- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

39000*1300*2500mm(TSE65-III)

-

Weight:

-

1 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V/50HZ

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Product name:

-

Automatic Instant mini corn flakes machine

-

Function:

-

Multi-function

-

Material:

-

Stainless steel

-

Raw material:

-

Grains

-

Output:

-

100-500kg/h

-

Packing:

-

Wooden Box Outsie

-

Power:

-

90-150KW

Quick Details

-

Machinery Capacity:

-

100-150 kg/h

-

Brand Name:

-

Sunward

-

Year:

-

New

-

Dimension(L*W*H):

-

39000*1300*2500mm(TSE65-III)

-

Weight:

-

1 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V/50HZ

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Product name:

-

Automatic Instant mini corn flakes machine

-

Function:

-

Multi-function

-

Material:

-

Stainless steel

-

Raw material:

-

Grains

-

Output:

-

100-500kg/h

-

Packing:

-

Wooden Box Outsie

-

Power:

-

90-150KW

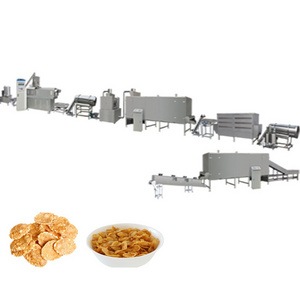

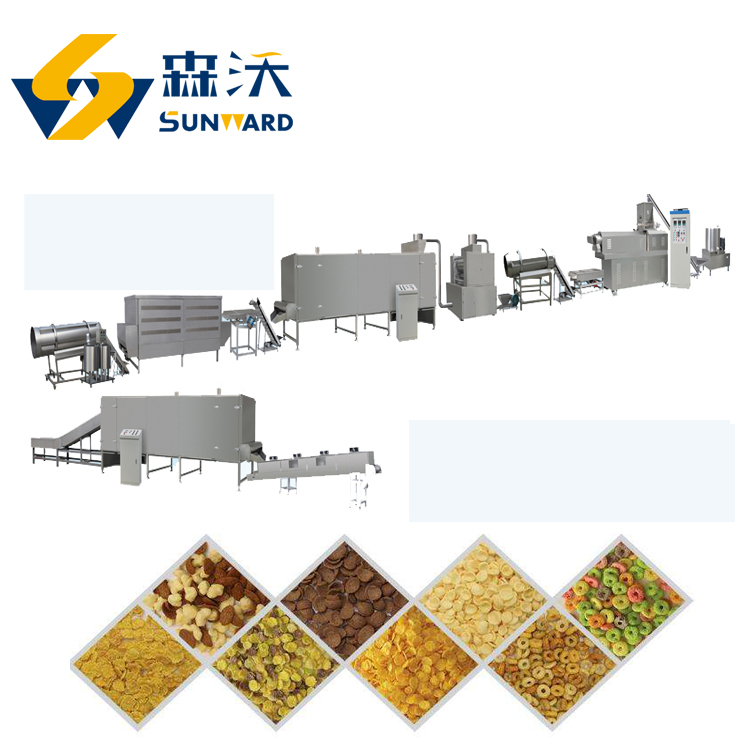

Automatic Instant mini corn flakes machine /

corn flake processing line / breakfast cereal maker

1.1 Breakfast cereals/corn flakes/maize flakes/oat flakes Introduction

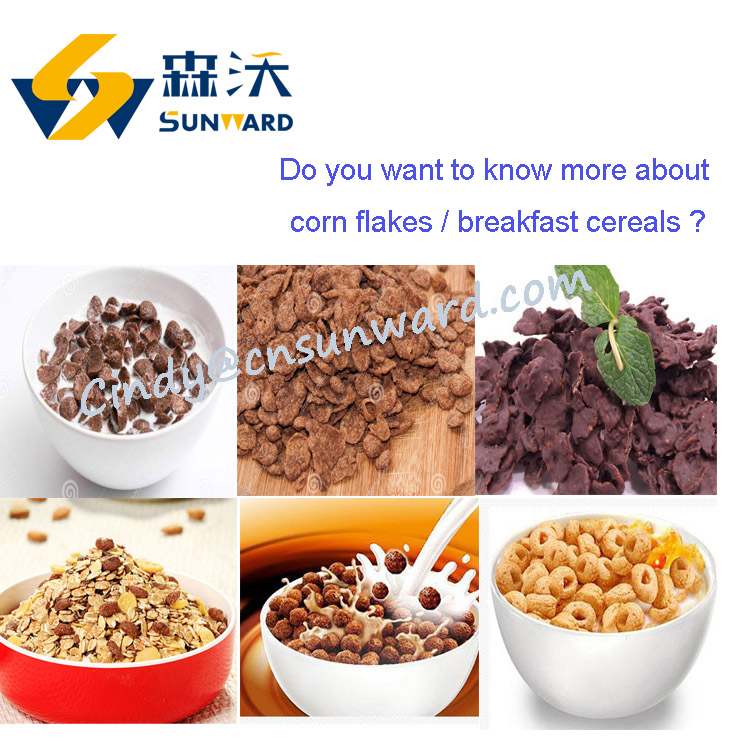

Breakfast cereals /corn flakes i s one kind of crispy food, with the advantages of hard to be steeped broken and strong grain taste. It is crispy flakes which are made from corn meal and the othe r grains powder. breakfast cereal corn flakes making machine include mixing,extruding,flaking,drying,high temperature baking, flavoring and cooling. It can be eaten like snack, and be eaten with milk or coffee as well. By changing moulds and production line can make different shapes of puffed food. Such as ring, ball, flake,star,letter etc.

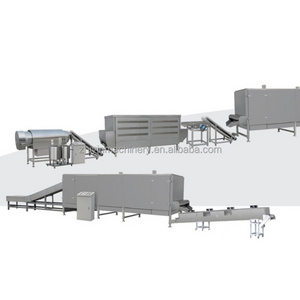

1.2 The whole line of Breakfast cereals/corn flakes/maize flakes/oat flakes Introduction

Mixer→Screw conveyor→Twin- screw extruder→Vibrating screen→Drum-type dryer→Air conveyor→Flaking machine→Air conveyor→Dryer→Hoister→Vibrating screen→High-temperature inflated oven→Flavoring line→climbing dryer→Cooling machine

