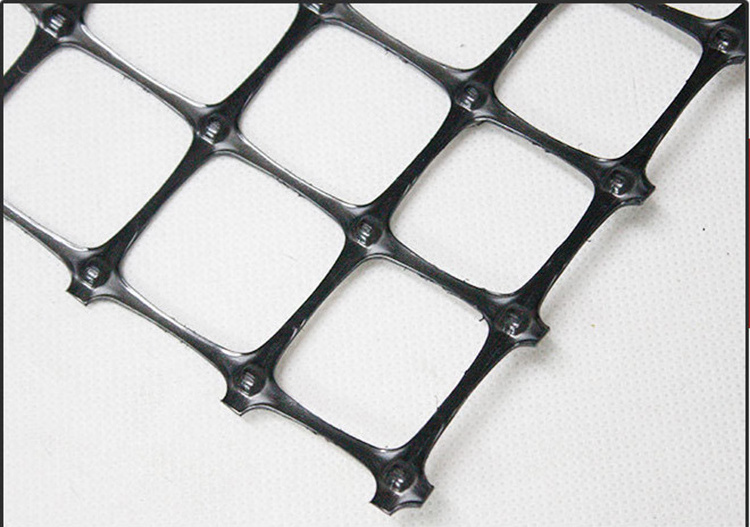

Stretched plastic geogrid highway construction bridge abutment road construction reinforcement PP biaxial geogrid

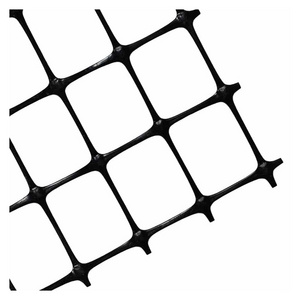

Biaxial geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforcement material.

Biaxial Geogrids

Very high radial secant stiffness value, high resistance to biological and chemical degradation, very high strength under low

strain, elongation at the break ≤8%, good filler interlocking effect, and reduced filler usage. The stretching process makes the original scattered pore-distributed clusters of molecular chains re-aligned along the stretching direction, in a straight state, so that the tensile strength of the geogrid is greatly increased, the tensile strain and creep strain are significantly reduced, and the mechanical properties of the material is improved.

strain, elongation at the break ≤8%, good filler interlocking effect, and reduced filler usage. The stretching process makes the original scattered pore-distributed clusters of molecular chains re-aligned along the stretching direction, in a straight state, so that the tensile strength of the geogrid is greatly increased, the tensile strain and creep strain are significantly reduced, and the mechanical properties of the material is improved.

Specification

|

Item No.

|

Longitudinal/transverse tensile strength (kN/m)

|

When longitudinal/transverse 2% elongation

Tensile strength (kN/m) |

Tensile strength at 5% longitudinal/transverse elongation (kN/m)

|

Welding point limit

Peel strength (N) |

Nominal elongation (%)

|

UV intensity retention rate (%)

|

Mass per unit area (g/m2)

|

|

GGR/PET/BW30-30

|

≥ 30.0

|

≥ 12.0

|

≥ 22.0

|

≥ 100

|

≤8

|

≥80

|

≥280

|

|

GGR/PET/BW50-50

|

≥ 50.0

|

≥ 21.0

|

≥ 39.0

|

|

|

|

≥420

|

|

GGR/PET/BW80-80

|

≥ 80.0

|

≥ 36.0

|

≥ 64.0

|

|

|

|

≥600

|

Details Images

Application

Certification

Hot Searches