- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1-5%

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YISHENG

-

Dimension(L*W*H):

-

3200X650X1600MM

-

Weight:

-

750 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Marketing Type:

-

New Product 2020

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Powder

-

Filling Accuracy:

-

1-5%

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YISHENG

-

Dimension(L*W*H):

-

3200X650X1600MM

-

Weight:

-

750 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Marketing Type:

-

New Product 2020

Linear type coffee powder cup packing machine advantage:

automatic dropping cups

> automatic once filling and press coffee powder tightly

> automatic suck and put pre-cut aluminum lids

> automatic twice sealing

> automatic outing cups.

> With UV lights station system

> Automatic cleaning station for a better seal

> Automatic outing cups

> Touch Screen with English and Chinese

> 2 s top button s

> Alarm light

> 2 plastic glass door on each sealing

all the functions can be increase or decrease according to your requirements .

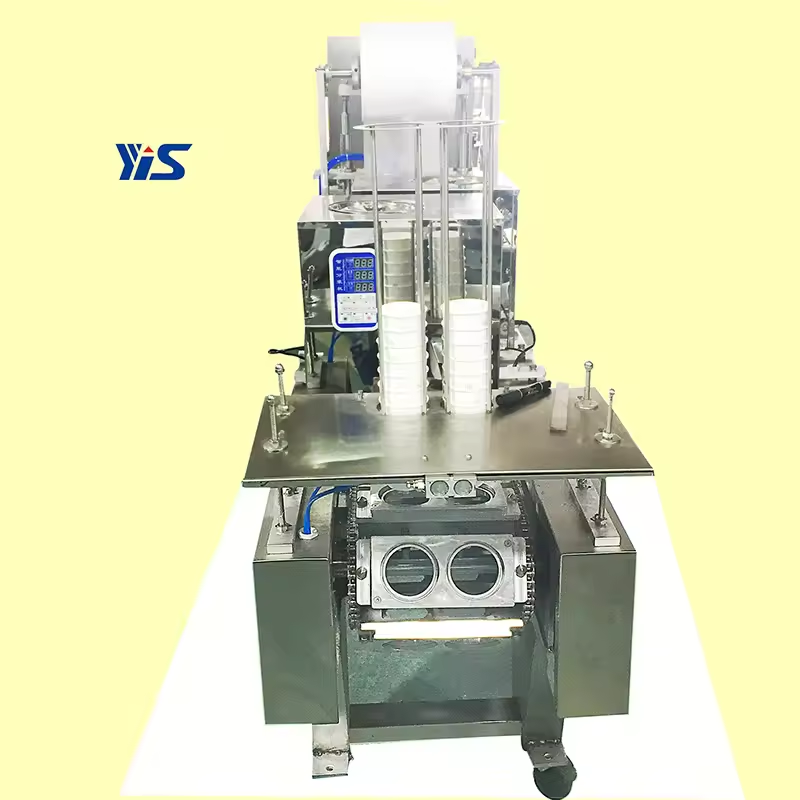

1- Technical Data

|

Model |

BG-1 |

BG-2 |

BG-6 |

|

Capacity(bowls/h) |

500-800 |

1400-1600 |

4800-5300 |

|

power of motor |

2Kw |

3Kw |

7kw |

|

power for whole |

4kw |

6kw |

8kw |

|

electrical |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

|

gross weight |

600kg |

650kg |

700kg |

|

size (L*W*H)mm |

300*80*160 |

320*80*160 |

400*70*160 |

|

used pressure |

0.65-0.7Mpa |

0.65-0.7Mpa |

0.65-0.7Mpa |

|

air consumption |

0.45m3/h |

0.6m3/h |

0.7m3/h |

2- Equipment lists:

|

Name |

Brand |

|

PLC |

OMRON |

|

TOUCH SCREEN |

WEINVIEW |

|

Motor |

Dingyi |

|

Solenoid valve |

JELPC |

|

A.C contactor |

Schneider |

|

temperature controller |

Xinpu |

|

Relay |

Delixi |

|

Breaker |

Delixi |

|

Cutter |

Ruipu |

|

Reducer |

Bopai |

|

Pneumatic element |

Aix |

3- Working Process :

1) automatic dropping cups

2) automatic once filling and press tightly coffee powder

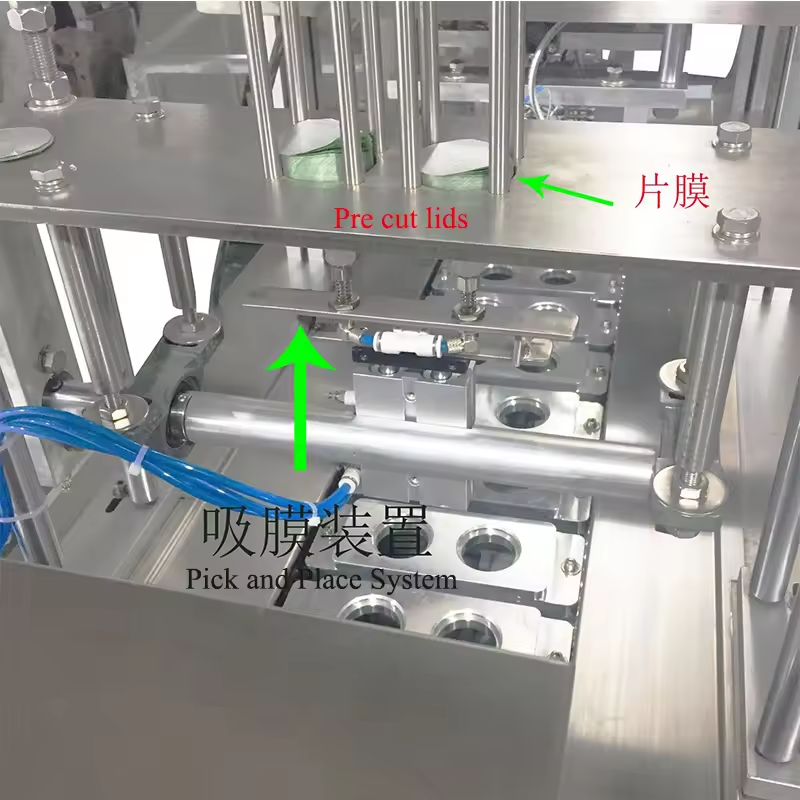

3) automatic suck and put pre-cut aluminum lids

4) automatic twice sealing

5) automatic outing cups.

6) With UV lights station system

7) Automatic cleaning station for a better seal

8) Automatic outing cups

9) Touch Screen with English and Chinese

Notice: above steps may change upon the different capsule product kind.

4- Machine S tructure :

A: control system: Controller: PLC, Japan Omron control parts.

All the machine are pneumatic, to make sure the machine can operation stable .

B: seal device: Two-heat seal, to seal well .

C: molds: use acid proof molds .

D: All the machine Frame outsourcing are 304 stainless stee l, but the filling system and all touch the products are all made of 304 stainless steel .

E: cylinder: Taiwan "AIRTAC"

F: electric parts: are all famous brand from all over the world.

G: Filling system: piston type

H: Touch Screen

5- Automatic Cup Dispenser

6- Automatic Auger Filler

7- Automatic Pick and Place System

8- Automatic Press System

9- Automatic Two Times Sealing

10- PLC Touch Screen