1.3 Voltage of breakfast cereal processing line

Three phases: 380V/50Hz, Single phase: 220V/50Hz. we can make it according to customers' Local voltage according to different countries.

1.4 Raw materials of breakfast cereal processing line

adopts c orn/wheat as raw materials meanwhile mixing with water and oil.

1.5 Capacity of breakfast cereal processing line

100kg/h-500kg/h(Automatic Instant mini corn flakes machine / corn flake processing line / breakfast cereal maker )

1.6 Samples of Breakfast cereals/corn flakes/maize flakes/oat flakes

|

Parameter of breakfast cereal processing line |

|||

|

Model |

TSE-65-III |

TSE-70 |

TSE-85 |

|

Installed capacity(kw) |

130 |

160 |

190 |

|

Real power(kw/h) |

90 |

120 |

150 |

|

Output(kg/h) |

100-150 |

200-260 |

300-500 |

|

Dimension(mm) |

39000*1300*2500 |

41000*1500*2500 |

43000*3500*4300 |

2.1 Twin-screw extruder

1.The main extruder adopts

frequency speed controlling

with high automation.

2.The screws are made of the

stainless steel and special craft

, which has the advantage of durable usage, high pressure,and longer life.

3.The

forced lubrication system

,which can guarantee the equipment transmission life longer.

4.

Auto-temperature control system and self-cleaning

,which makes it more convenient.

5.It has the widest range of applications and can produce different products with

different equipment and models.

2.2 Multi-layer dryer

1.We have

four types of dryers

,

which includes fuel ovens, gas ovens, electric ovens, and high temperature inflated ovens (used to produce corn flakes).

2.Dryer is compact, has small dry area and a largesuperficial area. It also features

small scale of heat elimination and high thermal effciency.

3.Mesh belt conveyors and thermal insulation boards all use

stainless steel material

,

making the equipment clean and sanitary.

2.3 Cooling machine

1.General length is 5 meters, but we can made it according to our customers' requirement.